Novel mulberry tea and its producing method

A production method and technology of mulberry tea, applied in medical preparations containing active ingredients, tea substitutes, pharmaceutical formulas, etc., can solve the problems of low-grade products, unacceptable, lack of material selection and processing technology, etc., and achieve light green soup color Clear, refreshing and strong aroma, fresh and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

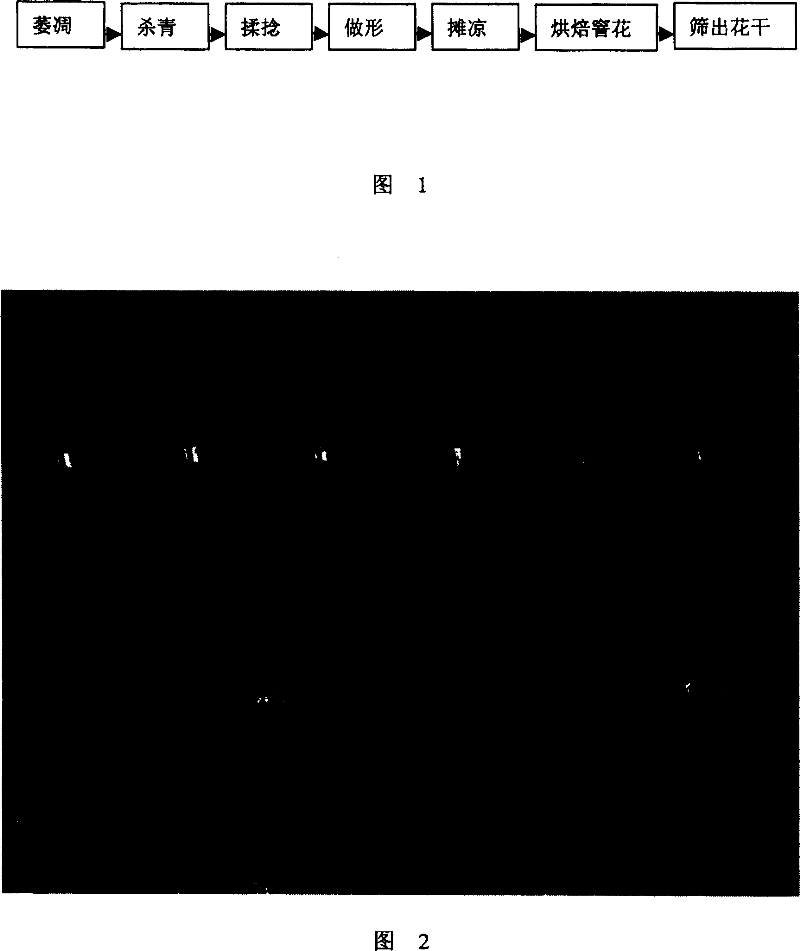

[0022] The process of making mulberry tea of the present invention is:

[0023] 1. Raw materials: according to the quality requirements of high-grade green tea, choose mulberry buds with long buds and leaves, fat and young, and the picking standard is one bud, one leaf and two leaves.

[0024] 2. Withering: Fresh mulberry buds wither slightly and naturally indoors after harvesting. Spread the mulberry buds on the bamboo mat with a leaf thickness of 2-3cm for 1 hour. When the temperature is high and the water content of the fresh buds is heavy, the withering time will be prolonged, otherwise the time will be shortened, so that the fresh leaves will lose water by 10% to 15%. It also has a certain degree of softness.

[0025] 3. Finishing: Use green tea finishing equipment: high-temperature finishing with a drum fixing machine. Cylinder temperature 160 ℃, first high and then low. The 30-type roller degreening machine throws 30-50g of leaves every 2-3s, and the time for buds ...

Embodiment 2

[0031] The process of making mulberry tea of the present invention is:

[0032] 1. Raw materials: according to the quality requirements of high-grade green tea, choose mulberry buds with long buds and leaves, fat and young, and the picking standard is one bud, one leaf and two leaves.

[0033] 2. Withering: Fresh mulberry buds wither slightly and naturally indoors after harvesting. Spread the mulberry buds on the bamboo mat, the thickness of the spread leaves is 2-3cm, and the time is 3 hours. When the temperature is high and the water content of the fresh buds is heavy, the withering time will be prolonged, otherwise the time will be shortened, so that the fresh leaves will lose 10% to 15%. It also has a certain degree of softness.

[0034] 3. Finishing: Use green tea finishing equipment: electric frying pan, high temperature finishing. The temperature of the pot is 190°C, first high and then low. It takes 5 to 7 minutes to manually fix the leaves in a frying pan, throw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com