Fuel pump of compact structure for use in high torque

A fuel pump and fuel technology, applied in the directions of liquid fuel feeder, magnetic circuit shape/pattern/structure, winding conductor shape/pattern/structure, etc., can solve problems such as torque reduction, magnetic flux reduction, etc. The effect of corrosion, reducing inductance, and reducing the number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

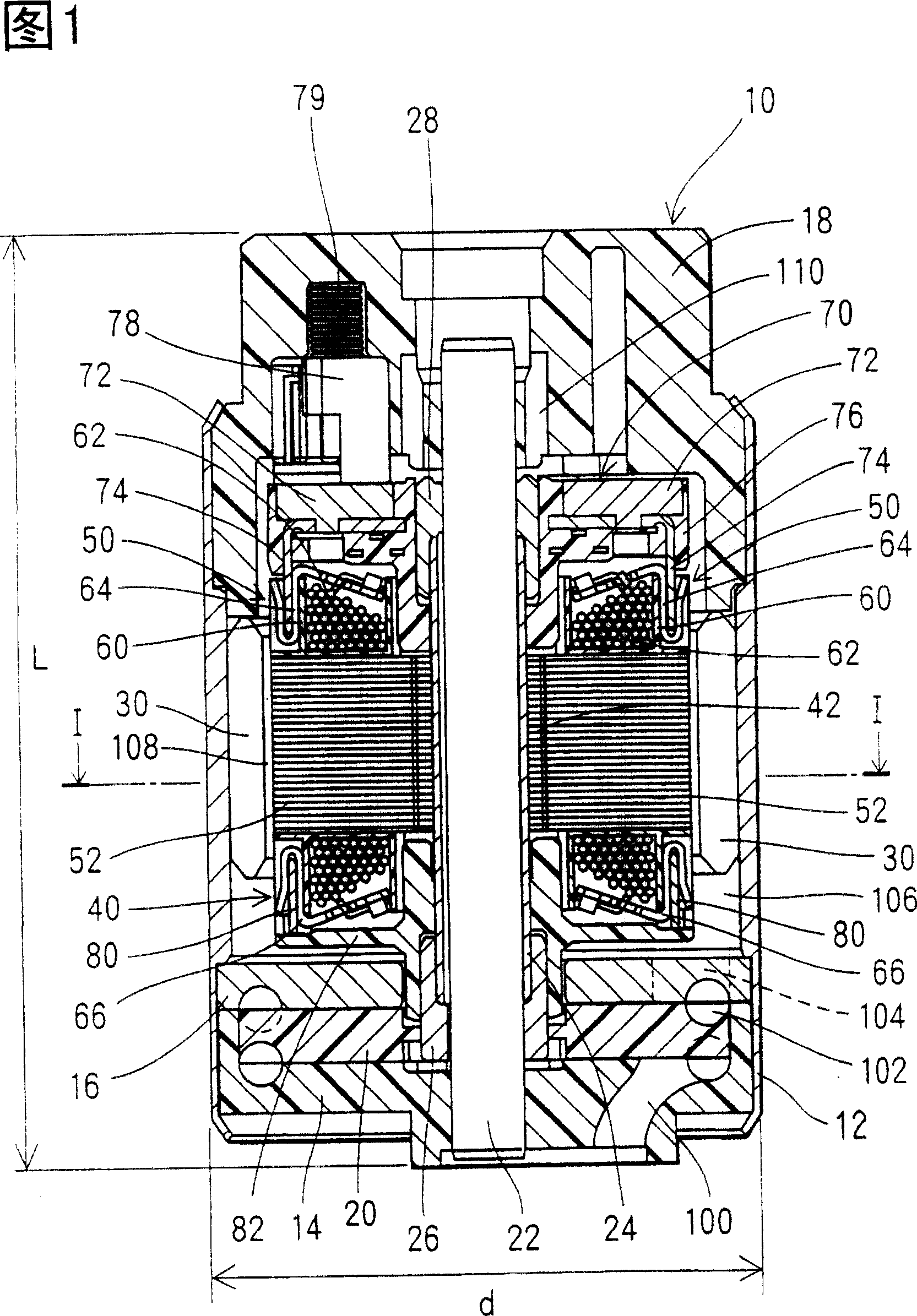

[0032] The fuel pump 10 shown in FIG. 1 is a tank pump. The fuel tank pump is installed, for example, in a fuel tank of a vehicle. A forged end cap 14 on the suction side and a forged end cap 18 on the discharge side are fixed in the housing 12 .

[0033] A pump cover 16 is supported by the suction side cover 14 and the housing 12 . A C-shaped pump passage 102 is formed between the suction side end cover 14 and the pump cover 16 . The suction side cover 14 and the pump cover 16 support an impeller 20 which is used as a rotating means for generating suction force.

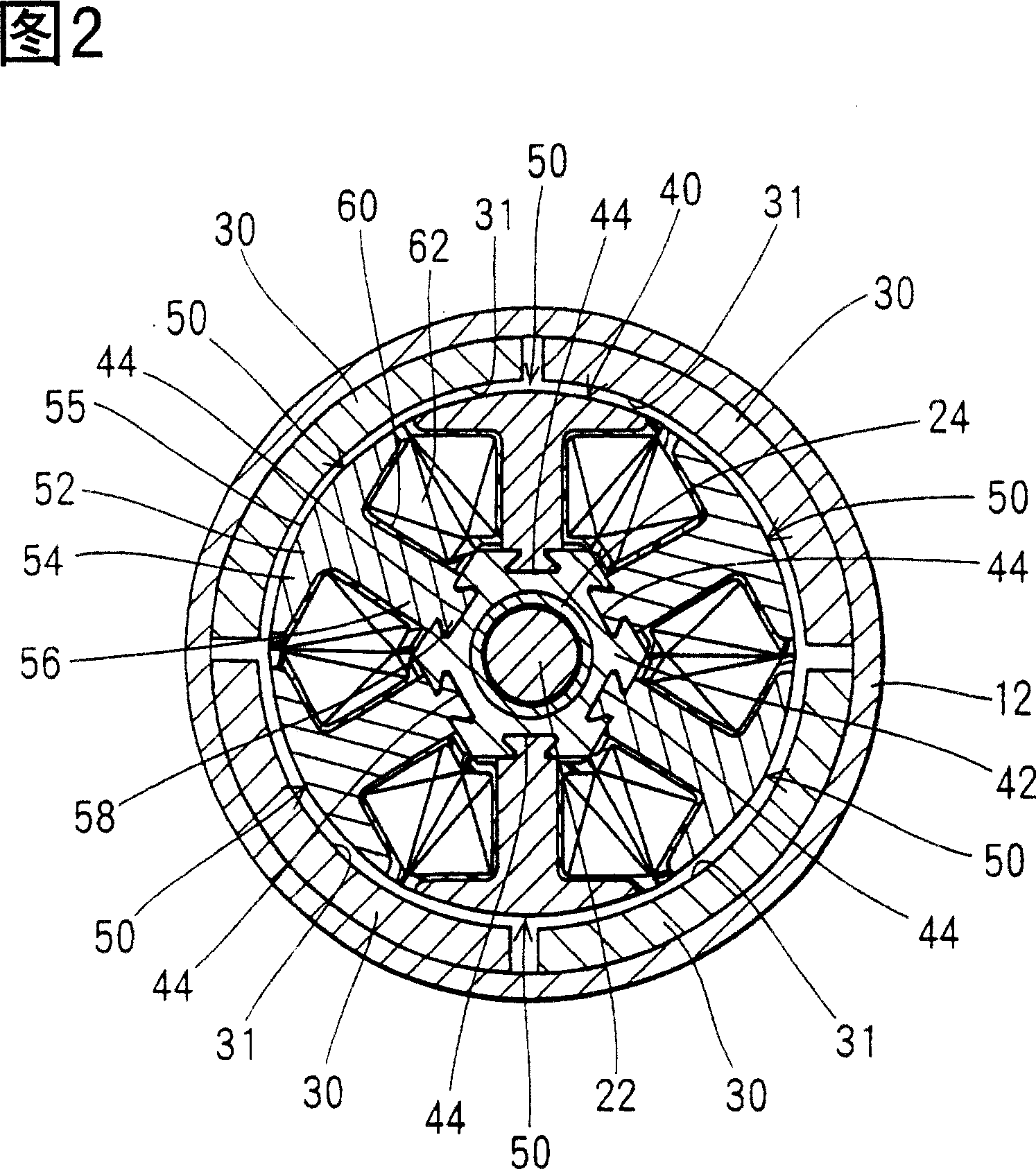

[0034] At the outer edge of the disc impeller 20, a plurality of fin grooves are formed. When the impeller 20 rotates with the armature 40, a pressure difference is generated between the front and rear of the vane slot due to fluid friction. By repeatedly pressurizing the vane slots, the pressure of the fuel in the pump passage 102 is increased. Due to the rotation of the impeller 20, the fuel is sucked in from...

no. 2 example and

[0060] [Second Embodiment and Third Embodiment]

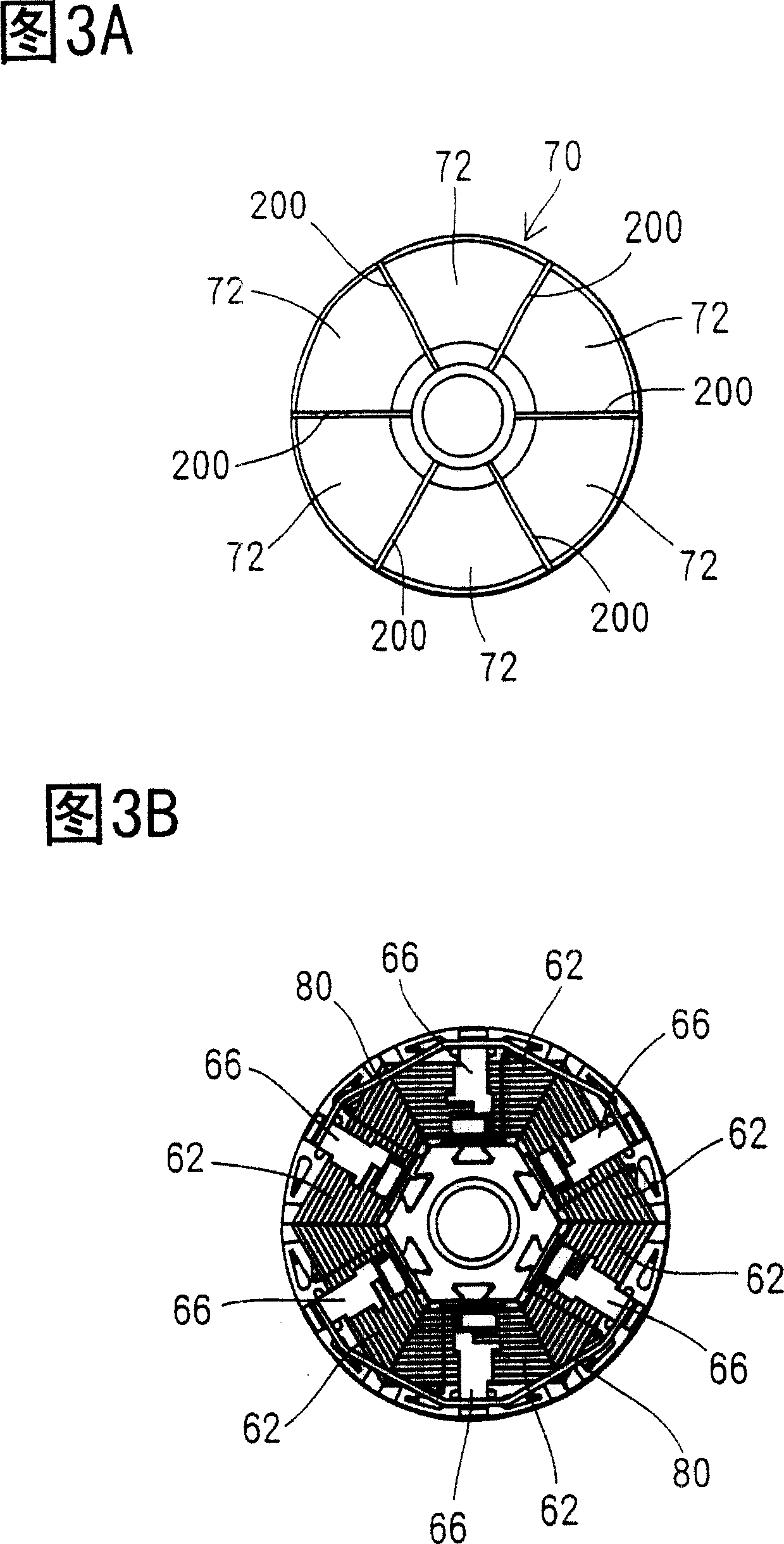

[0061] Referring to Fig. 13 and Fig. 14, except that the connection relationship between the coil 62 and the sector 72, and the connection relationship between each coil 62 are different, the structures of the second embodiment and the third embodiment are the same as those of the first embodiment The structures basically correspond. In the first embodiment, the ends of the respective coils 62 are connected together on the side of the armature 40 remote from the commutator 70 , that is, outside the commutator 70 . On the other hand, in the second embodiment, the ends of the coil 62 are electrically connected to the sector 72 in the commutator 90, and the other ends of the coil 62 are also connected to each other in the commutator 90. of. In the wiring relationship in the second embodiment, coil (a1) 62 and coil (a2) 62, coil (b1) 62 and coil (b2) 62, and coil (c1) 62 and coil (c2) 62 are respectively connected in series to T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com