Separation method of vinyl-acetate resin from chromium-contained effluent

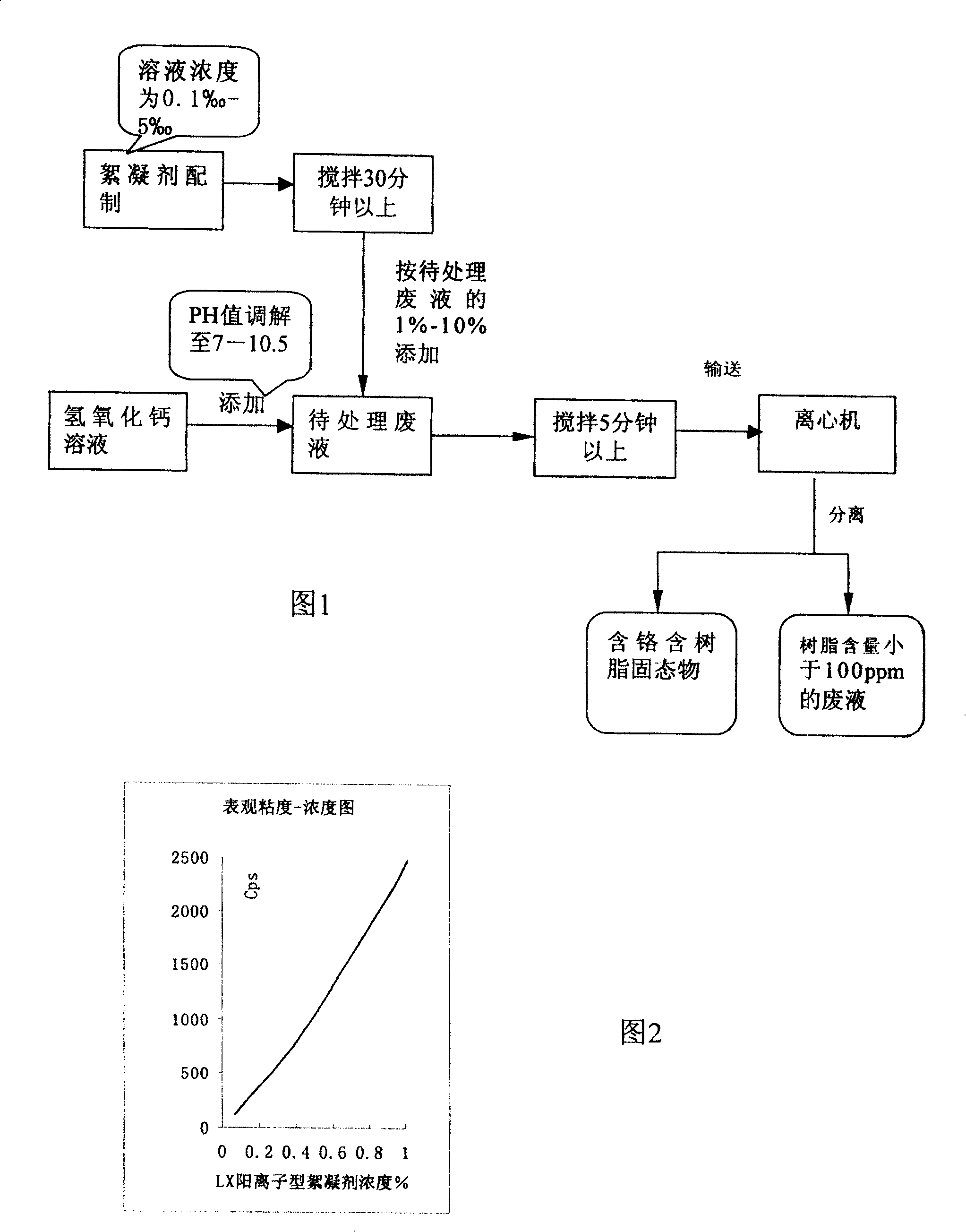

A technology of vinyl acetate resin and separation method, which is applied in the direction of neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of blocked pipelines and valves, so as to promote resin precipitation, improve flocculation effect, and facilitate separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Lead the waste liquid containing hexavalent chromium into the liquid storage tank made of stainless steel or polypropylene;

[0041] Add calcium hydroxide to the waste liquid containing hexavalent chromium to make the pH value of the waste liquid reach 7;

[0042] Prepare LX cationic flocculant solution, the solution concentration is 0.1‰, and the stirring time is 30 minutes;

[0043] Add LX cationic flocculant solution according to 1% of the waste liquid mass, and stir with a stainless steel paddle stirrer, and keep the shear rate at 8s -1 , to promote the dispersion of flocculant in waste liquid;

[0044] Stir for 5 minutes;

[0045] Use the pump to send the liquid to the frequency conversion sedimentation centrifuge, the working frequency is 30-50HZ;

[0046] The mixed liquor with precipitates is separated into solids in a decanter centrifuge.

Embodiment 2

[0048] Lead the waste liquid containing hexavalent chromium into the liquid storage tank made of stainless steel or polypropylene;

[0049] Add calcium hydroxide to the waste liquid containing hexavalent chromium to make the pH value of the waste liquid reach 9;

[0050] Prepare LX cationic flocculant solution, the solution concentration is 2‰, and the stirring time is 45 minutes;

[0051] Add LX cationic flocculant solution according to 5% of the waste liquid mass, and stir with a stainless steel paddle stirrer, and keep the shear rate at 14s -1 , to promote the dispersion of flocculant in waste liquid;

[0052] Stir for 7 minutes;

[0053] Use the pump to send the liquid to the frequency conversion sedimentation centrifuge, the working frequency is 30-50HZ;

[0054] The mixed liquor with precipitates is separated into solids in a decanter centrifuge.

Embodiment 3

[0056] Lead the waste liquid containing hexavalent chromium into the liquid storage tank made of stainless steel or polypropylene;

[0057] Add calcium hydroxide to the waste liquid containing hexavalent chromium to make the pH value of the waste liquid reach 10.5;

[0058] Prepare LX cationic flocculant solution, the solution concentration is 5‰, and the stirring time is 60 minutes;

[0059] Add the LX cationic flocculant solution according to 10% of the mass of the waste liquid, and stir with a stainless steel paddle stirrer, and keep the shear rate at 20s -1 , to promote the dispersion of flocculant in waste liquid;

[0060] Stir for 8 minutes;

[0061] Use the pump to send the liquid to the frequency conversion sedimentation centrifuge, the working frequency is 30-50HZ;

[0062] The mixed liquor with precipitates is separated into solids in a decanter centrifuge.

[0063] In the above three embodiments, the solid obtained after centrifugal dehydration is a mixture cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com