Zinc-manganese battery

A zinc-manganese battery and battery negative electrode technology, which is applied in the field of environment-friendly zinc-manganese batteries, can solve problems such as environmental pollution, waste of metal zinc resources, uneven thickness, etc., and achieve great economic significance, save metal zinc, and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure and preparation method of the zinc-manganese battery provided by the present invention will be further described in detail below with reference to the accompanying drawings.

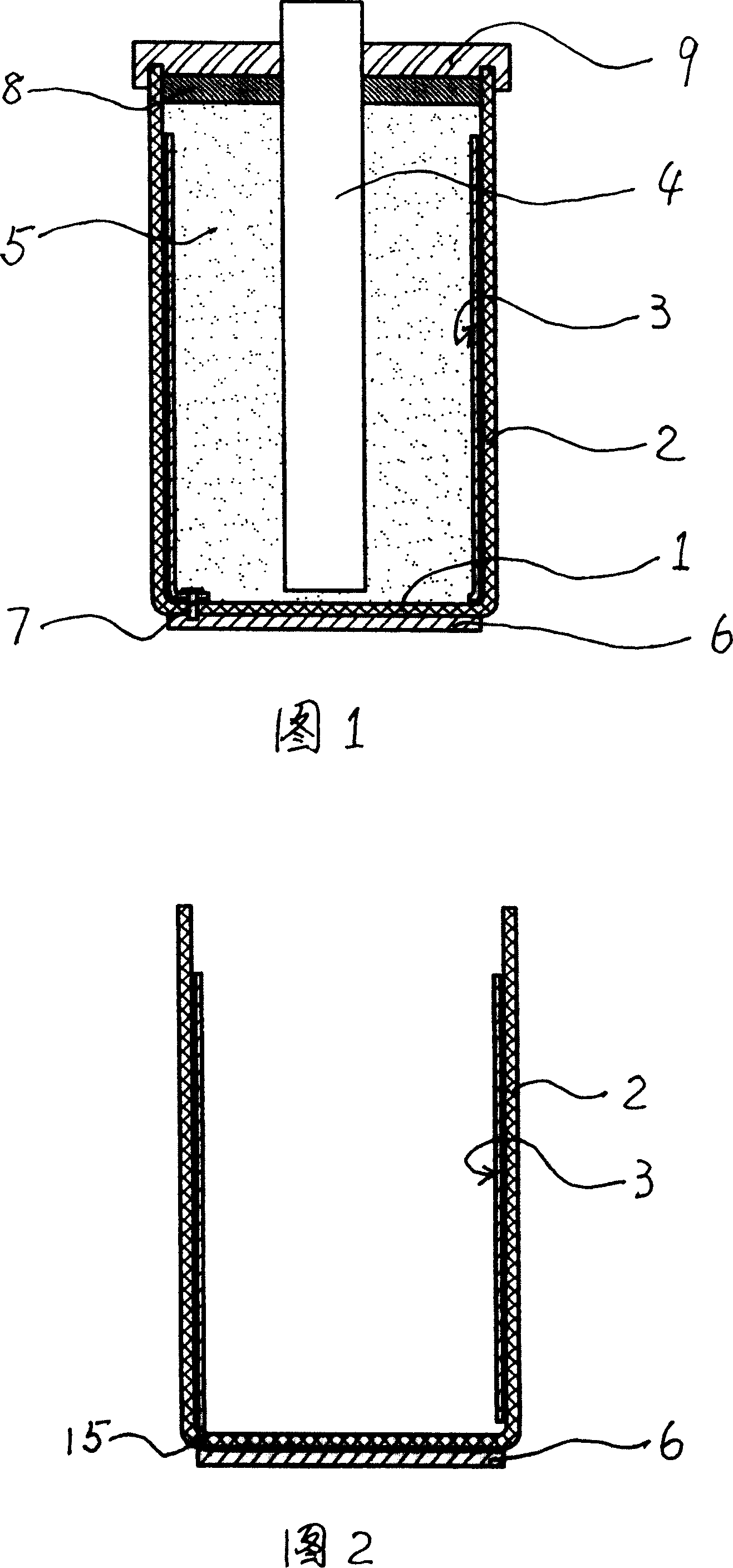

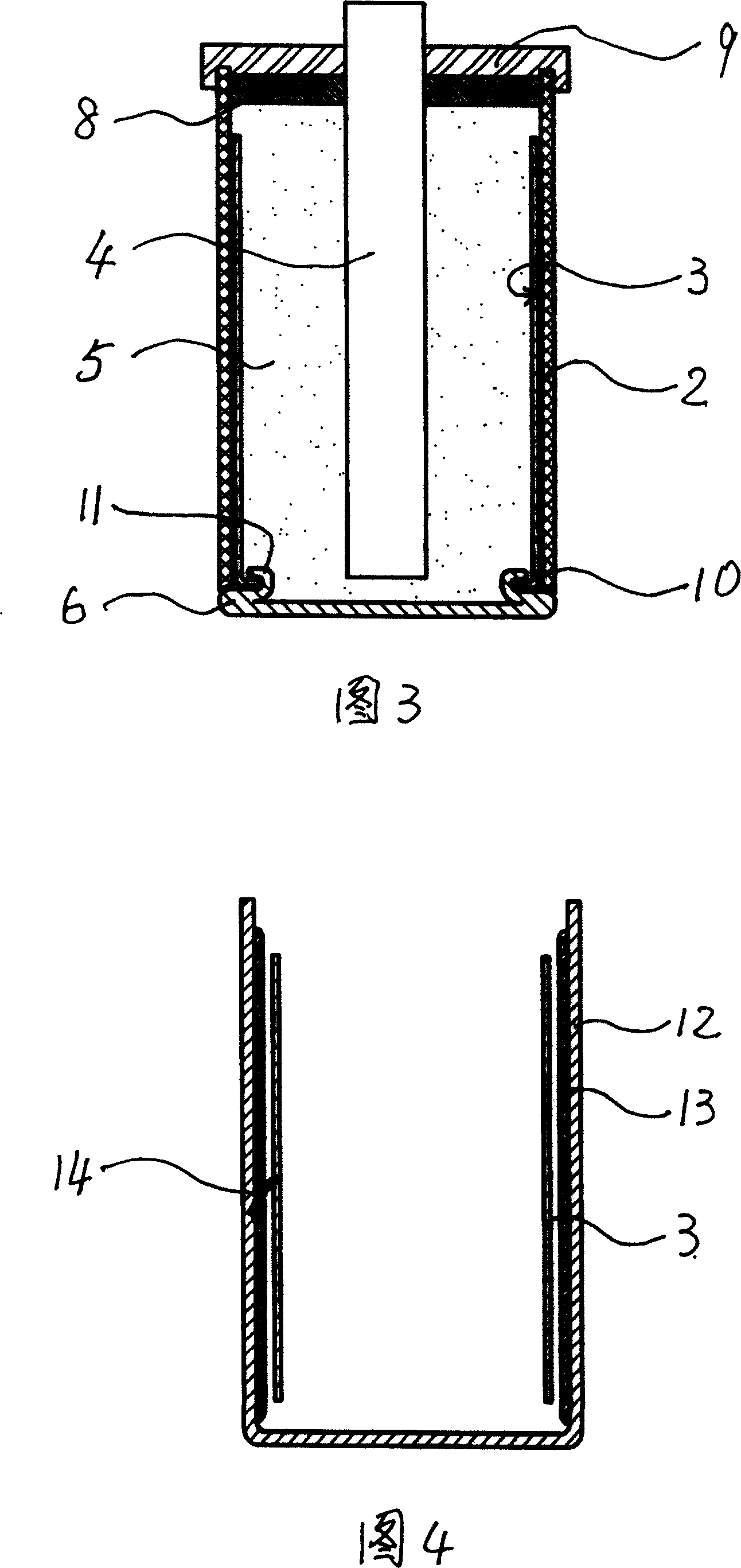

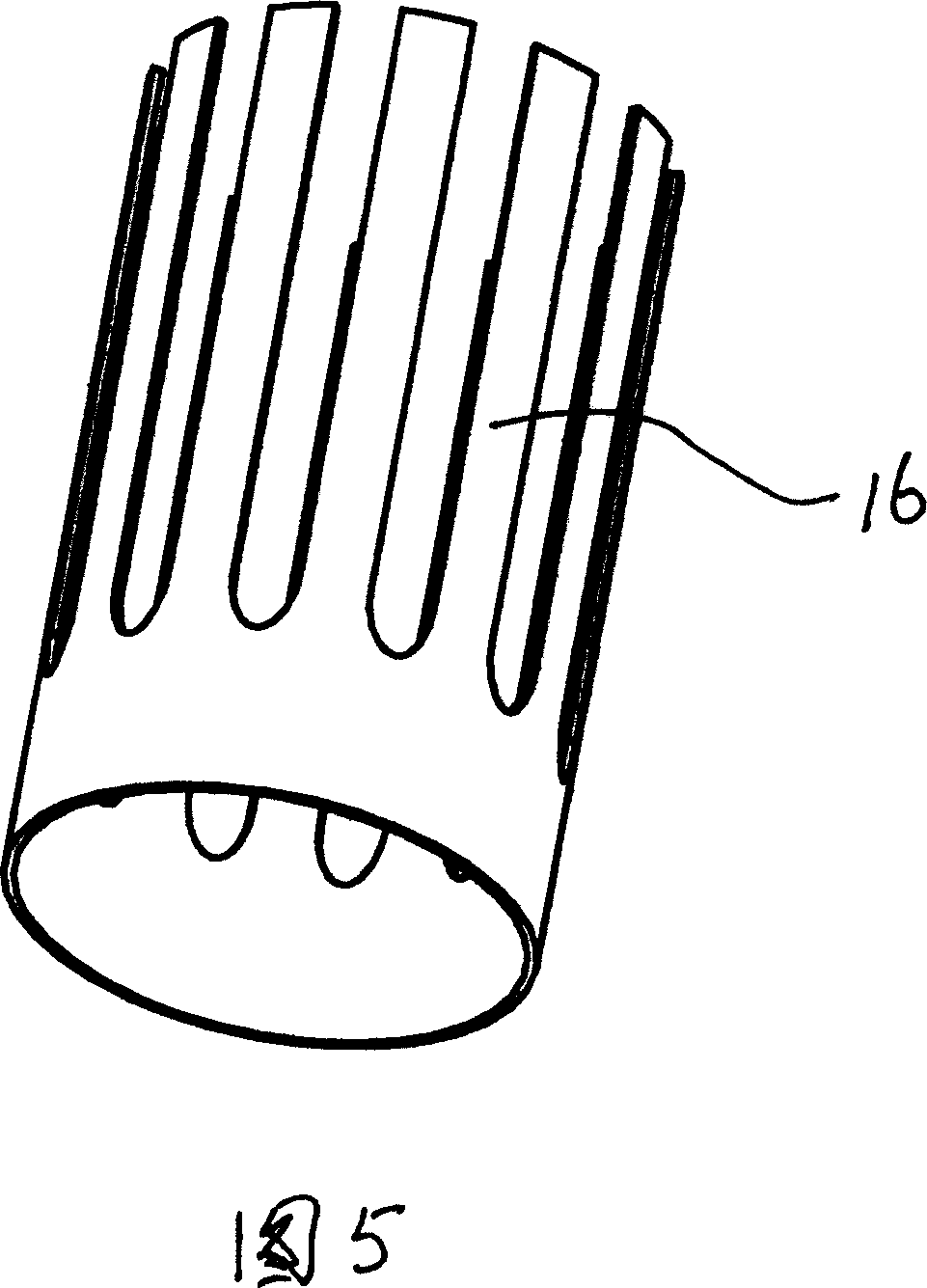

[0018] Figure 1 is a schematic diagram of the structure of the zinc-manganese battery provided by the present invention. The structure of the zinc-manganese battery includes: a barrel-shaped shell composed of a barrel bottom 1 and a barrel wall 2 as an integral structure, in the barrel-shaped shell On the wall is attached (or fixed and bonded with the inner wall by an adhesive) a ring-shaped zinc cylinder 3 made of metallic zinc material as the battery's negative electrode active material, and a carbon rod 4 as a battery power outlet is arranged in the middle, as The manganese dioxide mixture 5 that chemically reacts with the ring-shaped zinc cylinder is filled in the barrel-shaped shell; a false bottom metal sheet 6 as the battery electrode is fixed on the outer bottom of the barrel-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com