Continuous extraction apparatus for mineral bacteria leachate

An extraction device and leachate technology, which is applied in the extraction field of laboratory copper ore bacterial leachate, can solve the problems of non-continuous operation, low extraction rate, and inability to expand the experimental scale, etc., to achieve convenient control, high extraction efficiency, and save extraction agent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

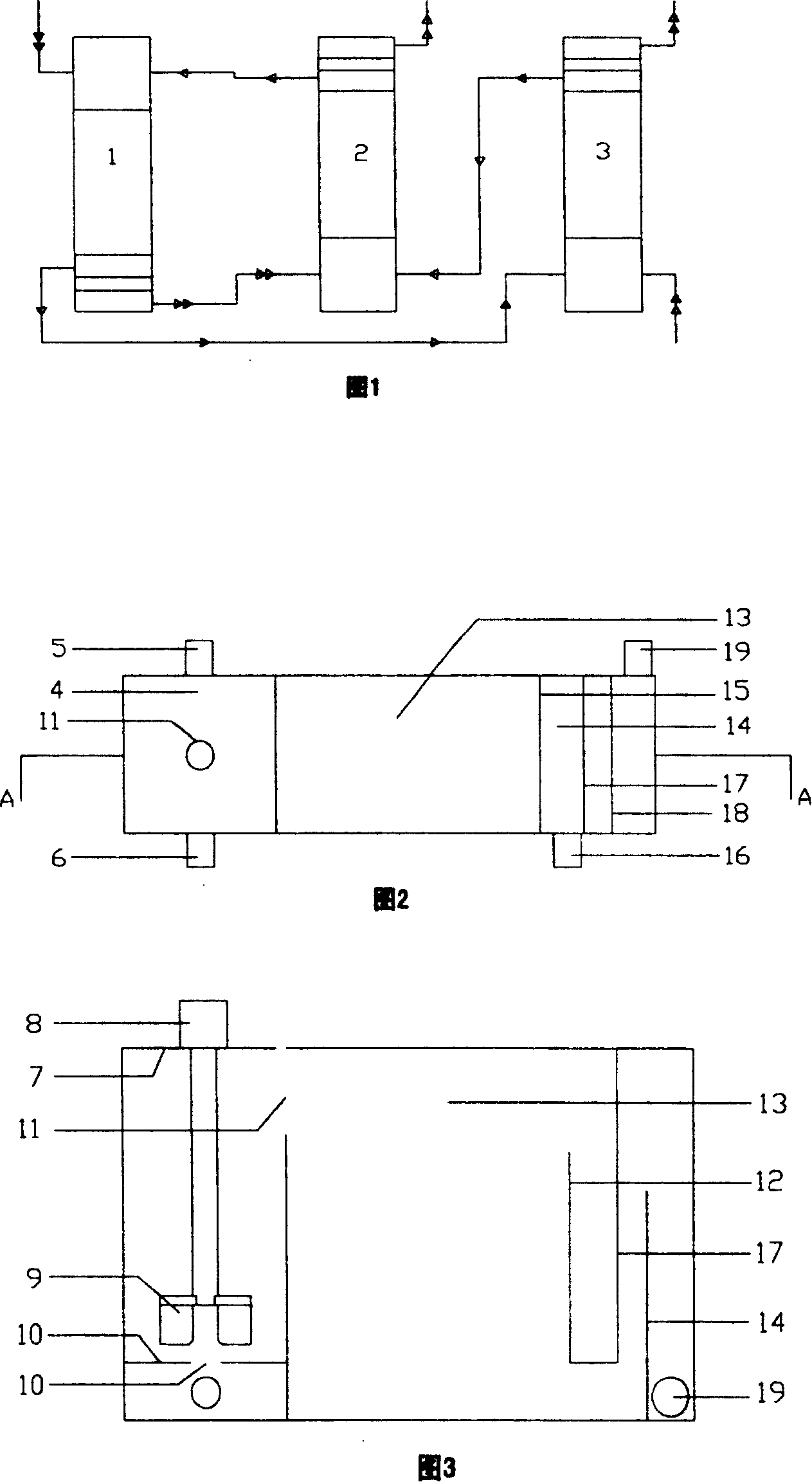

[0011] The device of the present invention is used to carry out extraction experiments on the circulating leaching liquid of a copper ore bacterial heap leaching test in a certain mine in my country. Concentrations of various components of the feed liquid are (g / L): Cu 1.12, Fe 0.74, Zn 3.53, pH 2.22. The extractant concentration is 5%, the diluent is sulfonated kerosene, and the stripping agent is 180g / L H 2 SO 4 solution. Other reaction conditions are: mixing time 4min, ratio (O / A) 2:3, equilibrium pH 2.5. The final extraction rate of copper reaches more than 98%. The extraction process is as follows:

[0012] The device is composed of three extraction tanks, and adopts the principle of combining countercurrent extraction and back extraction. The leachate is extracted into the loaded organic phase through the primary extraction tank 1 and the secondary extraction tank 2, while the extractant is extracted by the secondary extraction tank. Tank 2 enters, and after flowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com