System and method for bending a substantially rigid substrate

A substrate and bending technology, applied in the direction of circuit substrate materials, printed circuits connected with non-printed electrical components, printed circuits, etc., can solve problems such as increased fracture and splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

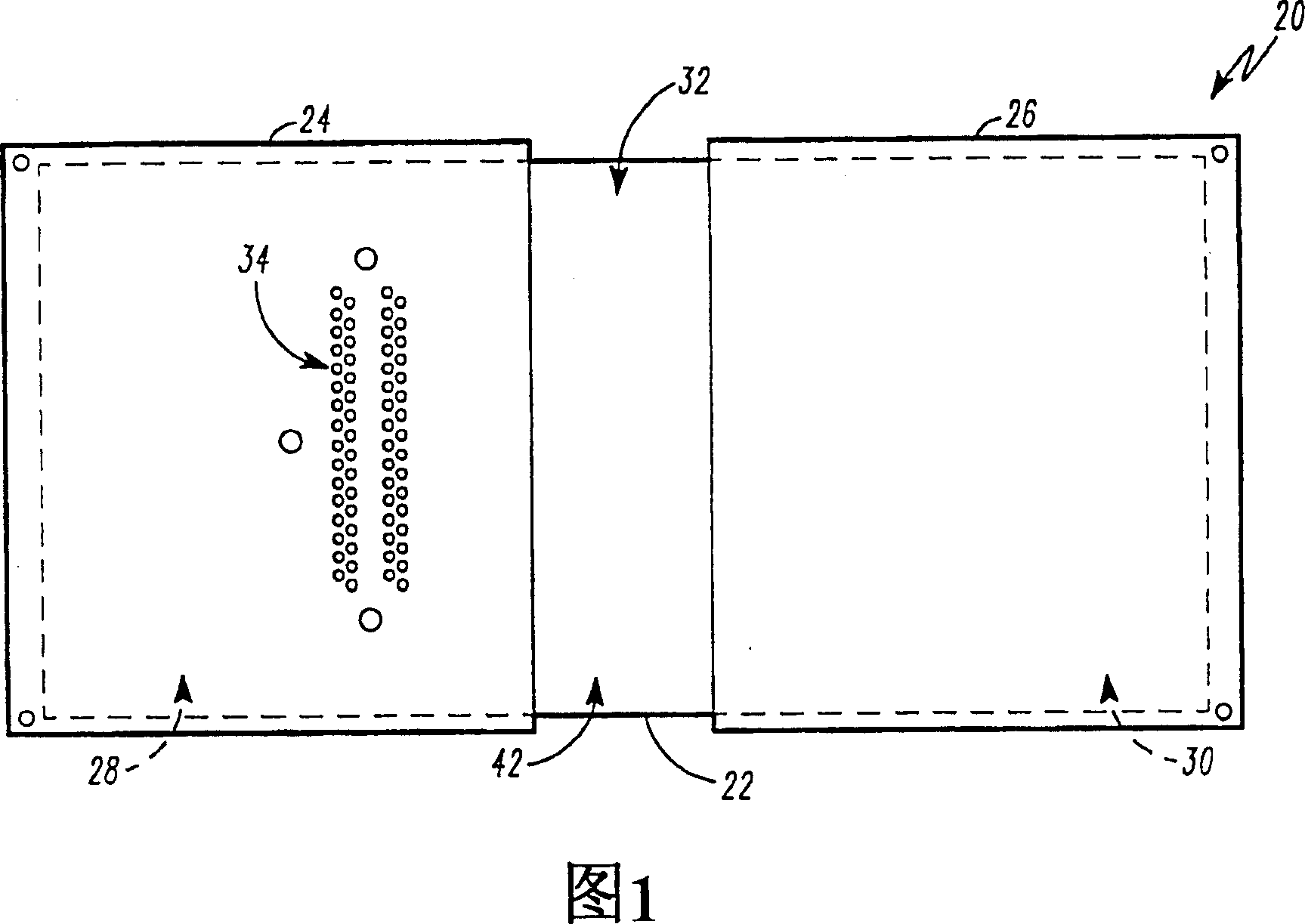

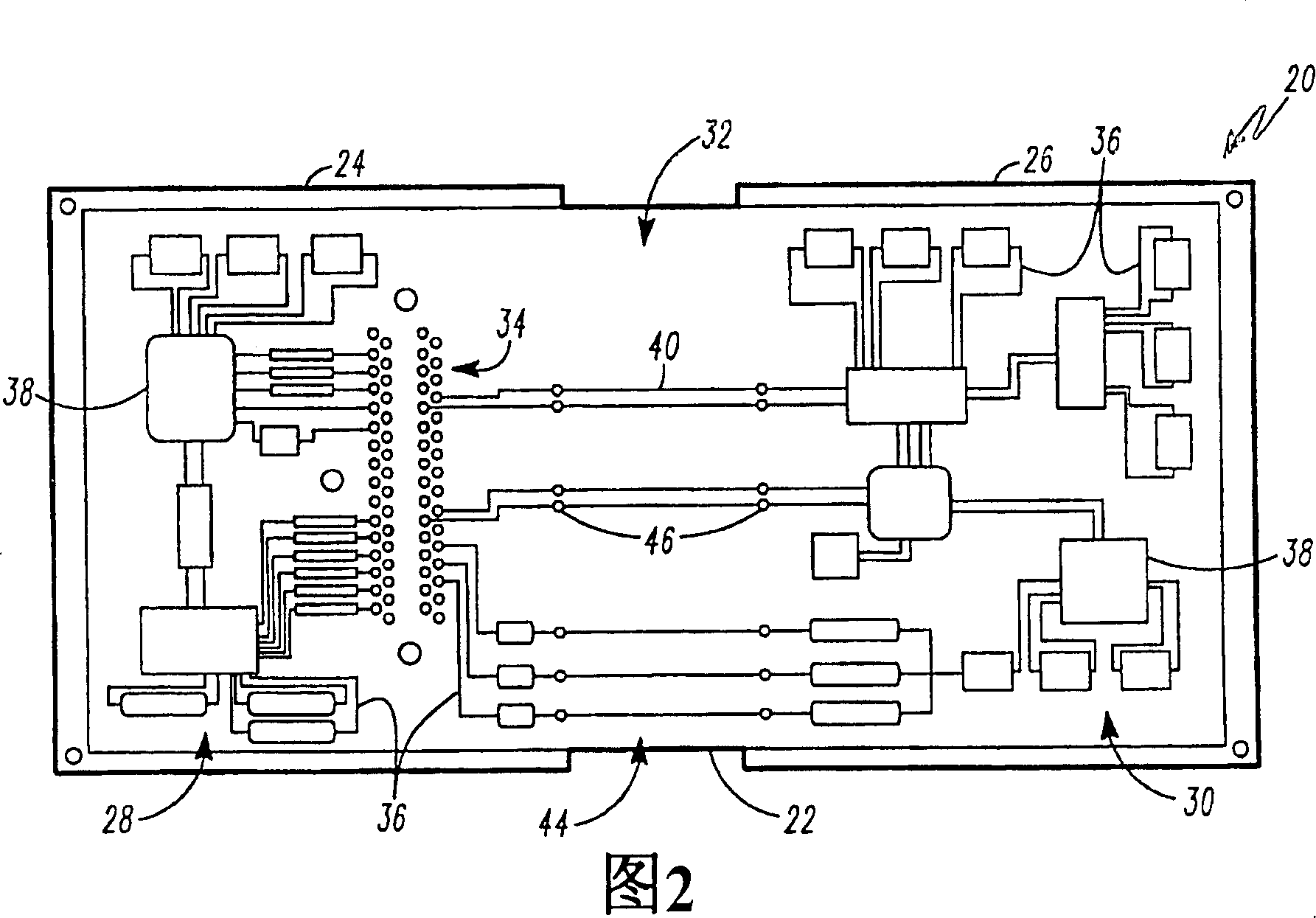

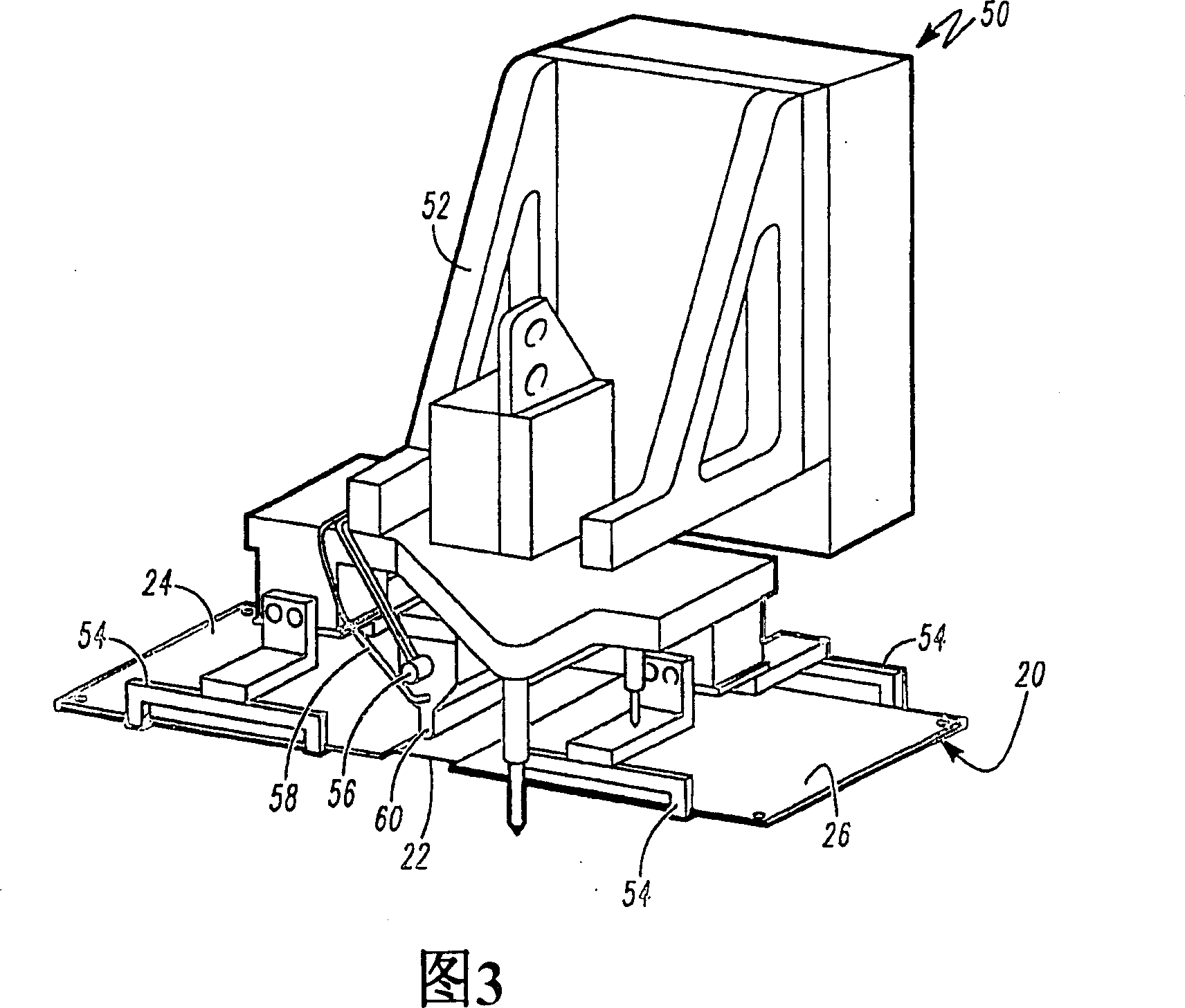

[0028] Referring now to the drawings, an example use of the apparatus and method will be explained in the context of an arrangement for an electronic control unit of a vehicle. Figures 1 and 2 show opposite sides of an example circuit board 20 located in an electronic control unit. In one embodiment, generally, the circuit board 20 has a substantially rigid substrate 22 , a first stiffener portion 24 and a second stiffener portion 26 . The substantially rigid substrate 22 has a first portion 28 and a second portion 30 interconnected by a bend 32 . The substantially rigid substrate 22 may be made of FR4 or other relatively rigid organic substrates. FR4 is a material with at least one layer of glass texture impregnated with epoxy resin. Other types of glass epoxy and polyimide are also commercially available. The substantially rigid substrate 22 may also be formed from multiple layers of substrate material laminated together, making the substrate more rigid or brittle. Altho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com