Process and device for cell pole piece pressurization and injection

A battery pole piece and liquid injection device technology, which is applied in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the interference and influence of the external environment (especially moisture), and may not guarantee sufficient pole pieces The wetting effect and the unsatisfactory wetting effect of the inner pole piece of the cell have achieved the effect of significant improvement, gas reduction, and enhanced wetting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

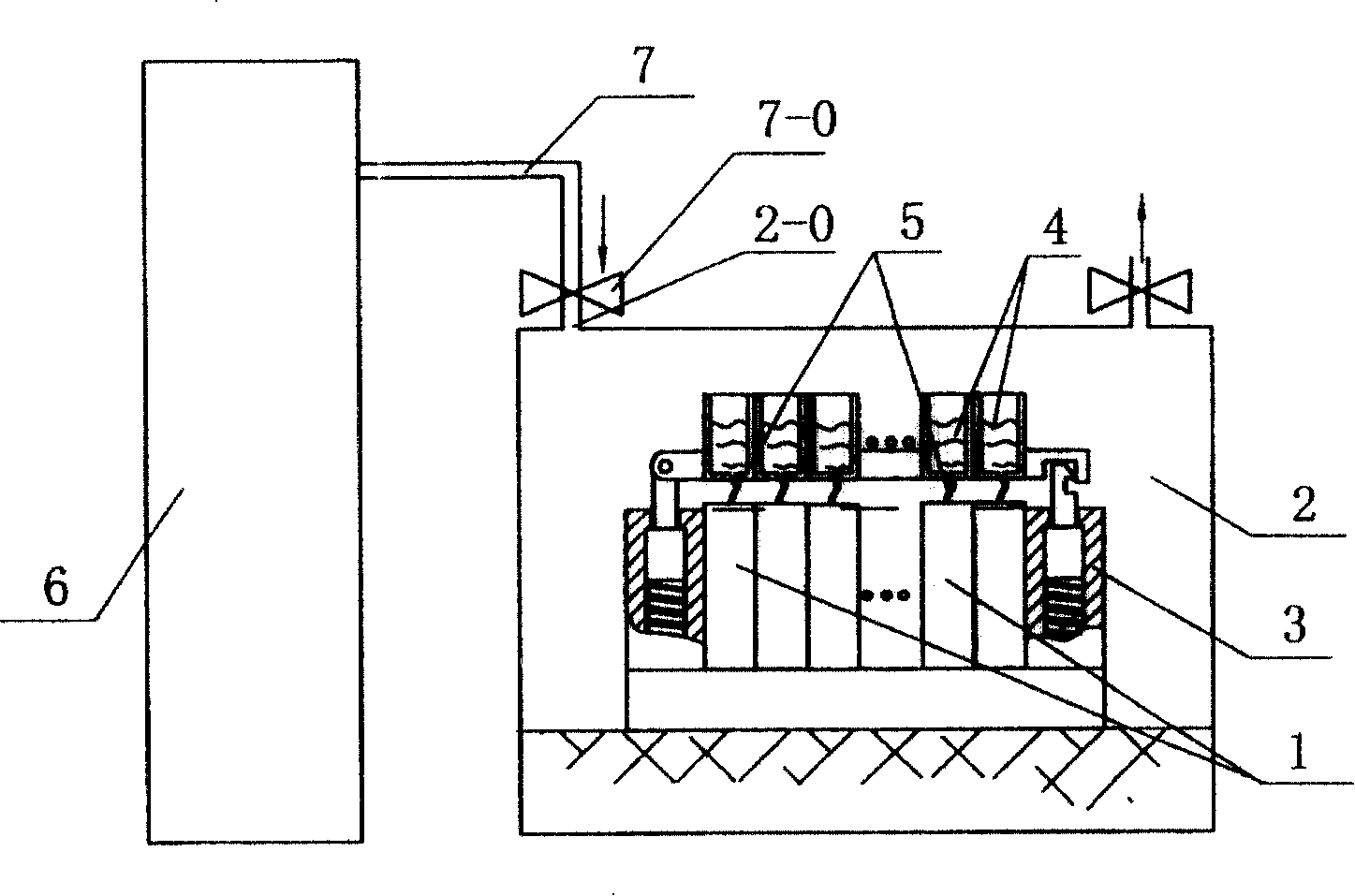

[0022] Such as figure 1 Embodiment 1 of a pressurized liquid injection device for battery pole pieces is shown, the battery 1 includes a casing with an upward liquid injection hole and a pole piece (not shown in detail) inside it, and the pressurized injection The liquid device includes a vacuum chamber 2, an evacuator (not shown in detail), and a port 2-0 communicating with the pressurization device is opened on the wall of the vacuum chamber 2; the pressurized liquid injection device also includes a clamp 3 for holding the battery 1 , The clamp 3 is provided with a liquid container 4 for containing the electrolyte, and the lower part of the liquid container 4 is provided with a pipe 5 communicating with the liquid injection hole of the battery 1 .

[0023] There is a detachable connection between the clamp 3 and the liquid container 4 . The clamping length of the clamp 3 can be adjusted, and the liquid container 4 on the clamp 3 is provided with a connecting position and a ...

Embodiment 2

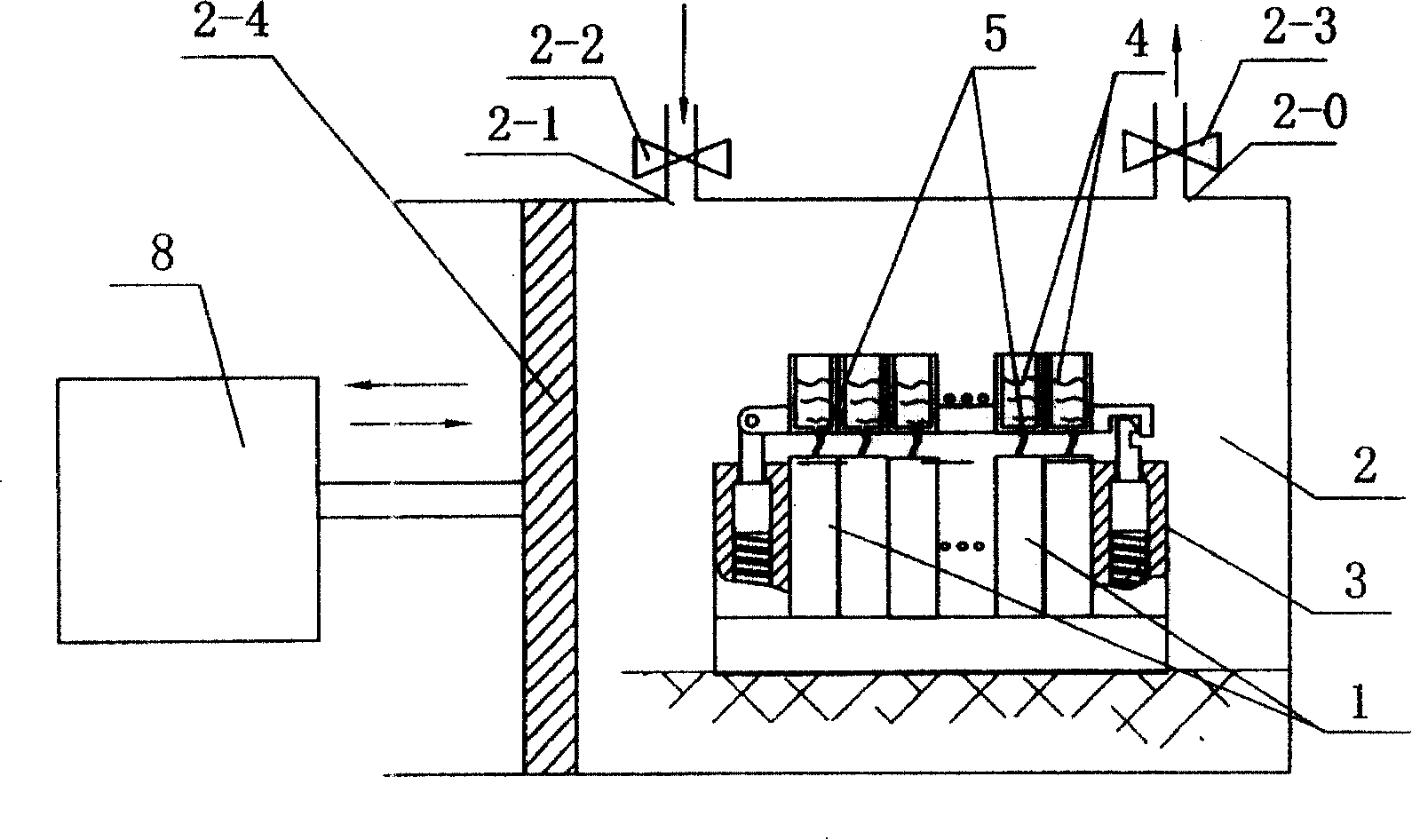

[0027] Such as figure 2 Example 2 of a pressurized liquid injection device for battery pole pieces is shown, the battery 1 includes a shell with an upward liquid injection hole and a pole piece (not shown in detail) inside it, and the pressurized injection The liquid device includes a vacuum chamber 2 and an evacuator (not shown in detail), and the wall of the vacuum chamber 2 is provided with a port 2-0 communicating with the booster device; the pressurized liquid injection device also includes a clamp 3 for holding the battery 1 , The fixture 3 is provided with a liquid container 4 containing the electrolyte, and the lower part of the liquid container 4 is provided with a pipe 5 communicating with the liquid injection hole of the battery 1 .

[0028] There is a detachable connection between the clamp 3 and the liquid container 4 . The clamping length of the clamp 3 can be adjusted, and the liquid container 4 on the clamp 3 is provided with a connecting position and a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com