Pain-relieving

A technology of babu ointment and realgar, applied in the direction of non-central analgesics, medical preparations containing active ingredients, medical formulas, etc., can solve the problems of increased blood lead and urine lead content, inconvenient use and storage, and effective Chinese herbal medicine. Low ingredients and other issues, to achieve high drug loading, non-allergic transdermal absorption, and facilitate transdermal absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

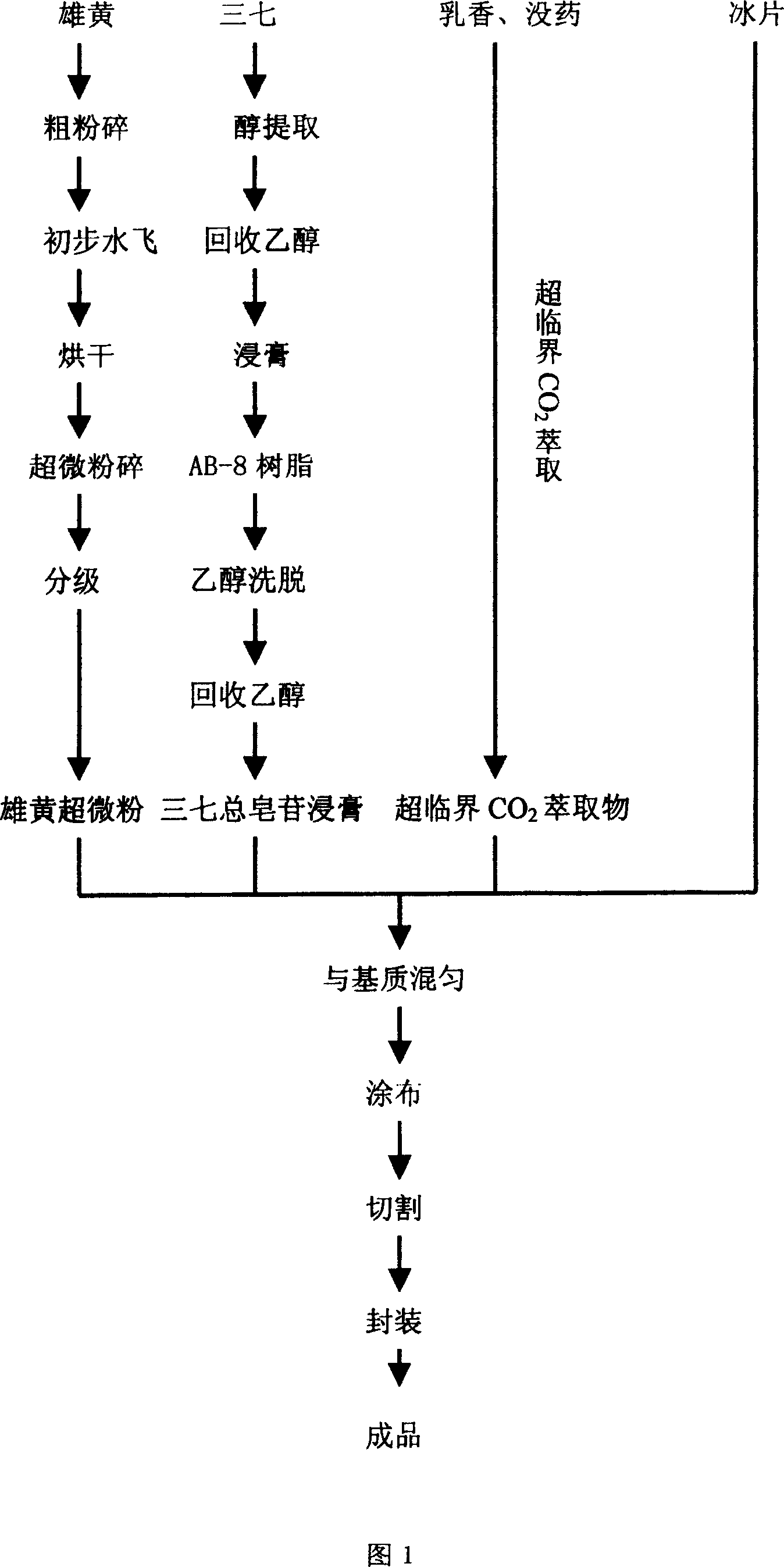

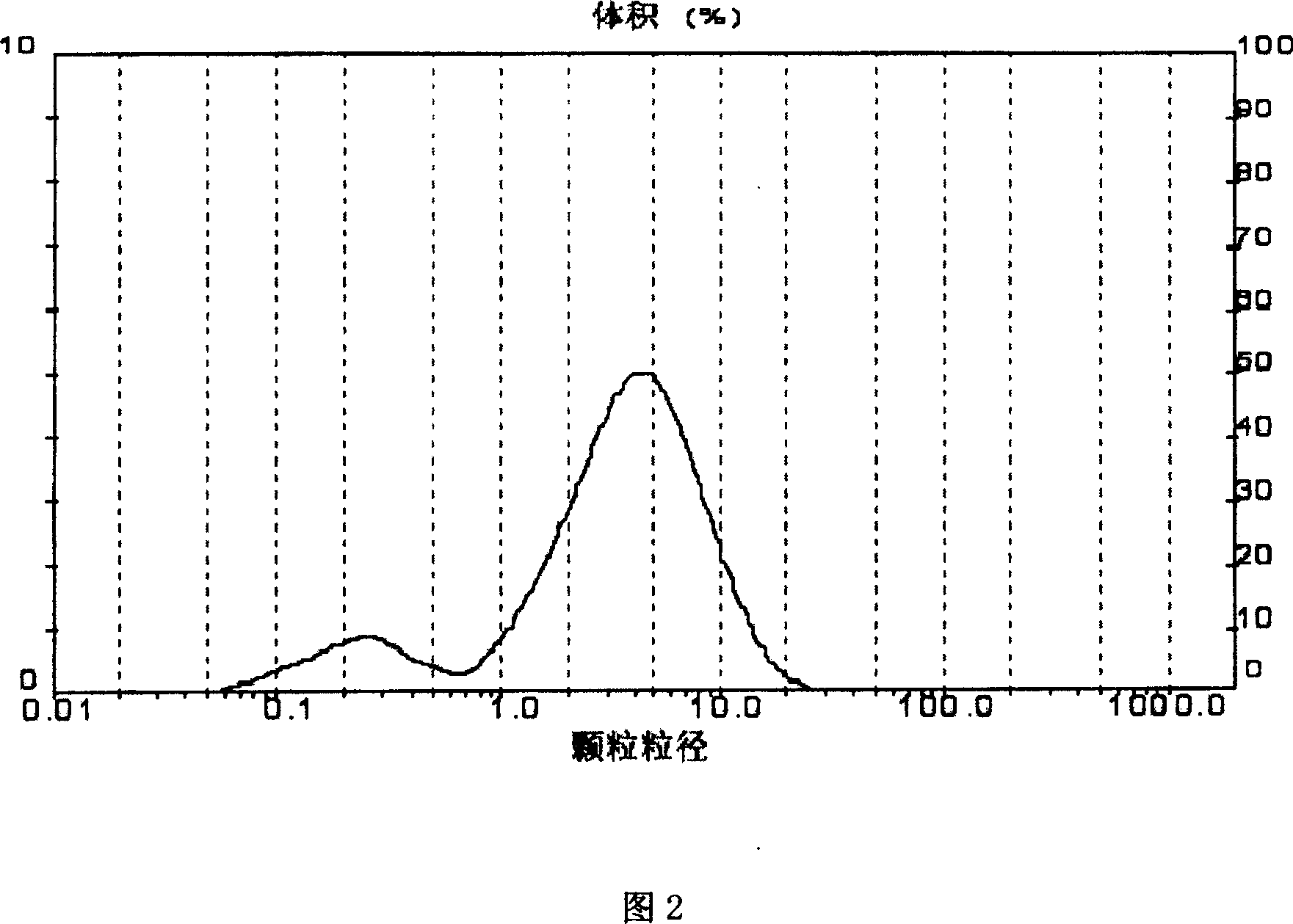

[0031] A) Take 100g of realgar, pick up impurities, coarsely pulverize, dry under the temperature condition of 60°C after preliminary water flying, and ultrafinely pulverize with jet mill for half an hour to obtain 85g of realgar superfine powder, set aside, the obtained particles are 50% of the particles The particle size is less than 4.18μm, the distribution is relatively concentrated, and the processing process can effectively avoid the generation of a large amount of heat to oxidize the realgar;

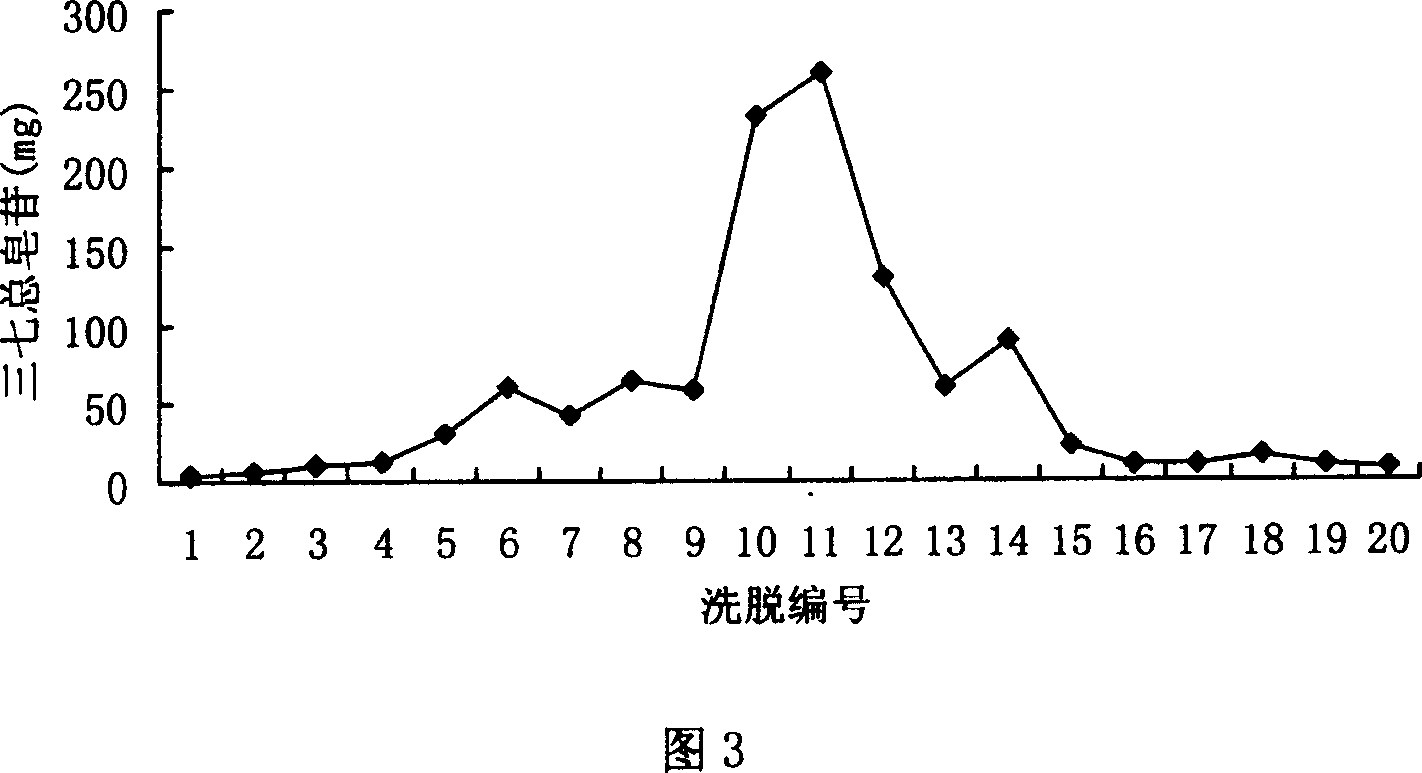

[0032] B) Take 200g of Panax notoginseng, crush it into a coarse powder, and extract twice with 70% ethanol under reflux, adding alcohol 8 times the weight of the medicinal material each time, extracting for 1.5 hours each time, combining the reflux liquid, and recovering the ethanol under reduced pressure until the drug content is 0.3 g·ml -1 , the extract was passed through the AB-8 macroporous adsorption resin column, washed with distilled water until the Molish reaction of th...

Embodiment 2

[0037] A) Take 50g of realgar, pick up impurities, coarsely pulverize, dry under the temperature condition of 40°C after preliminary water flying, and ultrafinely pulverize with a jet mill for half an hour to obtain 36g of realgar superfine powder, set aside, the obtained particles are 50% of the particles The particle size is less than 4.60μm, the distribution is relatively concentrated, and the processing process can effectively avoid the generation of a large amount of heat to oxidize the realgar;

[0038] B) Take 100g of Panax notoginseng, crush it into a coarse powder, and extract twice with 65% ethanol under reflux, each time adding alcohol to 7 times the weight of the medicinal material, extracting for 1.0 hour each time, combining the reflux liquid, and recovering the ethanol under reduced pressure until the drug content is 0.5 g·ml -1, the extract was passed through the AB-8 macroporous adsorption resin column, washed with distilled water until the Molish reaction of ...

Embodiment 3

[0043] A) Take 70g of realgar, pick up impurities, coarsely pulverize, dry under the temperature condition of 60°C after preliminary water flying, and ultrafinely pulverize with a jet mill for half an hour to obtain 45g of realgar superfine powder, set aside, the obtained particles are 50% of the particles The particle size is less than 4.42μm, the distribution is relatively concentrated, and the processing process can effectively avoid the generation of a large amount of heat to oxidize the realgar;

[0044] B) Take 120g of Panax notoginseng, crush it into a coarse powder, and extract twice with 75% ethanol under reflux, add 9 times of alcohol each time, extract for 2 hours each time, combine the reflux liquid, and recover the ethanol under reduced pressure until the drug content is 0.4g ·ml -1 , the extract was passed through the AB-8 macroporous adsorption resin column, washed with distilled water until the Molish reaction of the effluent was negative, then eluted with 55% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com