Connected concrete prefabricate combined bin and building method thereof

A prefabricated assembly and concrete technology, which is applied in the direction of buildings, building types, and large-capacity bulk material storage, etc., can solve the problems of failure to replace reinforced concrete silos, large temperature fluctuations and condensation, and easy mildew during storage, etc. problems, to achieve the effect of stable overall performance, fast installation speed, and improved storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

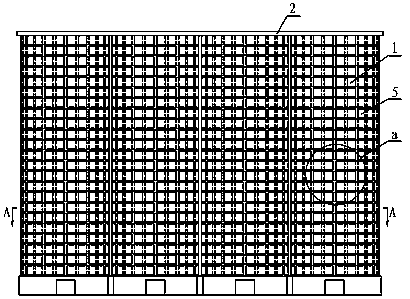

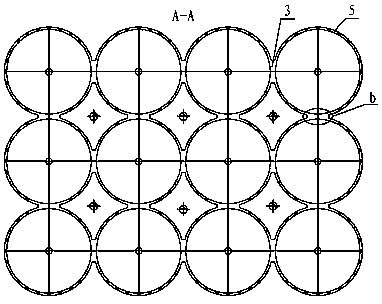

[0068] A conjoined concrete prefabricated assembly warehouse, which consists of: a cylinder body 1, the upper part of the cylinder body is connected to the warehouse roof 2, the cylinder body has an assembled structure, and the connection part 3 between adjacent cylinder bodies It has an arc-shaped circumferential steel bar A4 and a longitudinal steel bar A-piece number 41 perpendicular to the arc-shaped circumferential steel bar. The rest of the cylinder is assembled from a group of arc-shaped prefabricated panels 5. The arc-shaped circumferential steel bar 4 in the connection part 3 between the bodies and the arc-shaped circumferential steel bar 6 in the arc-shaped prefabricated slab jointly constitute the circular circumferential tension bar of the cylinder; the assembly position 7, The vertical pouring channel 8 in the arc-shaped prefabricated slab and the joint between the cylinder and the arc-shaped prefabricated slab are poured with concrete along with the construction t...

Embodiment 2

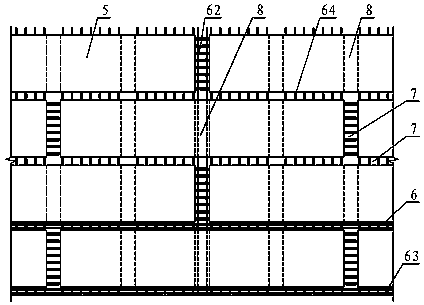

[0070] In the one-piece concrete prefabricated assembly warehouse described in Example 1, the arc-shaped prefabricated slab has an arc-shaped reinforcement skeleton, and the arc-shaped reinforcement skeleton includes the arc-shaped circumferential reinforcement B6 and the longitudinal reinforcement B61 The circumferential reinforcement B6 protruding horizontally on both sides is used as a steel structure connector, and the vertical longitudinal reinforcement B-piece number 61 is inserted into the space formed by the steel structure connector to form a vertical reinforcement cage 62; The arc-shaped circumferential steel bar A-item number 4 is an extension of the arc-shaped circumferential steel bar B6, or a part of the prefabricated part of the connecting part between the cylinders;

[0071] In the same way, at the height direction connection position between the curved prefabricated slabs, the longitudinal steel bars protruding vertically on the upper and lower sides are used a...

Embodiment 3

[0075] In the conjoined concrete prefabricated assembly warehouse described in embodiment 1 or 2, the connecting part between the cylinders includes arc-shaped circumferential steel bars A4 and The longitudinal steel bar A41 connected with the arc-shaped circumferential steel bar A4 is inserted into the space formed by the arc-shaped circumferential steel bar B6 and the arc-shaped circumferential steel bar A4. 41 forms a vertical reinforcing cage 42; between the arc-shaped circumferential reinforcing bar A and the arc-shaped circumferential reinforcing bar B, adopt welding, threaded connection, sleeve connection or semi-circular staggered position to insert vertical reinforcing bars to connect, Concrete is cast in-situ as column in the connection position and the pouring channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com