Equipment for blending light-wt. dry powder material

A powdery, light-weight technology that is applied to mixers, dissolvers, and mixers with rotating stirring devices. It can solve the problems of affecting the quality of slurry preparation, high proportion of solute consumption, and large amount of dust, so as to reduce batching failures. The probability of occurrence, the improvement of operational safety, and the effect of eliminating dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

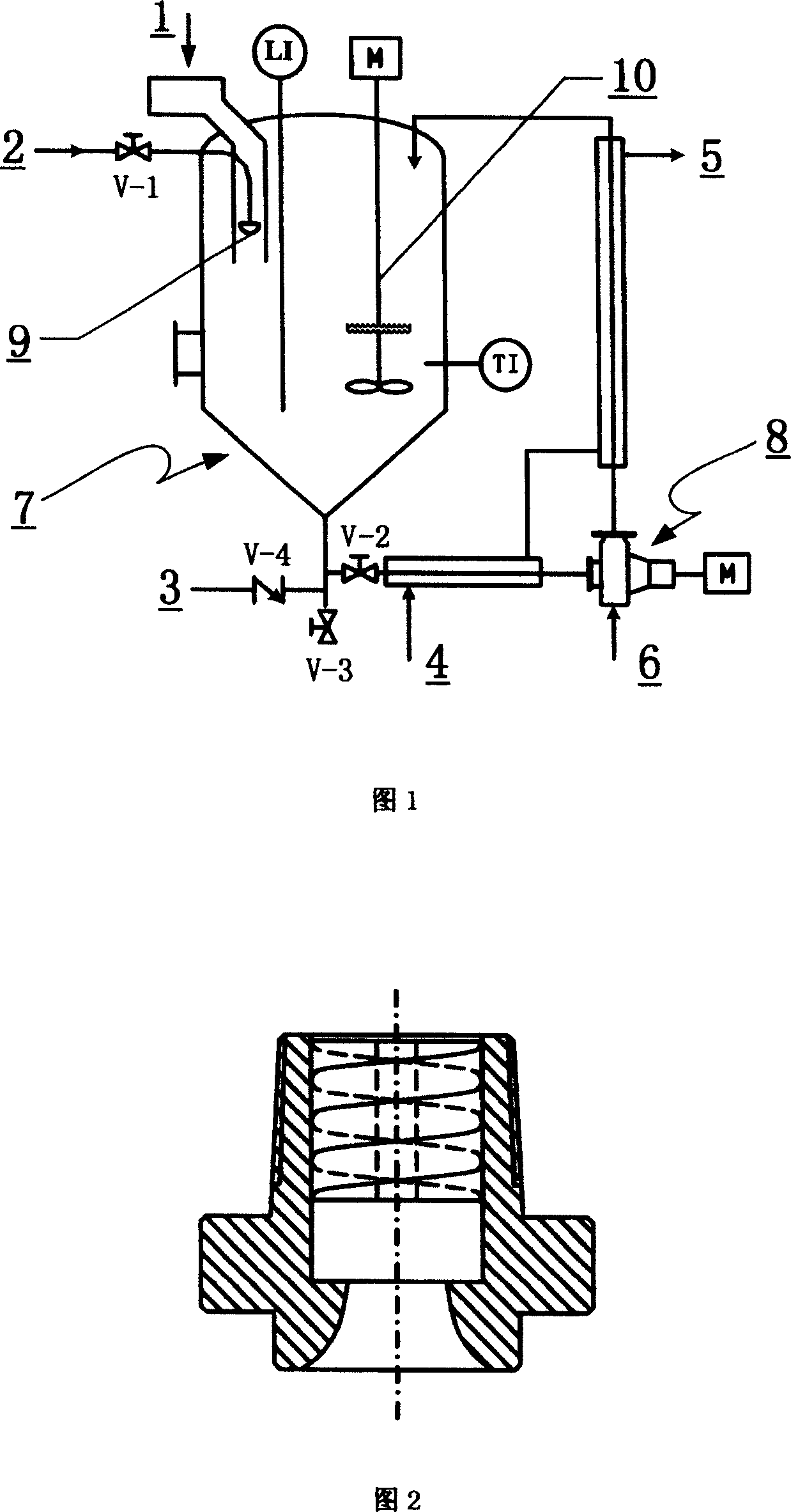

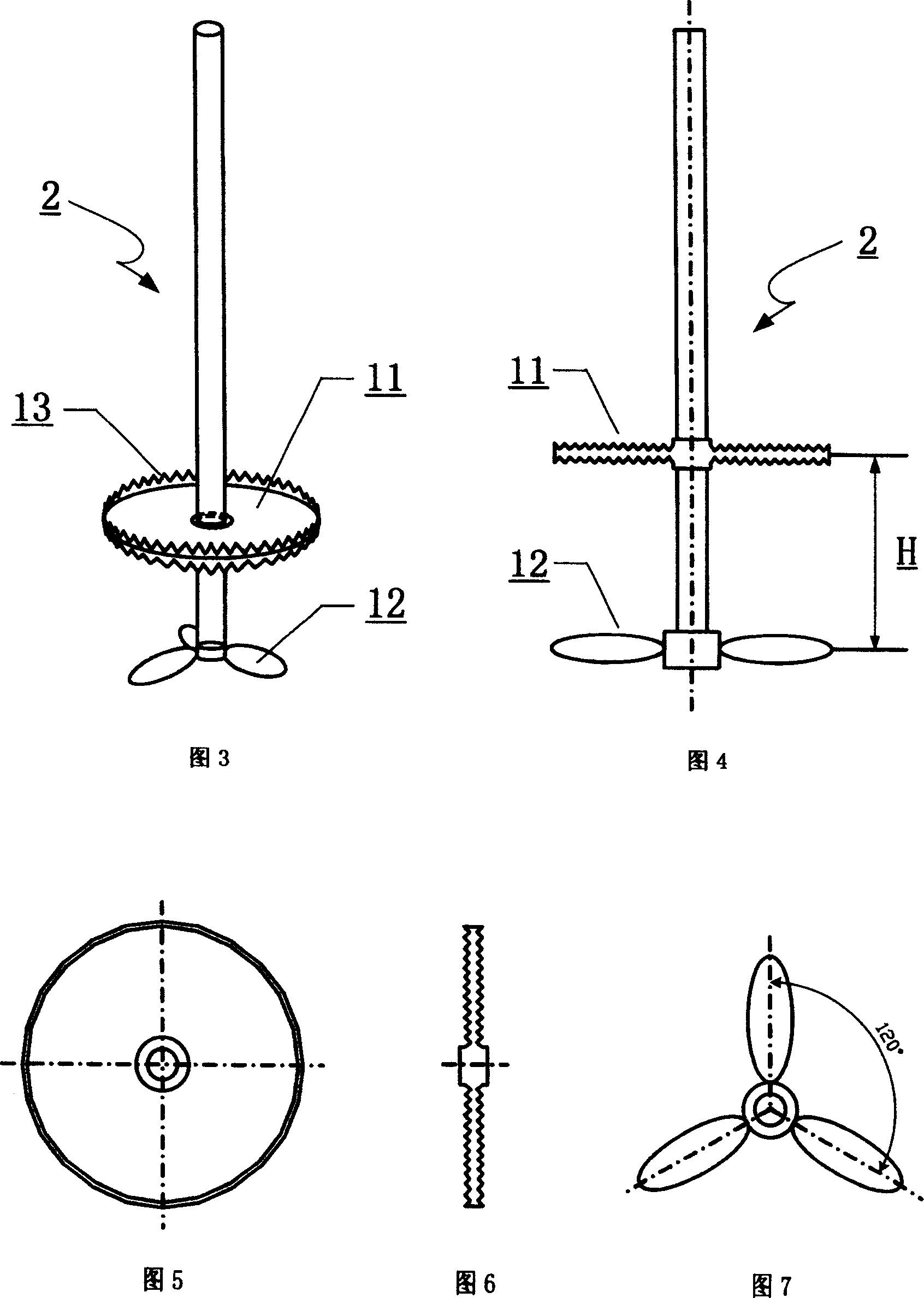

[0025] As shown in Figures 1 to 7, the light powdery dry material blending device of the present invention includes a blending tank 7 and a disperser 8, the light powdery dry material 1 is added from the solid feeding port at the top of the blending tank 7, and the solvent 2 passes through the valve V-1 feeds into the tank. The end of the solvent 2 feeding pipe is equipped with a nozzle 9, and the nozzle 9 is installed inside the feeding channel of the solid material. The inside of the mixing tank 7 is provided with an agitator 10, and the agitator 10 is equipped with double-layer paddles, the upper layer is a toothed disc type paddle 11, and the lower floor is a pusher type paddle 12 (Fig. 3, Fig. 4). The distribution of the teeth 13 on the toothed disc type paddle 11 is two circles, and the orientation of the teeth 13 is respectively upward and downward, forming two circles (Fig. 5, Fig. 6); Swept propulsion blades (Fig. 7). At the bottom of the blending tank 7, there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com