Shock-resistant culvert pipe with large section and circumferential stress and production process thereof

A large cross-section, anti-seismic culvert technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of poor crack resistance, high engineering cost, and no engineering examples, etc., to achieve improved earthquake resistance, enhanced performance, and hoop bearing reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

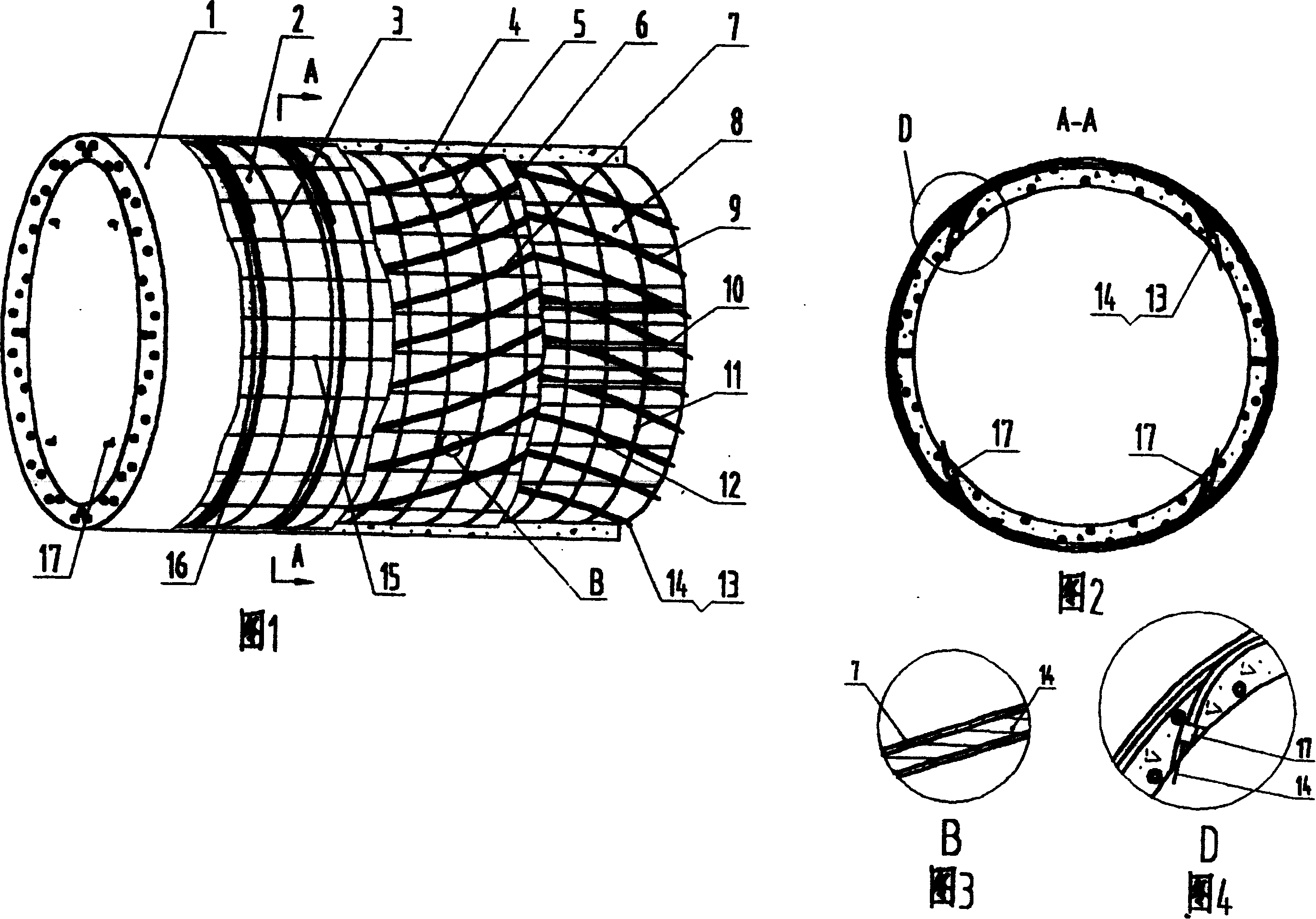

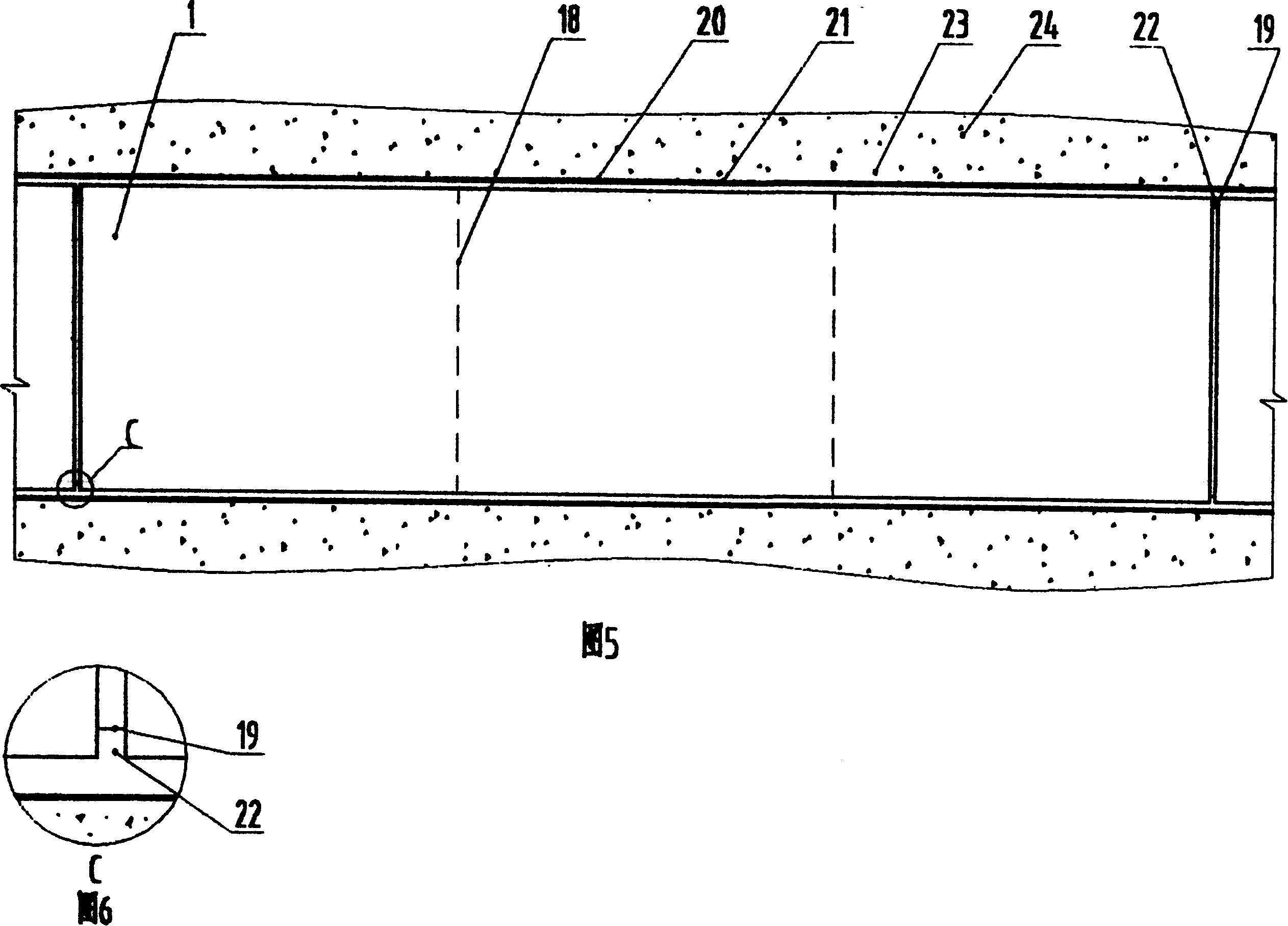

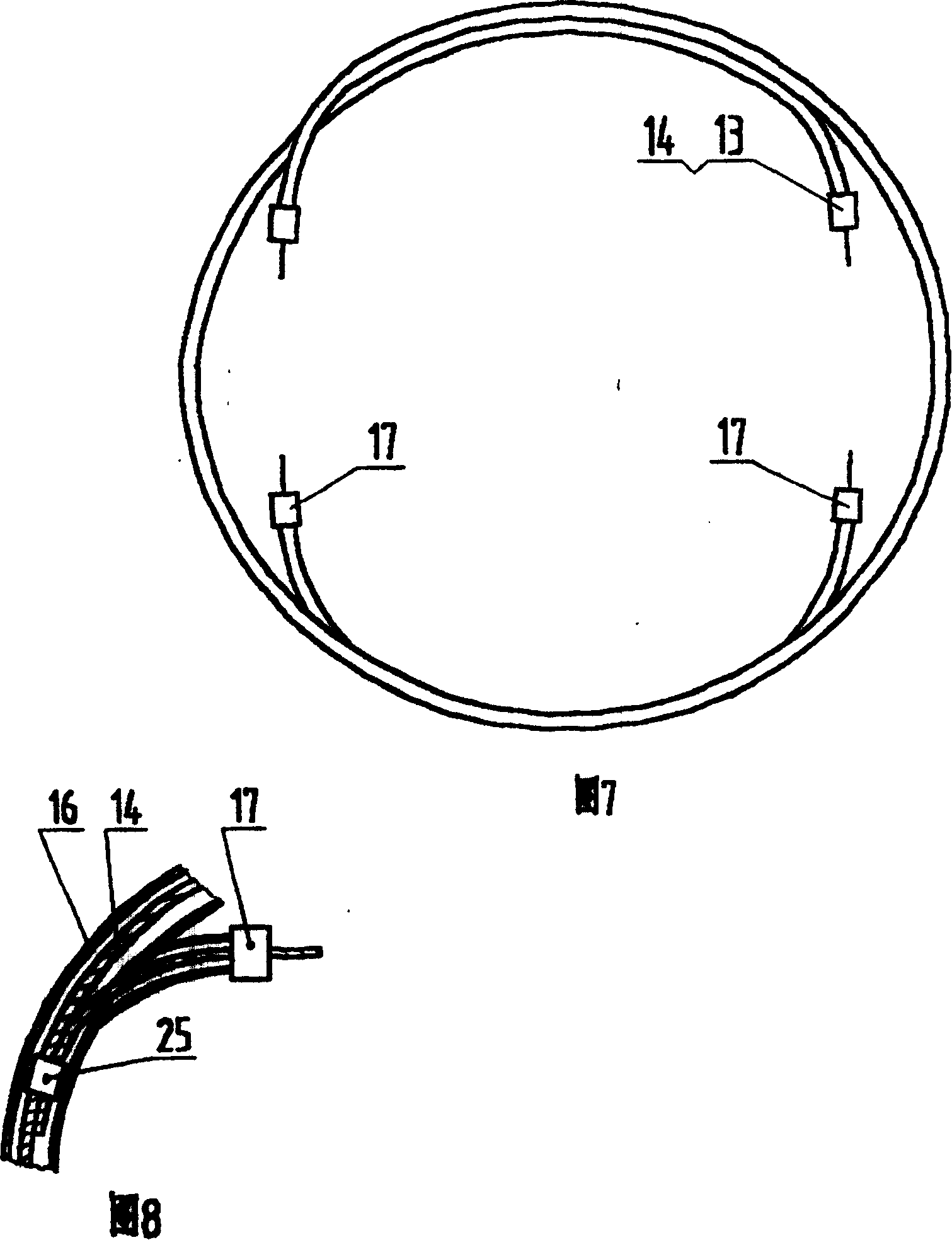

[0039] As shown in the accompanying drawings, the present invention includes a concrete culvert body 1 and a cylindrical skeleton made of longitudinal and ring bars arranged in the culvert body 1, which is characterized in that the cylindrical skeleton is composed of an inner layer skeleton 8, The middle frame 4 and the outer frame 2 are formed, and the inner frame 8 and the middle frame 4 are uniformly fixed on the inner frame 8 and the middle frame 4 respectively. There are prestressed steel strands produced by tension, and a hoop tube 16 is arranged on the outer skeleton 2, and the two ends are anchored by anchors 13 arranged on the inner wall of the culvert body 1, and the inner wall of the culvert body 1 is provided with The pulling anchor 17 connected with the inner steel strand of the hoop tube 16 is provided with a rubber-plastic isolation layer 20 between the outer wall 21 of the culvert and the concrete outer lining 23. The pulling anchor 17 and the hoop steel strand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com