Loose type coning control method

A control method and winding technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems that the control technology requirements are not particularly strict, the control method is difficult to achieve, and the quality of subsequent processes is affected. The effect of moderate technical requirements, good social benefits, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

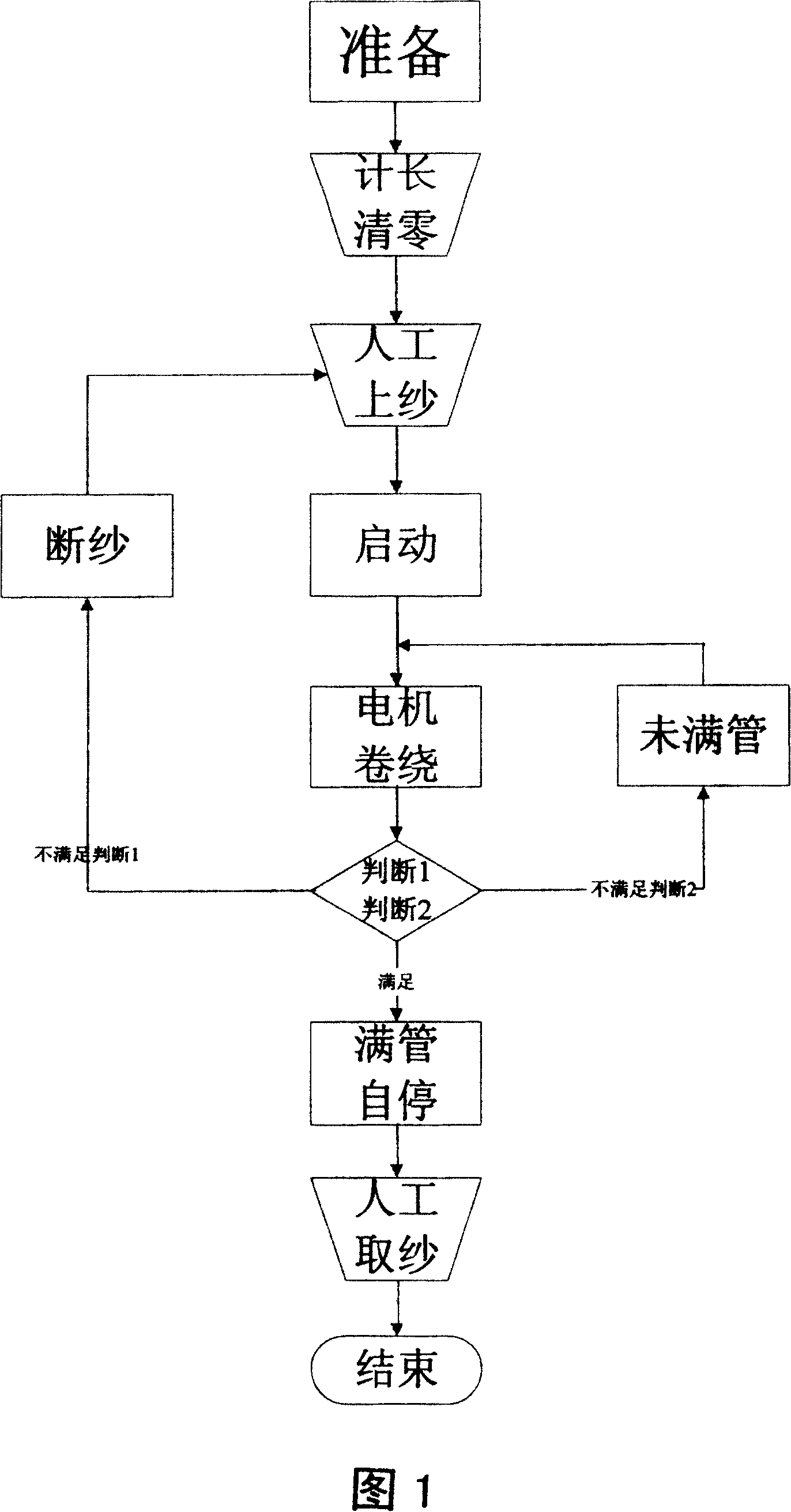

[0008] Referring to Figures 1 and 2, the loose winding control method includes the following steps:

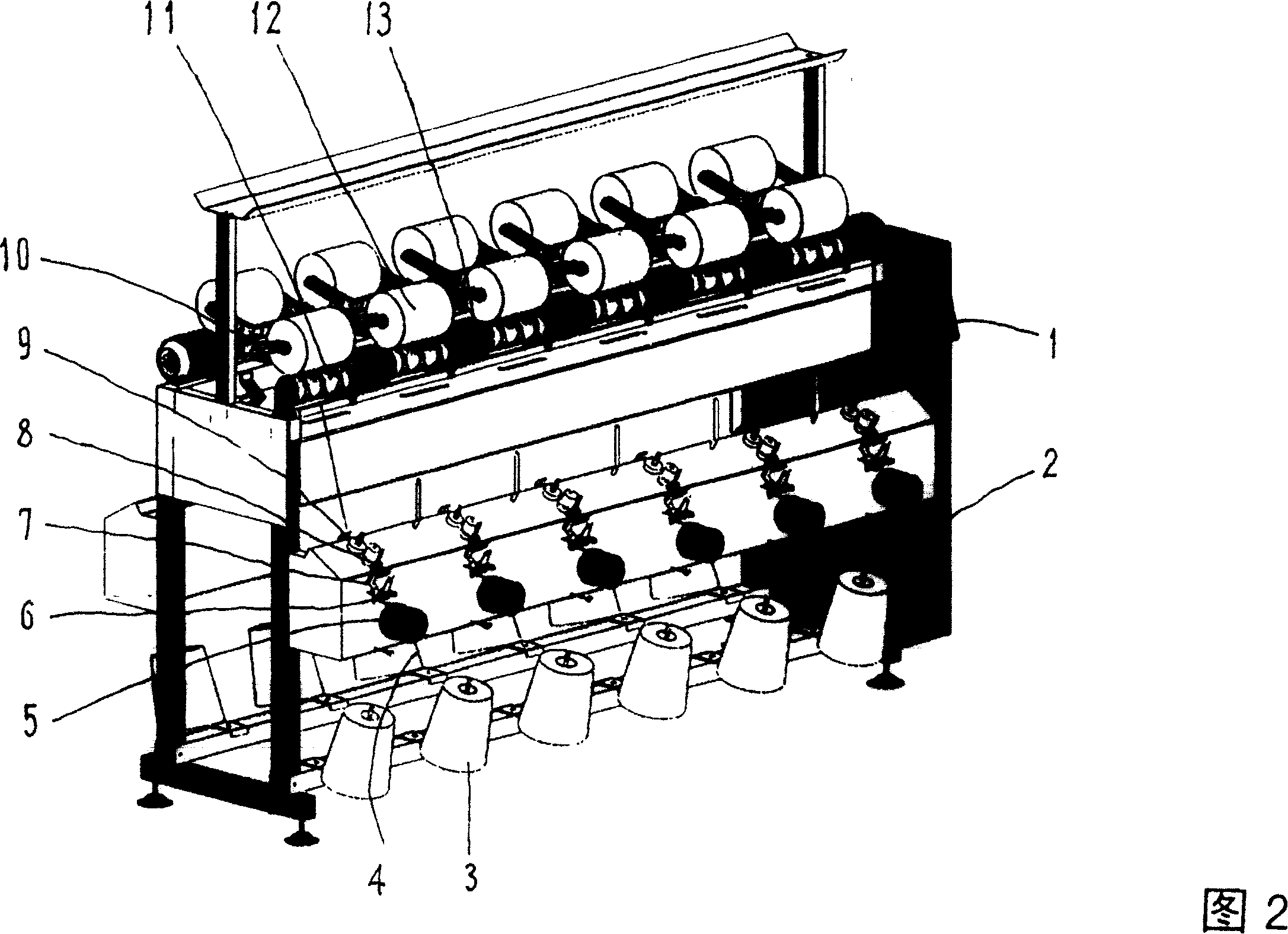

[0009] 1. Preparation——The preparation work includes turning on the power supply and initial setting and adjustment. The key parameters of the loose winding set on the touch screen 1 are: fixed length (set length value), appropriate anti-stacking parameters (frequency conversion Motor swing frequency amplitude, variable frequency motor swing frequency cycle), winding speed; put down the creel 10, adjust the spring force of the support rod; start the creel 10 traverse device, and the creel 10 micro traverse; the preparation work also includes the complete machine Monitoring and production calculation, the basis of preparation work is recipe parameters, production accumulation, setting and storage of monitoring data.

[0010] 2. Clearing the length of the counting - after the preparation work is completed, the operation is cleared on the working spindle position, so as to accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com