Silicon rubber composition and production thereof

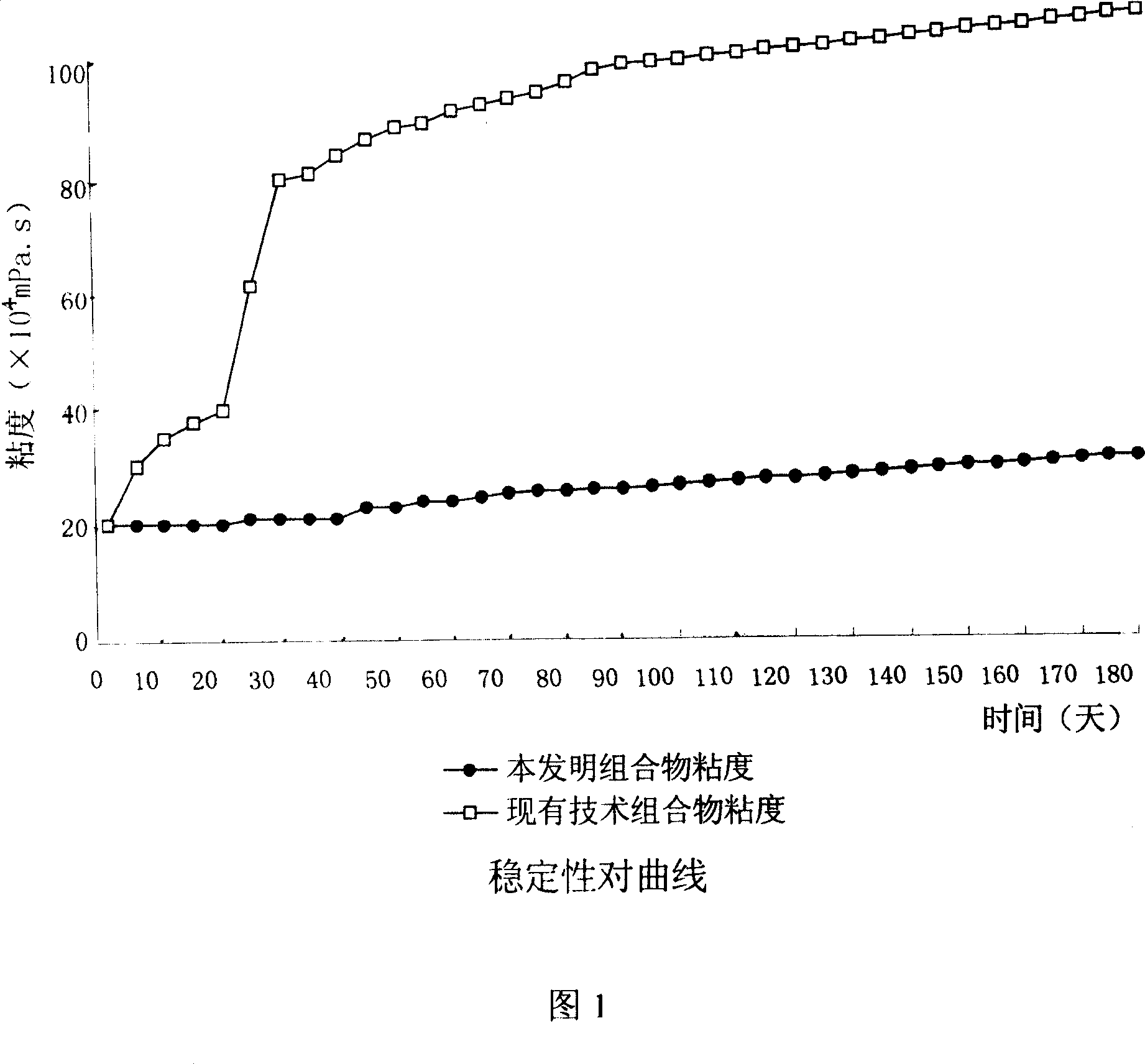

A technology of silicone rubber composition and polymer, which is applied in the field of two-component addition type liquid silicone rubber composition and preparation thereof, can solve the problems of poor mechanical properties of rubber products, unsuitable for injection molding and high composition viscosity, and achieves Strong anti-structural ability, good fluidity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

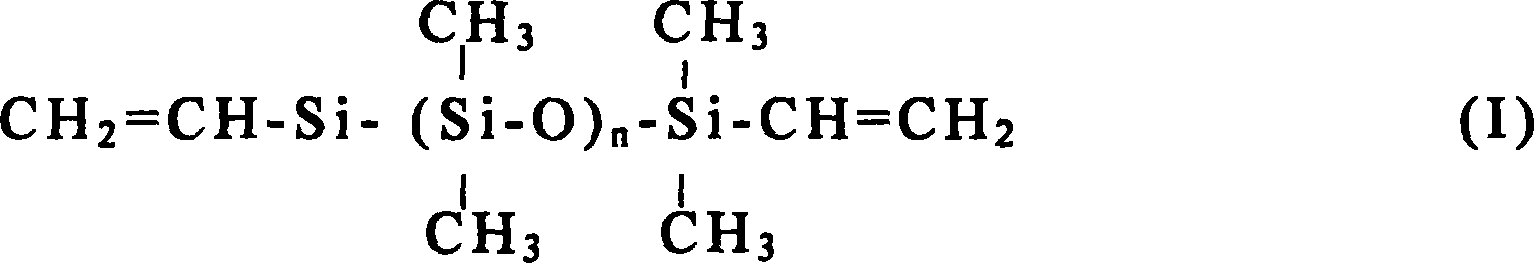

[0069] The basic polymer consists of the first polymer of η=5000±1000mPa.s, n=200~250; the second polymer of viscosity η=20000±2000mPa.s, n=500~600; viscosity η=70000±10000mPa. s, the third polymer with n=900~1200; the structural formula is as the previous formula (I), mixed in a weight ratio of 30:30:20.

[0070] Prepare the base:

[0071] A total of 30 parts by weight (15 parts each) of the above-mentioned liquid base polymer of 70 parts by weight (reserving 30 parts by weight), German Wacker T40 and Nipsil. 9 parts of dimethoxysilane, 2 parts of water and 0.1 part of stearate, stir evenly in a kneader, raise the temperature to 140°C, heat treat under vacuum for 2.5 hours, cool to room temperature, and then add the reserved 30 parts of base polymer , and further mix uniformly to obtain the base glue.

[0072] To prepare component A:

[0073] Add platinum siloxane complex to 100 parts by weight of gum base and mix evenly so that the concentration of platinum atoms is 30ppm...

example 2

[0080] The basic polymer includes the first polymer with viscosity η=5000±1000mPa.s, n=200~250; the second polymer with viscosity=20000±2000mPa.s, n=500~600; viscosity η=60000±10000mPa. s, the third polymer with n=900-1200; and the silicone rubber raw rubber with a weight average molecular weight of 450,000-650,000, the weight ratio of which is 30:30:20:10.

[0081] Prepare the base:

[0082] A total of 30 parts by weight (15 parts each) of the above-mentioned liquid base polymer of 70 parts by weight (reserving 30 parts by weight), German Wacker T40 and Nipsil. 9 parts of dimethoxysilane, 2 parts of water and 0.1 part of stearate were stirred evenly in a kneader, and then the temperature was raised to 140°C, heat treated in vacuum for 2.5 hours, cooled to room temperature, and the reserved 30 parts The base polymer is further mixed evenly to obtain the base rubber.

[0083] To prepare component A:

[0084] Add platinum siloxane complex to 100 parts of gum base and mix even...

example 3

[0094] The basic polymer includes the first polymer with viscosity η=5000±1000mPa.s, n=200~250; the second polymer with viscosity η=20000±2000mPa.s, n=500~600; viscosity η=60000±10000mPa .s, the third polymer of n=900~1200; Molecular weight is the raw rubber of 45~650,000; And the 5th polymer η=800mPa.s, the molar weight of vinyl: Vi%=4%mol / gram polysiloxane. The mass ratios of the five components in the base polymer are respectively:

[0095] (a) 30:30:20:10:0;

[0096] (b) 30:30:20:10:10;

[0097] (c) 30:30:20:10:20.

[0098] Prepare base rubber, A / B component by the same method as Example 1 and Example 2, and inject A and B components into silicone rubber products, corresponding to the above-mentioned three kinds of formulas (a), (b), and (c), to prepare Silicone rubber products (a), (b) and (c) were obtained, and their mechanical properties comparison table is shown in Table 2.

[0099] mechanical properties

Silicone rubber products (a)

Silicone rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com