High-speed multi-stage charging system and method for self-adaptive tractive dynamic battery

An adaptive tracking and power battery technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as battery overcharge and battery undercharge, and achieve the effect of overcoming damage and eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

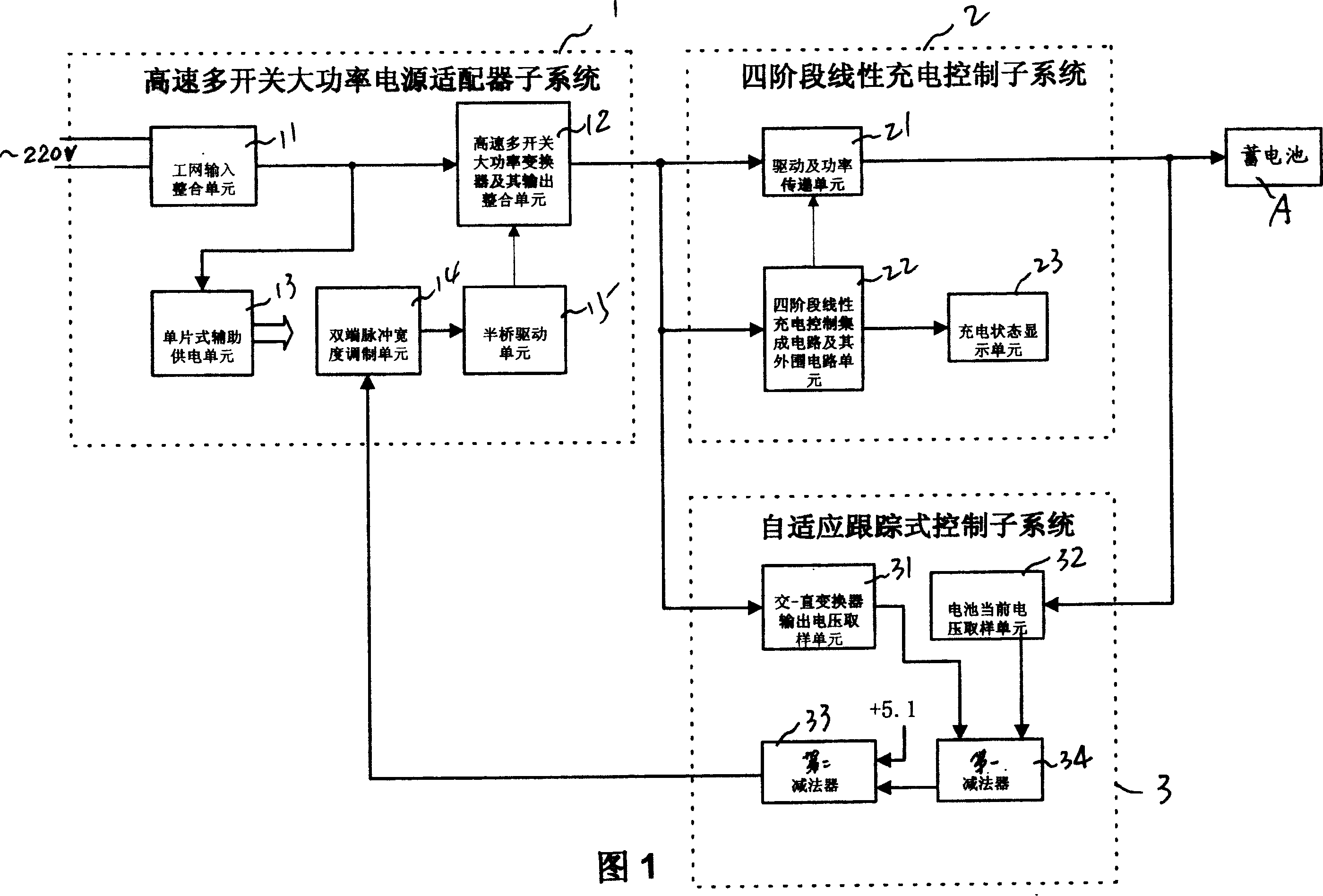

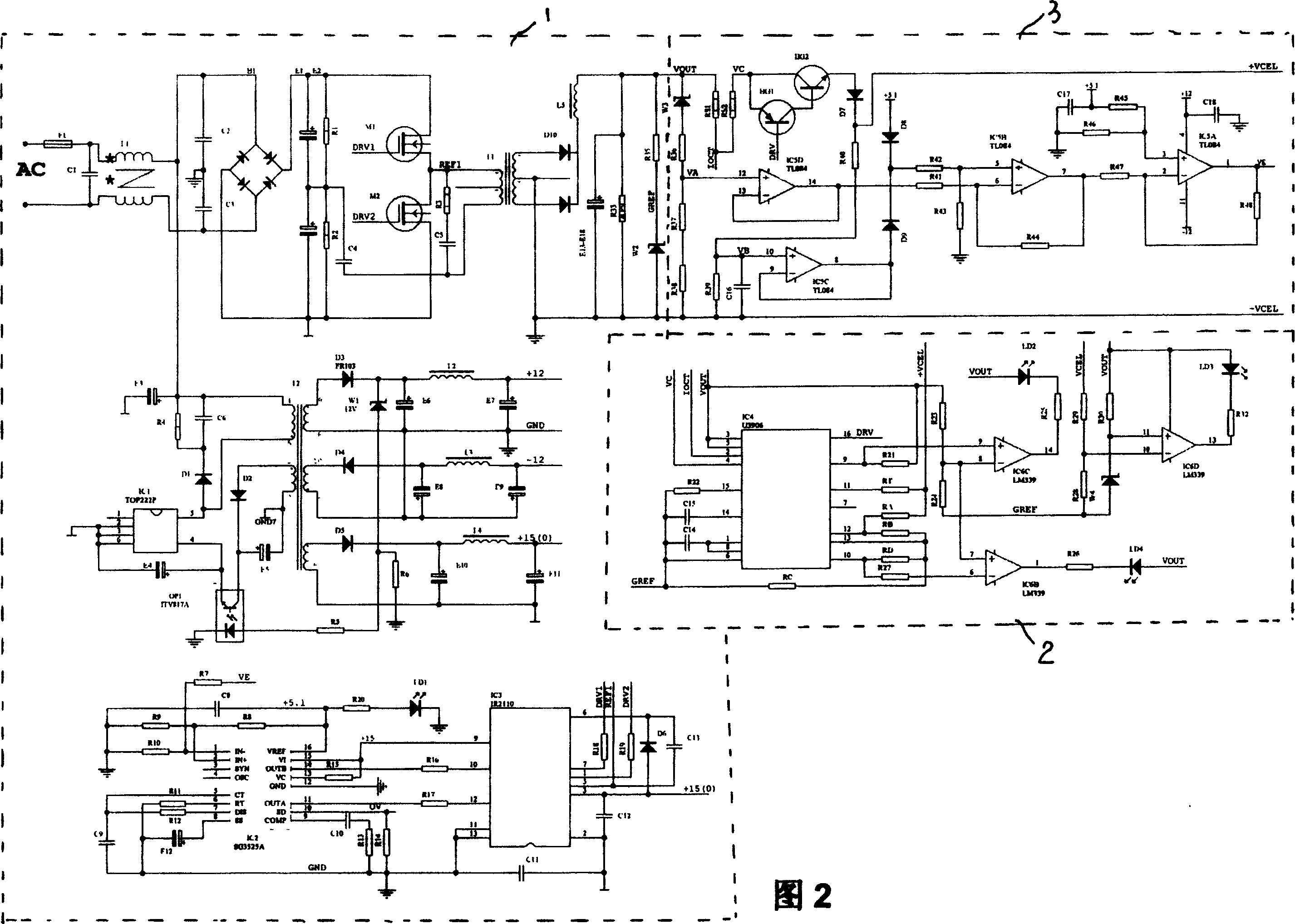

[0037] Please refer to attached picture 1. The technical solution for realizing the present invention is: an adaptive tracking type power battery multi-stage high-speed charging system, including a high-speed multi-switch high-power power adapter subsystem 1, a four-stage linear charging control subsystem 2, and an adaptive tracking type control subsystem 3. The high-speed multi-switch high-power power adapter subsystem 1 is used to complete the high-frequency high-power AC-DC conversion and provide the corresponding working power for each system of the present invention; the high-speed multi-switch high-power power adapter subsystem The input terminal of 1 is connected to the input AC power supply, and its output terminal is respectively connected to the input terminals of the four-stage linear charging control subsystem 2 and the adaptive tracking control subsystem 3; the four-stage linear charging control subsystem The output end of 2 is connected with battery A, and feeds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com