Paper-making colorant and preparation method thereof

A technology of colorants and toners, which is applied in the preparation of paper-making colorants, the preparation of colorants, and the deployment of colorants for paper hue. It can solve the problems of easy yellowing, uneven coloring, and paper color difference, and achieve High retention rate, good affinity, and the effect of improving printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

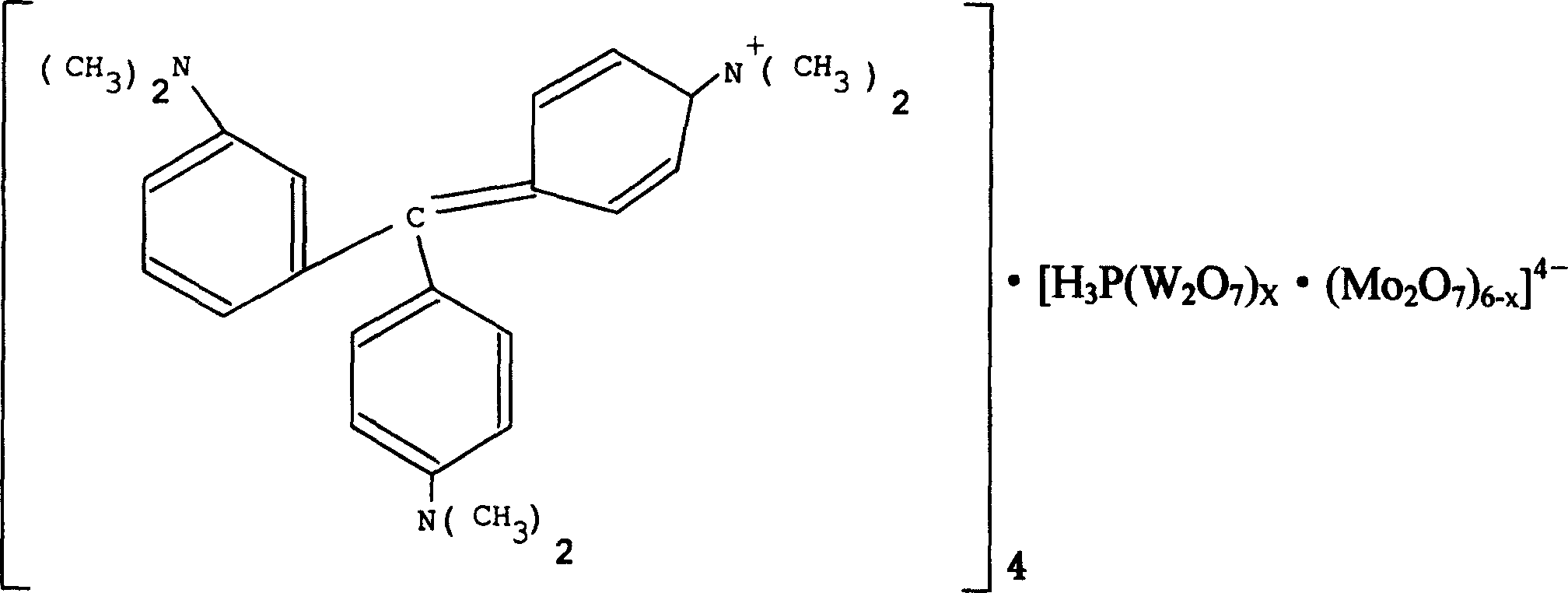

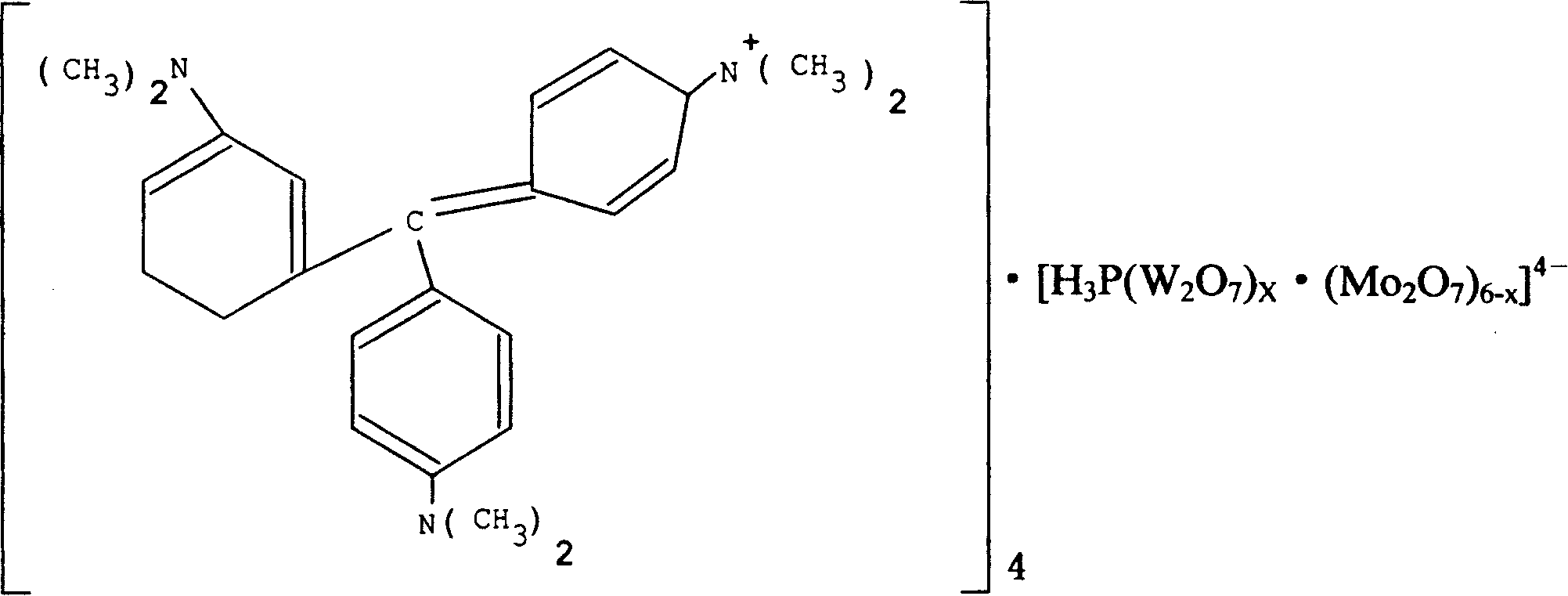

[0040] Commercial toner RVL violet contains inorganic salts and metal salts, including phosphorus and molybdate in its structure, so it has good hydrophilicity. However, it swells when making water-based color paste, and then flocs appear. Through a large number of experiments, it is found that this shortcoming can be solved by the method of pretreatment of commercial toner RVL purple, which has good hydrophilicity, that is, first Add 100Kg of toner RVL purple into the container, then add 100Kg of deionized water, beat and stir in the container for 10 minutes, so that the pigment is completely mixed with water, adjust the pH value between 7.2-7.5 with triethanolamine, and then use The high-density non-woven fabric is dehumidified by vacuum to filter out the water and inorganic salts in the pigment. Measure the water content of the pigment cake left on the filter cloth, and control the solid water content to about 50%, so as to facilitate feeding in the next step.

[0041] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com