Two-phase fluid grid and capacitor chromatography imaging method

A technology of capacitance tomography and fluid, which is applied in the direction of material capacitance, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., and can solve problems such as the inability to realize real-time imaging of two-phase fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

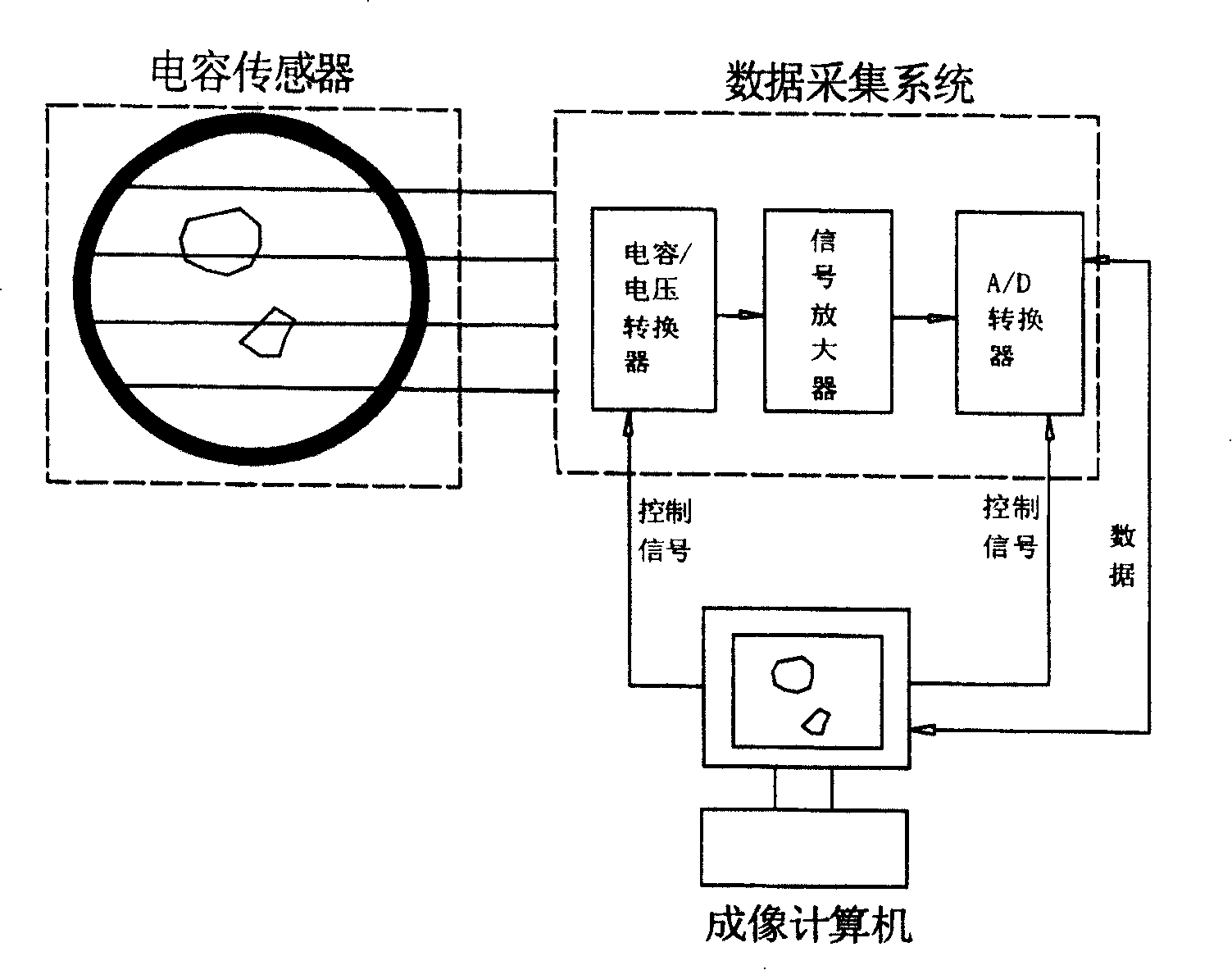

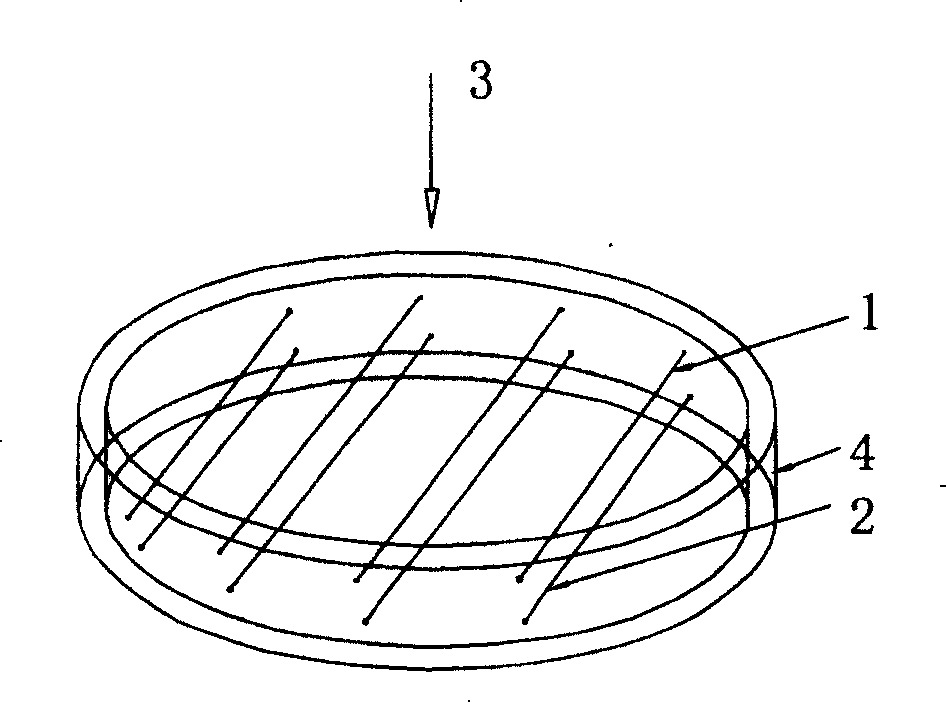

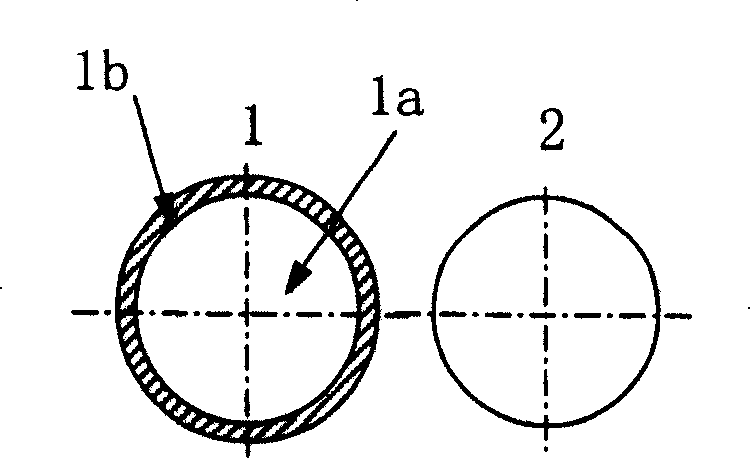

[0038] figure 1 It is an intervening network capacitance tomography imaging system prepared according to the method of the present invention, which is composed of three parts: an intervening capacitance sensor, a data acquisition system and an imaging computer. Interventional capacitive sensor layouts such as figure 2 As shown, the insulated wire layer 1 and the wire layer 2 are arranged in the capacitive sensor, and the distance between the two layers is very close and parallel to each other. The insulated wire 1 or wire 2 of each layer is also parallel to each other and vertically fixed to the rotatable sensor housing. 4, the rotating mechanism is connected with the pipeline seal. Here each insulated wire 1 is used as the generating pole of the capacitance in the capacitive sensor, and the corresponding wire 2 directly behind them is the wire used to measure the corresponding capacitance, such as image 3 shown. The insulated wire 1 is coated with a thin insulating laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com