Robot arm with specimen edge gripping end effector

A technology of end effectors and test pieces, applied in the direction of manipulators, mechanical equipment, chucks, etc., can solve problems such as wafer processing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

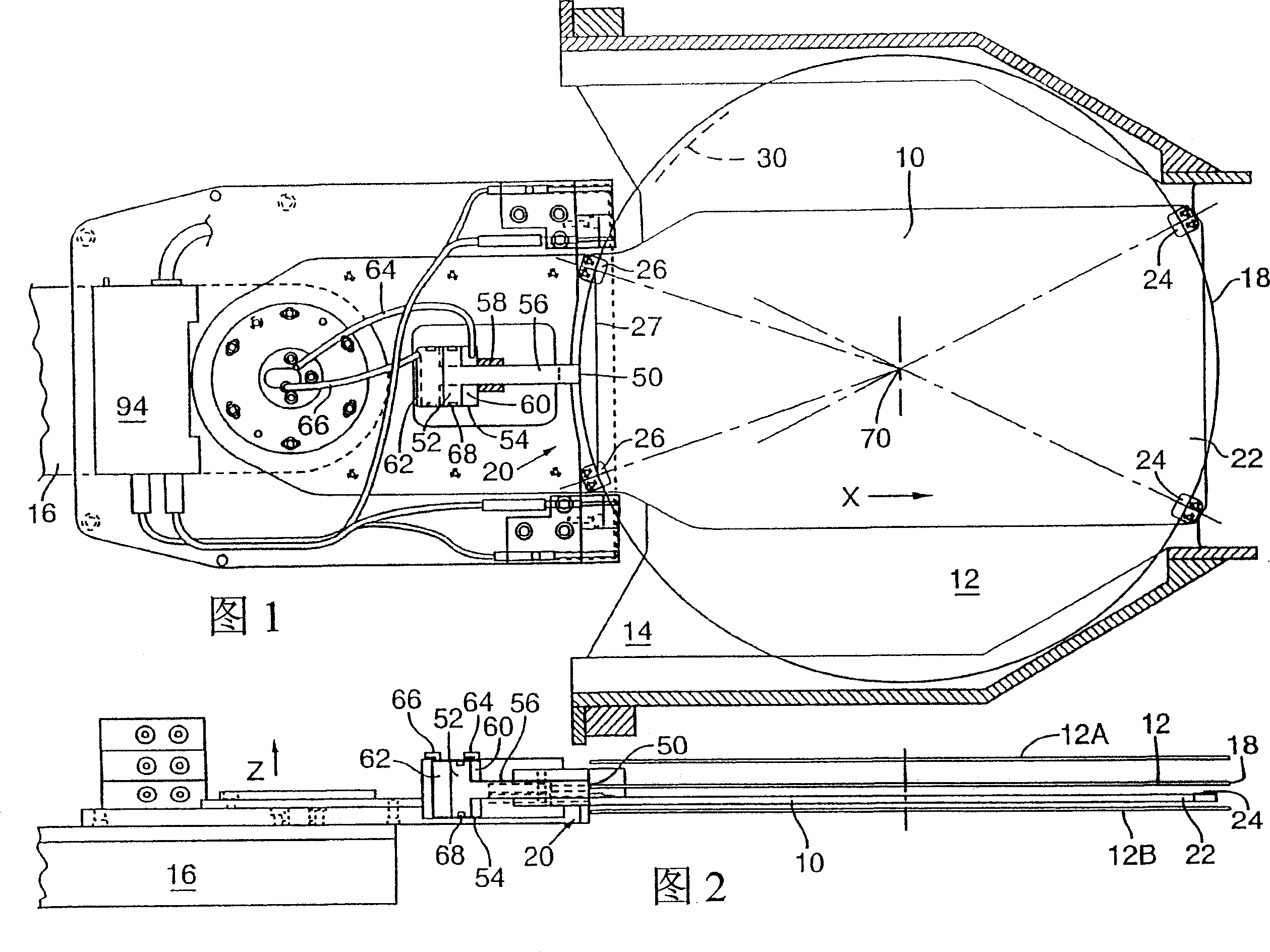

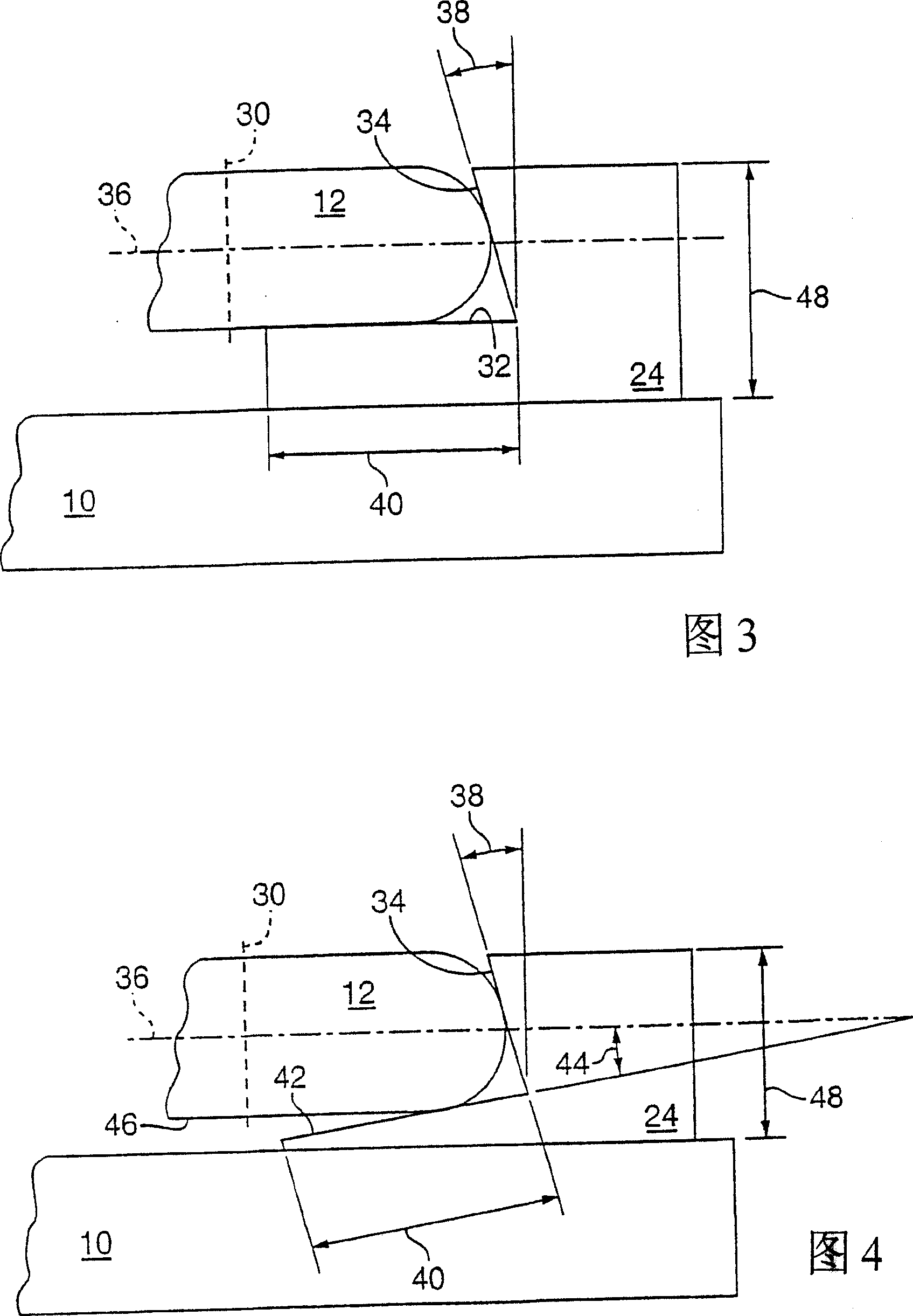

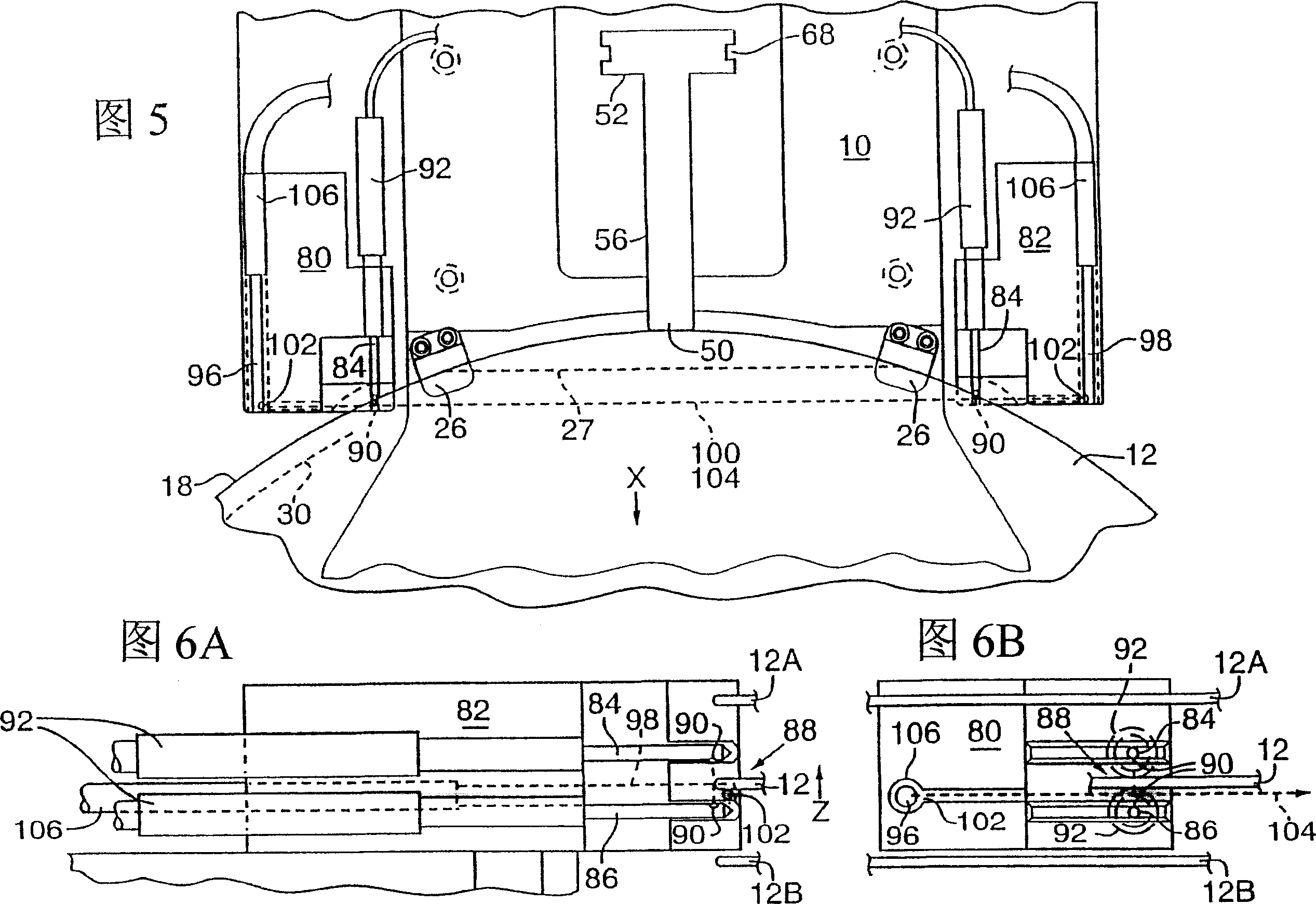

[0034] 1 and 2 show a spatula-shaped end effector 10 of a first example embodiment of the present invention, which can be used to return a semiconductor wafer, such as a wafer 12 (shown transparent to show the underlying structure), back to a wafer cassette 14 or from a wafer Take it out of box 14. End effector 10 is adapted to receive and securely hold wafer 12 and transfer it to cassette 14 or remove it for processing. End effector 10 shown in FIG. 2 is particularly suitable for removing and replacing closely spaced wafers stacked in wafer cassette 14, such as wafers 12, 12A and 12B. Wafers with a diameter of less than 150 mm are usually spaced at a pitch of 4.76 mm (3 / 16 inch); wafers with a diameter of 200 mm are usually spaced at a pitch of 6.35 mm (1 / 4 inch); wafers with a diameter of 300 mm are usually spaced at a pitch of 10 mm (0.394 inch).

[0035] End effector 10 is operably connected to manipulator 16 (only a portion of which is shown) which can be programmed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com