Inorganic composite nano intelligent repair agent, and its preparing method

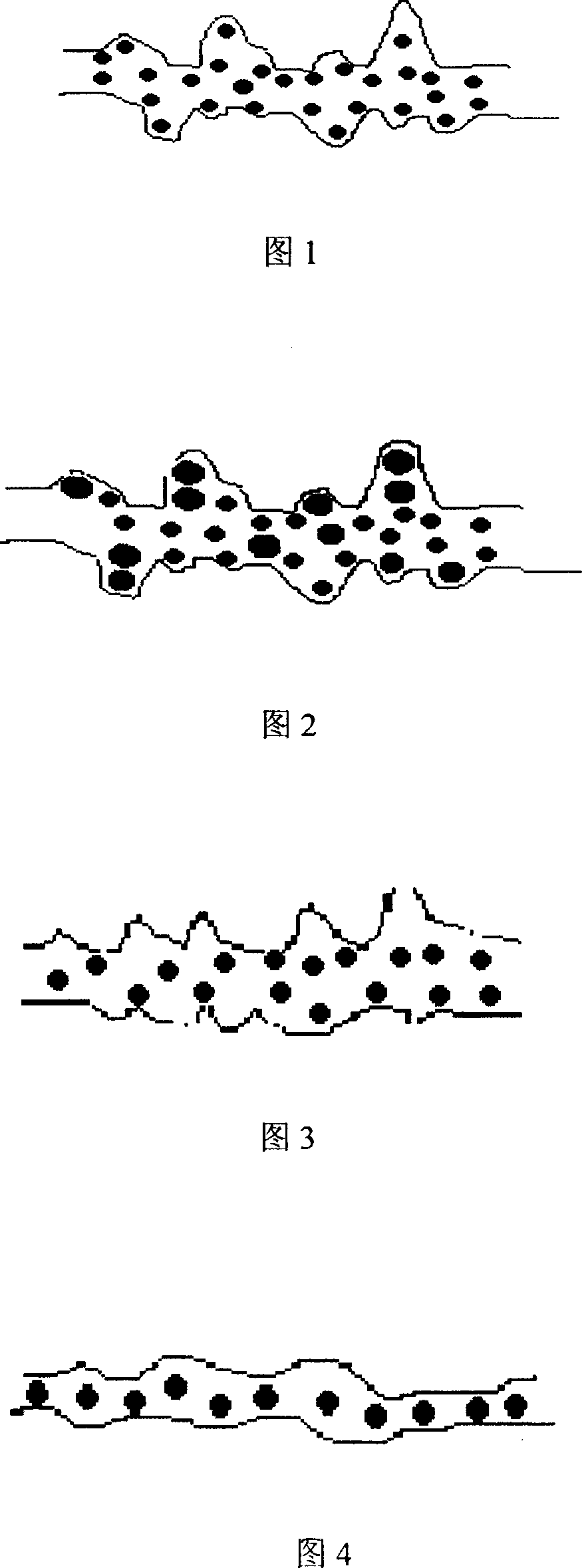

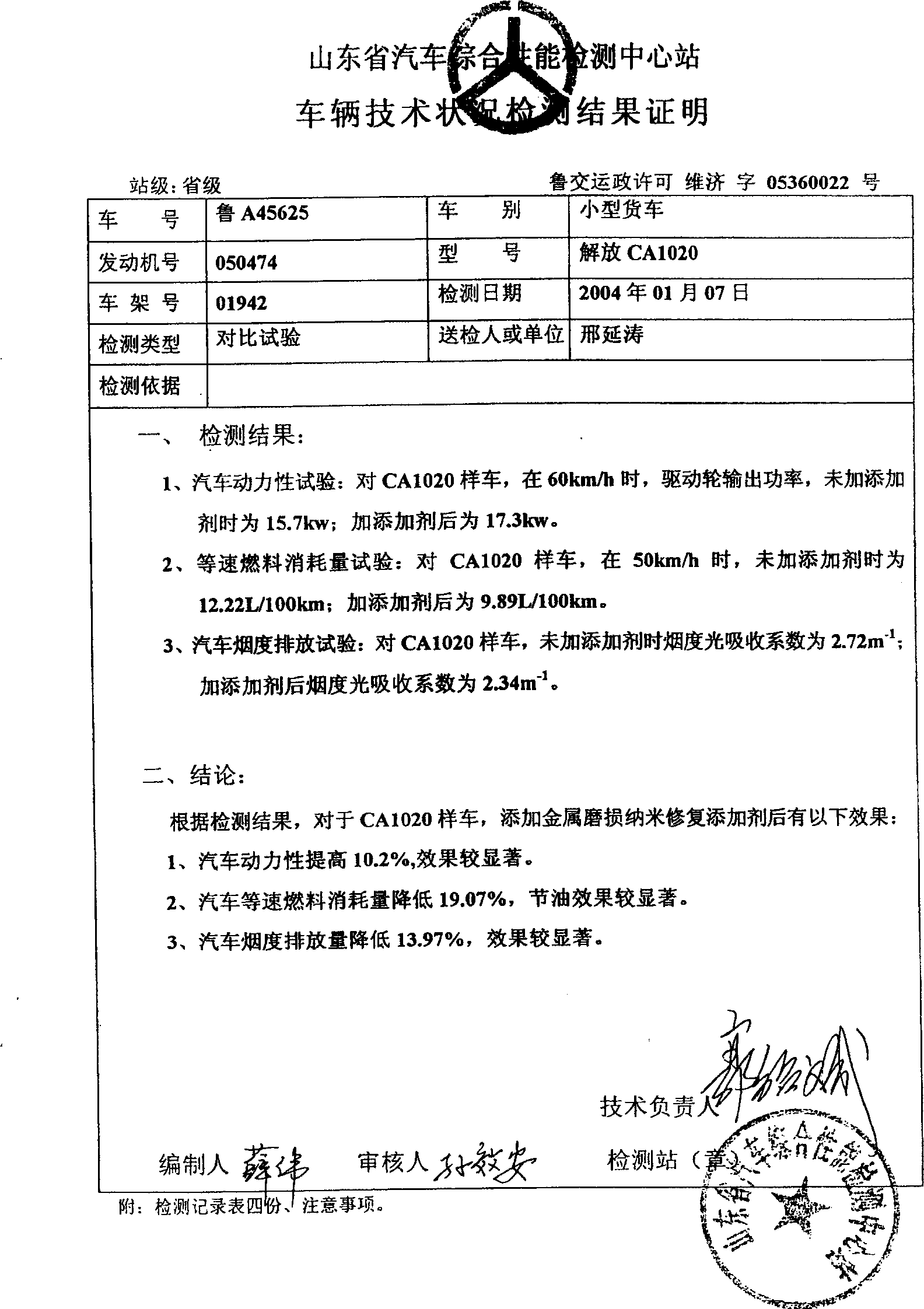

An intelligent repair, inorganic composite technology, applied in thickeners, lubricating compositions, petroleum industry, etc., can solve the problem that the surface roughness of the material is difficult to exceed 14, the design size cannot be maintained for a long time, and it is difficult to break through 900 ℃ Limit and other issues, to achieve the effect of anti-aging finish, improved finish, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.3kg of SiO 2 , 0.35kg of AL 2 o 3 , 0.35kg of MgO are pulverized into 20-micron fine powders with ordinary mechanical machines respectively; the above-mentioned fine powders are added to 500kg of lubricating oil, mixed uniformly, added in an ultrasonic pulverizer with ultrasonic waves, and ultrasonically pulverized to produce the Invented nano intelligent repair agent. The above-mentioned ultrasonic pulverizer adopts the ultrasonic pulverizer in Example 1 in Patent No. 200310105421. A total of 19 ultrasonic transmitters, the vibration frequency is 35KHz, and the total power is 1500W.

[0030] The data were measured by the Material Analysis Laboratory of the School of Materials Science and Engineering, Jinan University, and the data are shown in Table 1.

[0031] Table 1 Particle size measurement result table

[0032] project name

Embodiment 2

[0034] Weigh 0.2kg of SiO 2 , 0.25kg of AL 2 o 3 , 0.5kg of MgO are pulverized into 20-micron fine powders with ordinary mechanical machines respectively; the above-mentioned fine powders are added to 25kg of lubricating oil, mixed uniformly, added to an ultrasonic pulverizer with ultrasonic waves, and ultrasonically pulverized to produce the Invented nano intelligent repair agent. The above-mentioned ultrasonic pulverizer adopts the ultrasonic pulverizer in Example 1 in Patent No. 200310105421. A total of 19 ultrasonic transmitters, the vibration frequency is 25KHz, and the total power is 500W.

[0035] The data were measured by the material analysis laboratory of the School of Materials Science and Engineering, Jinan University, and the data are shown in Table 2.

[0036] Table 2 Particle size measurement result table

[0037] project name

Embodiment 3

[0039] Weigh 0.3kg of SiO 2 , 0.4kg of AL 2 o 3 , 0.45kg of MgO are pulverized into 20-micron fine powders with ordinary mechanical machines respectively; the above-mentioned fine powders are added to 100kg of lubricating oil, mixed evenly, added to an ultrasonic pulverizer with ultrasonic waves, and ultrasonically pulverized to produce the Invented nano intelligent repair agent. The above-mentioned ultrasonic pulverizer adopts the ultrasonic pulverizer in Example 1 in Patent No. 200310105421. A total of 19 ultrasonic transmitters, the vibration frequency is 45KHz, and the total power is 1000W.

[0040] The data were measured by the Material Analysis Laboratory of the School of Materials, Jinan University, and the data are shown in Table 3.

[0041] Table 3 Particle size measurement result table

[0042] project name

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com