Electrode and capacitor provided with said electrode

A capacitor and electrode technology, which is applied in the direction of electrolytic capacitors, electrolytic capacitor manufacturing, capacitors, etc., can solve the problem of reducing the withstand voltage strength of capacitors, and achieve the effect of improving long-term stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

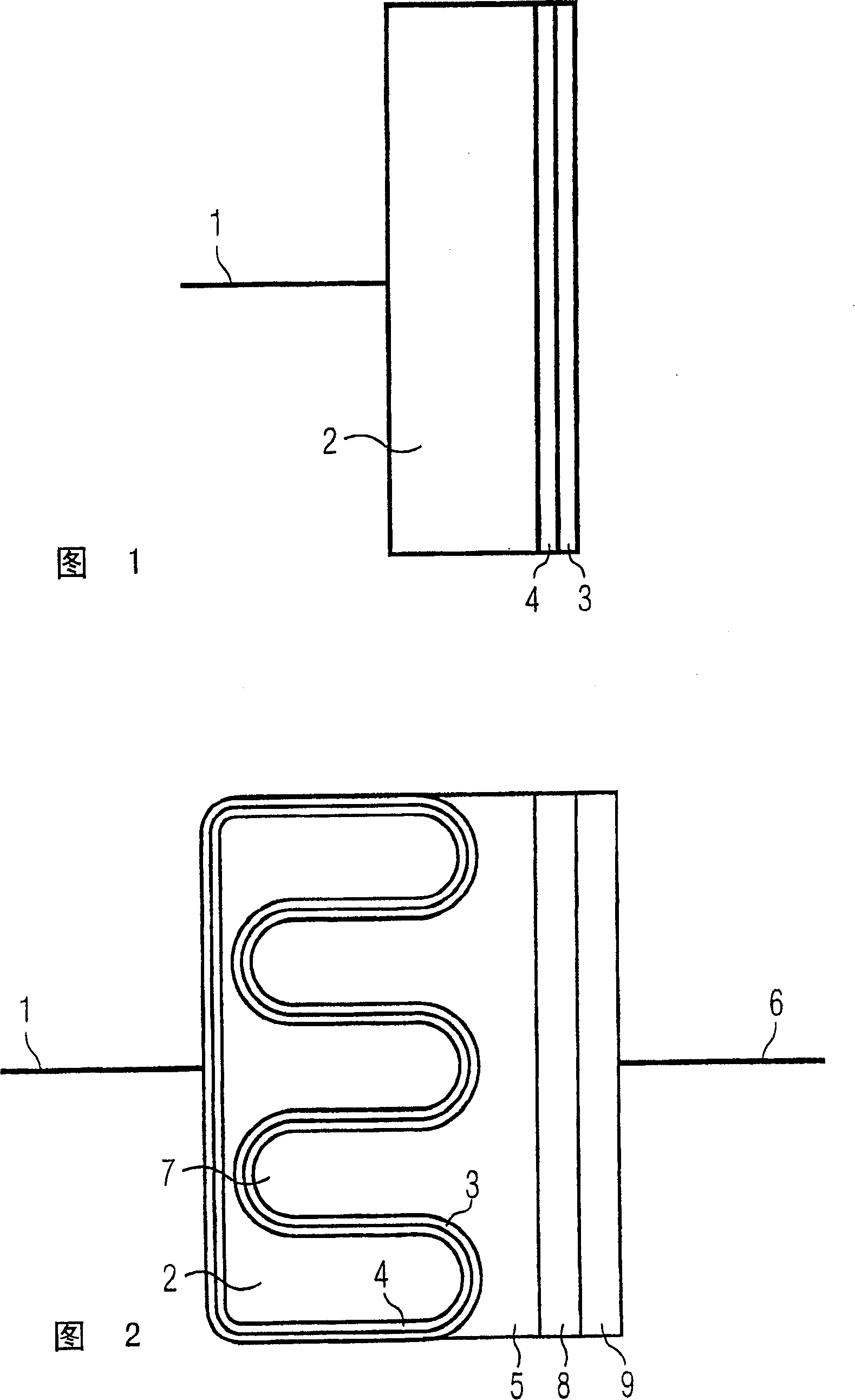

[0025] FIG. 1 shows an electrode with an electrode body 2 which is electrically conductively connected to an electrode discharger 1 . A dielectric layer 3 is provided on the surface of the electrode body 2 . An intermediate layer 4 is arranged between the electrode body 2 and the dielectric layer 3 .

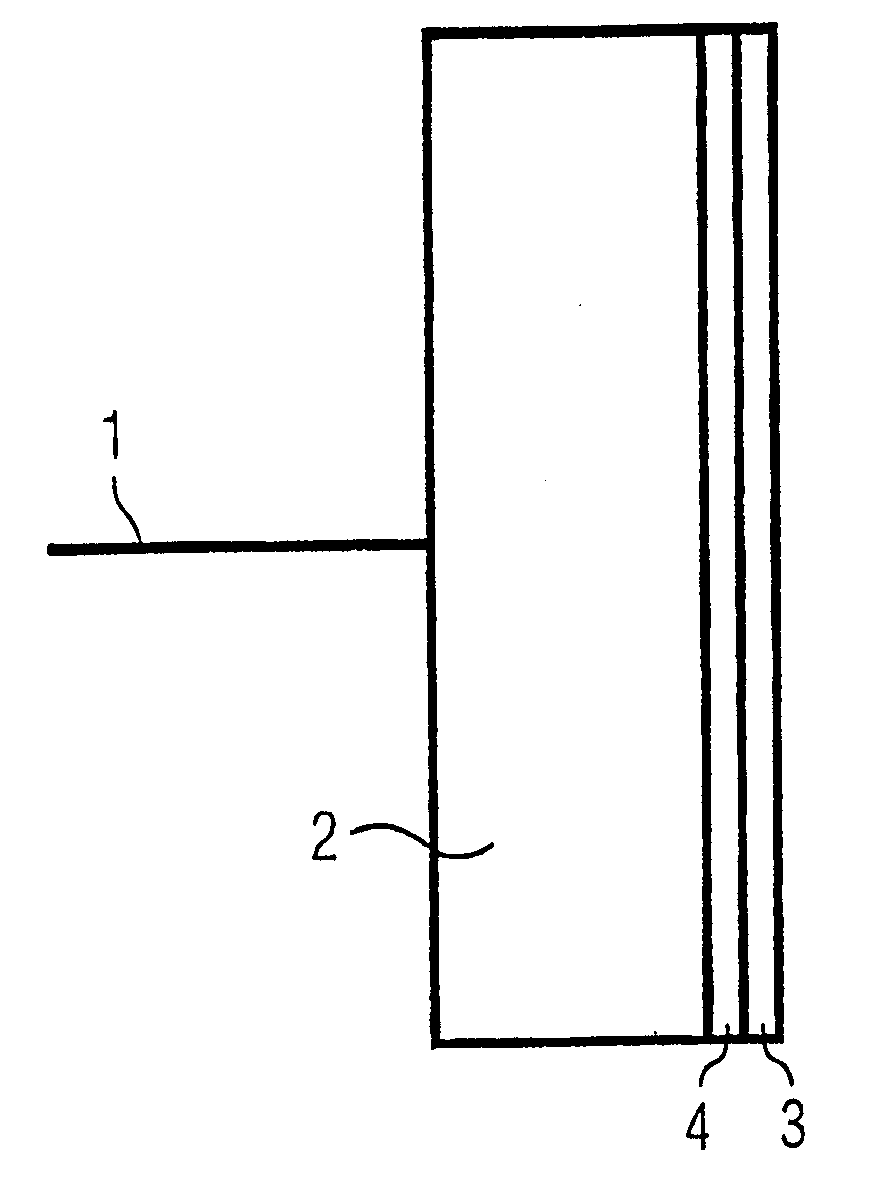

[0026] Fig. 2 shows an electrolytic capacitor using the electrode of the present invention as an anode, wherein the electrode is equivalent to the structure of Fig. 1, and the electrode body 2 of the electrode is a porous body with pores 7. The electrode body 2 preferably contains a unidirectionally conductive metal, such as tantalum or niobium, from which a dielectric oxide can be produced by anodic oxidation.

[0027] The electrode body 2 is preferably made of an alloy of niobium and vanadium in powder form. Wherein, the electrode discharger 1 is made into the shape of a metal wire or a large-area metal discharger. For example, tantalum-containing wires or niobium-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com