Converter refined slaging medium and slagging technique

A slagging agent, converter steelmaking technology, applied in the manufacture of converters, etc., can solve the problems of consumption, ladle erosion, high oxidation, etc., to achieve the effect of absorbing more inclusions, good refining effect, and reduced oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Provide the specific embodiment of the present invention on the low-carbon steel grade of Kunming Iron and Steel Plant below.

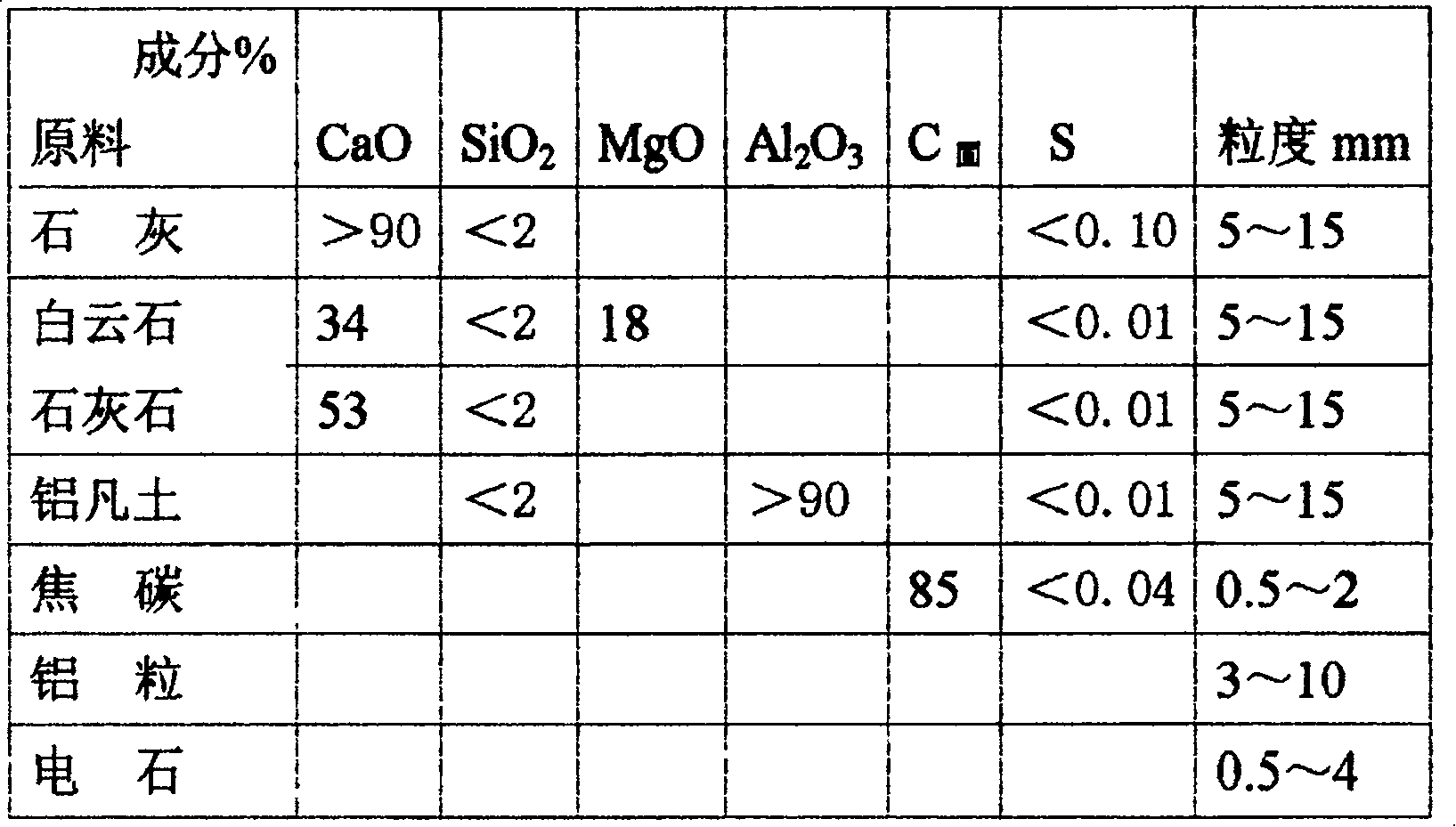

[0048] The chemical composition of raw materials used is shown in Table 1:

[0049]

[0050] 1. Grind the above-mentioned raw materials to 5-15mm, so that the particle size less than 5mm does not exceed 10% of the total amount, heat and bake until the water content is less than 0.5%, and mix well after mixing as required, so that it is evenly mixed. stand-by;

[0051] 2. During the tapping process of the converter, a synthetic slagging agent composed of the following raw materials is added by weight percentage:

[0052] Dolomite 7%, Bauxite 12%,

[0053] Lime 79%, Crude Aluminum 2%,

[0054] The composition of its synthetic slagging agent is as follows:

[0055] CaO 74.29%, SiO 2 4.62%,

[0056] MgO 2.83%, Al 2 o 3 13.65%,

[0057] Al 4.56%, S 0.05%;

[0058] 3. During the refining process of the LF furnace, a low-carbon...

Embodiment 2

[0073] The specific embodiment of the present invention on medium and high carbon steel grades of Kunming Iron and Steel Co., Ltd. is given below.

[0074] The raw material composition is shown in Table 1. Raw material preparation is identical with embodiment 1.

[0075]1. During the tapping process of the converter, a synthetic slagging agent composed of the following raw materials is added by weight percentage:

[0076] Dolomite 8%, Bauxite 13%,

[0077] Lime 75%, Crude Aluminum 4%,

[0078] The composition of this synthetic slagging agent is as follows:

[0079] CaO 70.89%, SiO 2 6.62%,

[0080] MgO 2.98%, Al 2 o 3 10.79%,

[0081] Al 5.96%, S 0.06%;

[0082] 2. During the refining process of the LF furnace, a medium-high carbon submerged arc slagging agent composed of the following raw materials is added by weight percentage:

[0083] Limestone 20%, Dolomite 15%,

[0085] Calcium carbide 10%, coke 4%,

[0086] The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com