Spiral turbo-hydroturbine

A technology of spiral turbines and water turbines, applied in hydroelectric power generation, mechanical equipment, machines/engines, etc., can solve the problems of large water energy, which affects the improvement of water turbine power and water energy conversion efficiency, and achieves high water energy utilization and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

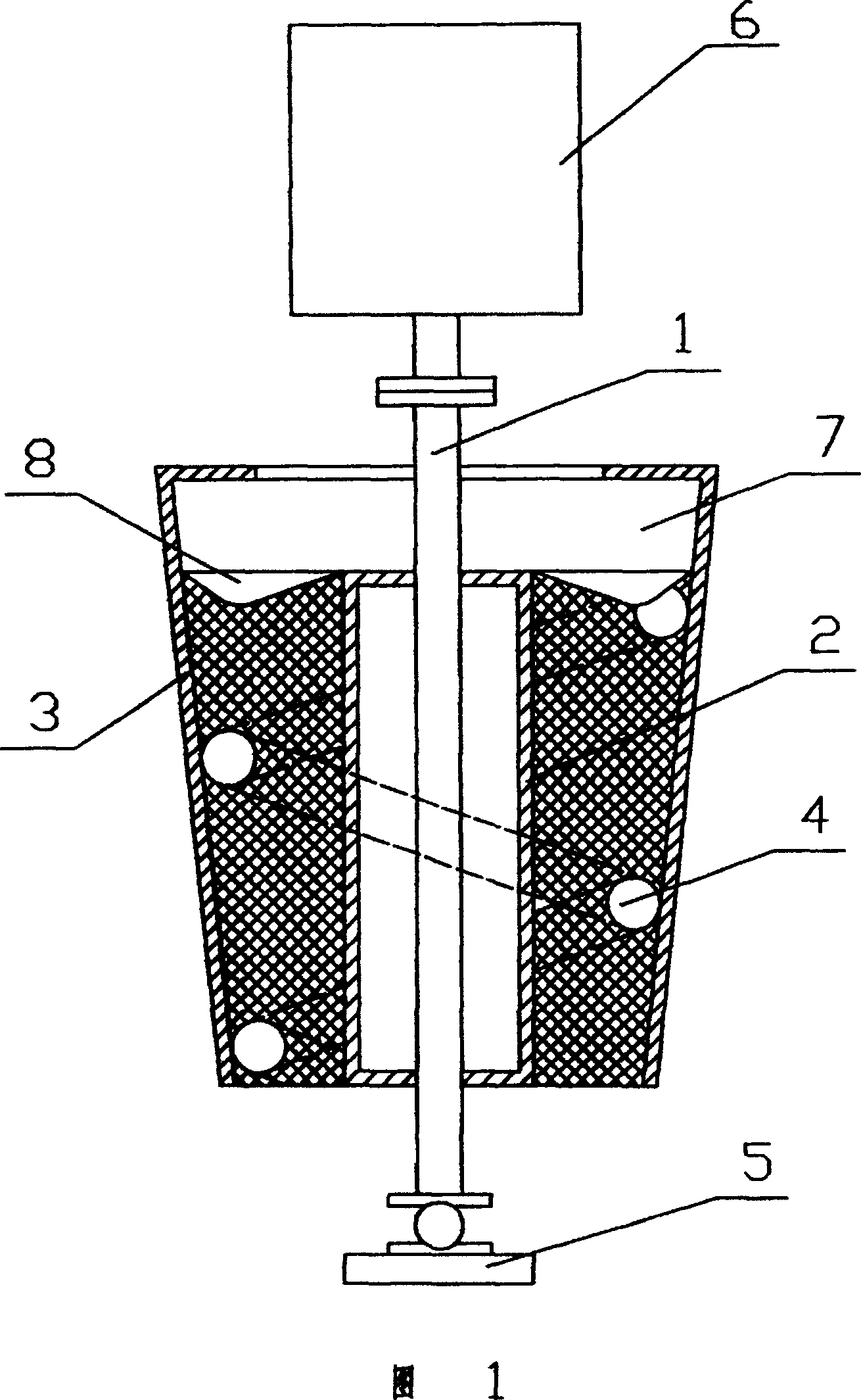

[0012] Embodiment 1: As shown in Figure 1, the screw turbine includes a main shaft 1, the main shaft 1 is vertically arranged, and the inner vertical tube 2 and the outer vertical tube 3 are fixedly installed on the main shaft 1, and the inner vertical tube 2 and the outer vertical tube 3 There is a spiral water flow channel 4 between them, the lower end of the main shaft 1 is provided with a support seat 5, the upper end of the main shaft is connected with the generator 6, and the top of the outer vertical tube 3 is provided with a water collection chamber 7, and the spiral water flow channel 4 The top of the rotor is provided with a plurality of impact dimples 8, and the outer surface shape of the impact dimples 8 is similar to the upper surface of the blade turbine, which is beneficial to the conversion of hydrodynamic energy.

[0013] The outer vertical cylinder 3 fixedly installed on the main shaft 1 is conical, and the spiral water flow channel 4 is a conical spiral chann...

Embodiment 2

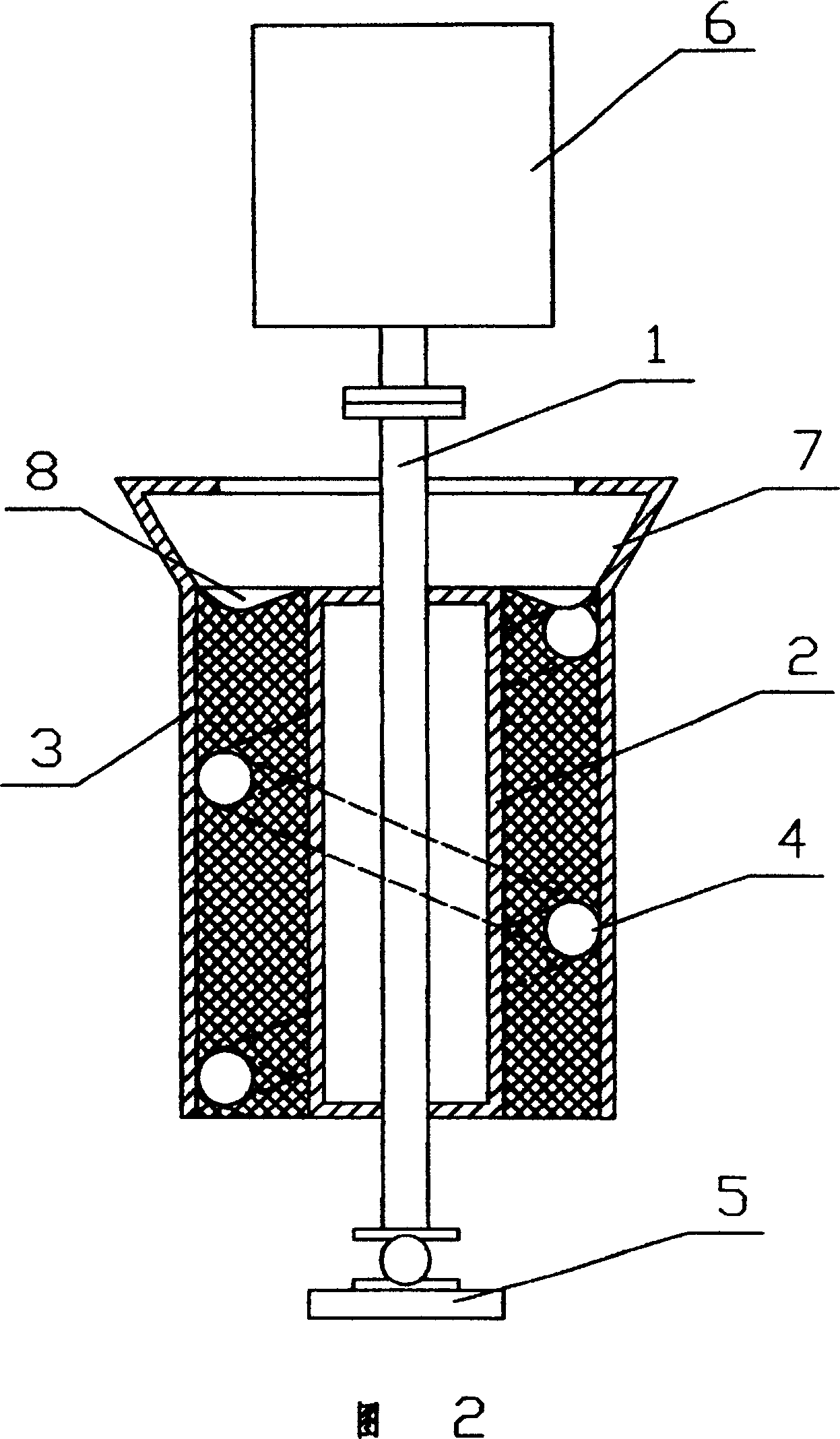

[0014] Embodiment 2: As shown in Figure 2, the screw turbine includes a main shaft 1, the main shaft 1 is arranged vertically, and the inner vertical tube 2 and the outer vertical tube 3 are fixedly installed on the main shaft 1, and the inner vertical tube 2 and the outer vertical tube 3 There is a spiral water flow channel 4 between them, the lower end of the main shaft 1 is provided with a support seat 5, the upper end of the main shaft is connected with the generator 6, and the top of the outer vertical tube 3 is provided with a water collection chamber 7, and the spiral water flow channel 4 The top of the rotor is provided with a plurality of impact dimples 8, and the outer surface shape of the impact dimples 8 is similar to the upper surface of the blade turbine, which is beneficial to the conversion of hydrodynamic energy.

[0015] The outer tube 3 fixedly installed on the main shaft 1 is cylindrical, and the spiral water flow channel 4 is a cylindrical spiral channel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com