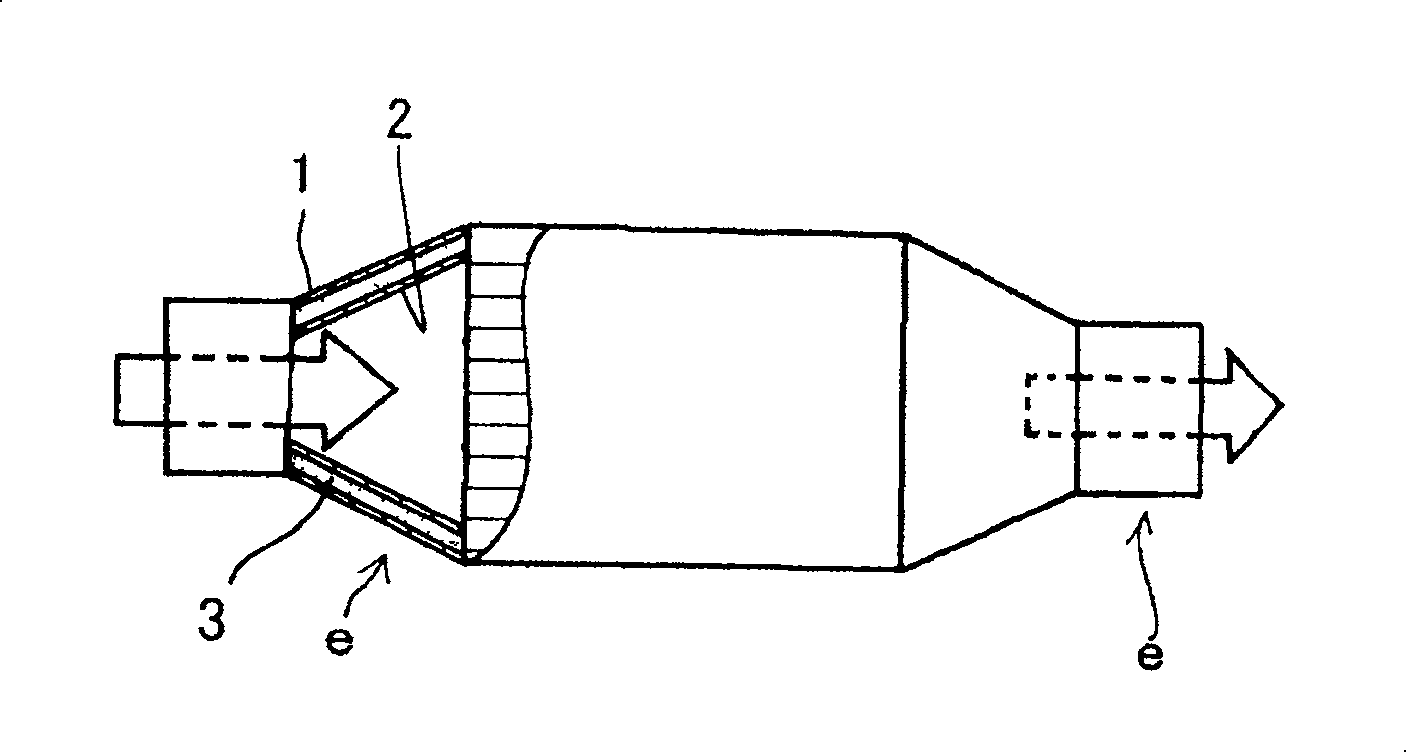

Heat insulating member for end cone portion of exhaust gas conversion apparatus

A waste gas purification device and heat insulation material technology, which is applied in the direction of exhaust device, noise reduction device, scaffolding connection, etc., can solve the problems of poor heat resistance of heat insulation materials, operational problems such as assembly, and durability problems, and achieve resistance to peeling High strength, high heat insulation, and excellent assembly workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

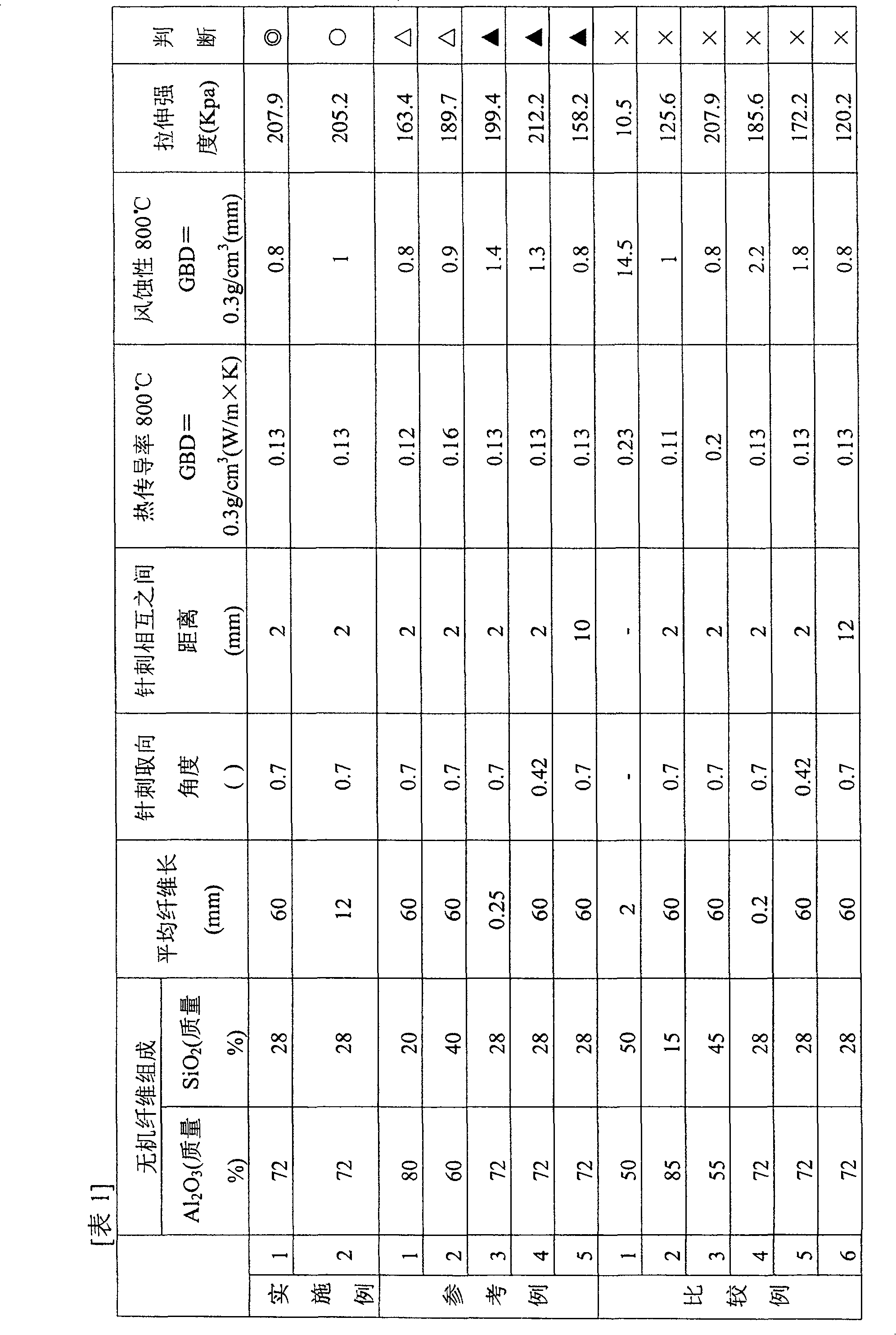

Embodiment 1

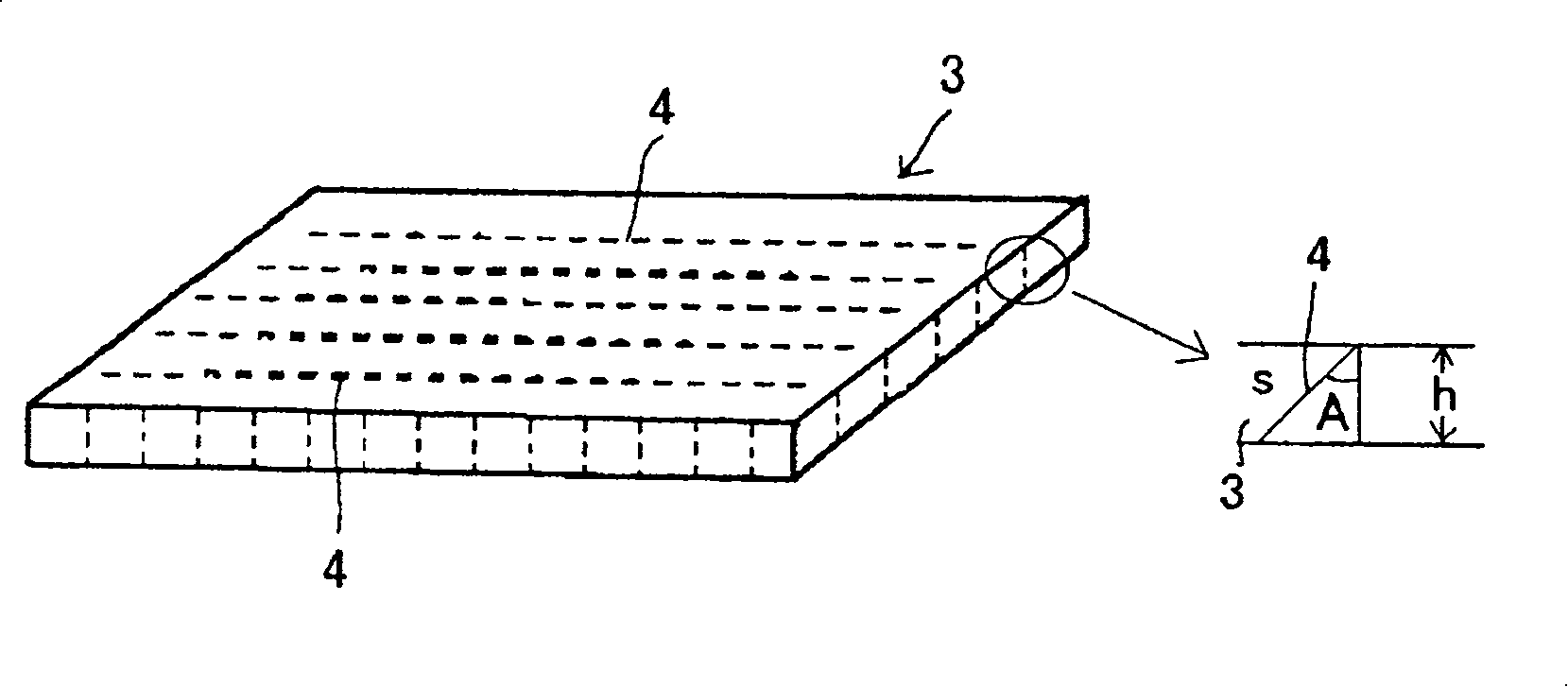

[0038] (mat: production of laminated sheet)

[0039] In an aqueous alkaline aluminum chloride solution with an aluminum content of 70g / l and Al / Cl=1.8 (atomic ratio), add silica sol to make the composition of the alumina fiber Al 2 o 3 : SiO 2 =72±2:28±2, the precursor of the alumina fiber as the ceramic fiber was obtained. Next, an organic polymer such as polyvinyl alcohol is added to the precursor of the alumina fiber, and the concentrated spinning solution is adjusted, and the continuous sheet of the alumina fiber is produced by the blowing method using the spinning solution, and spun The average fiber length is 60 mm by adjusting the air outlet diameter for spraying. A laminated sheet of alumina fibers is produced by lamination.

[0040] The thus-produced alumina fiber laminated sheet was subjected to needle punching so that the distance between the needle punches was 2 mm, and the needle punch orientation angle A was 0.7. Next, the continuous lamination sheet was hea...

Embodiment 2

[0052] (mat: production of laminated sheet)

[0053] In an aqueous alkaline aluminum chloride solution with an aluminum content of 70g / l and Al / Cl=1.8 (atomic ratio), add silica sol to make the composition of the alumina fiber Al 2 o 3 : SiO 2 =72±2:28±2, the precursor of the alumina fiber as the ceramic fiber was obtained. Next, an organic polymer such as polyvinyl alcohol is added to the precursor of the alumina fiber, a concentrated spinning solution is adjusted, and the spinning solution is used for spinning by the blowing method.

[0054] At this time, the air outlet diameter during blowing was adjusted so that the average fiber length of the alumina fibers was 12 mm, and alumina fibers with an average fiber length of 12 mm were obtained. Lamination is then performed to produce a continuous sheet of alumina fibers to produce a continuous sheet of alumina fibers.

[0055] The thus-produced alumina fiber laminate was needle-punched so that the distance between the needl...

reference example 1

[0067] As in Example 1, wherein, in an aqueous alkaline aluminum chloride solution with an aluminum content of 70 g / l and Al / Cl=1.8 (atomic ratio), silica sol is added so that the composition of the alumina fiber is Al 2 o 3 : SiO 2 =80±2: 20±2 Except that, it carried out similarly to Example 1, and obtained the mat of the alumina fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com