Energy-saving fuel battery stack with air supplying apparatus

A fuel cell stack and air supply technology, applied in fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of reducing power density, increasing the complexity of fuel cell systems, and inability to distribute air baffles evenly, etc. To achieve the effect of uniform air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

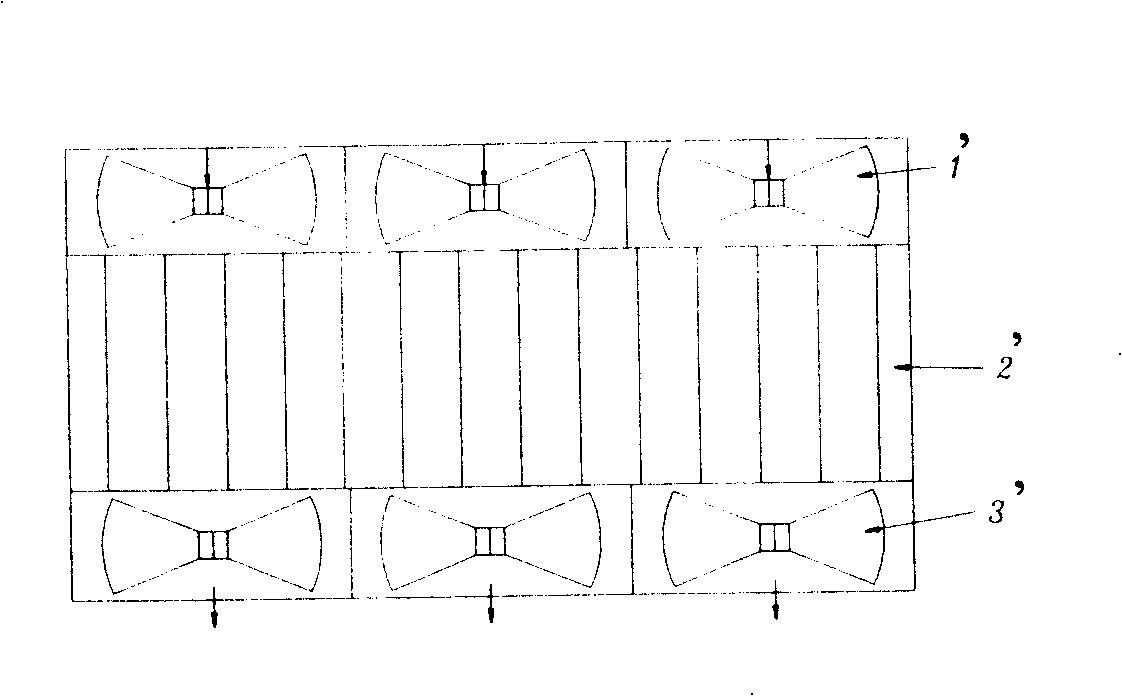

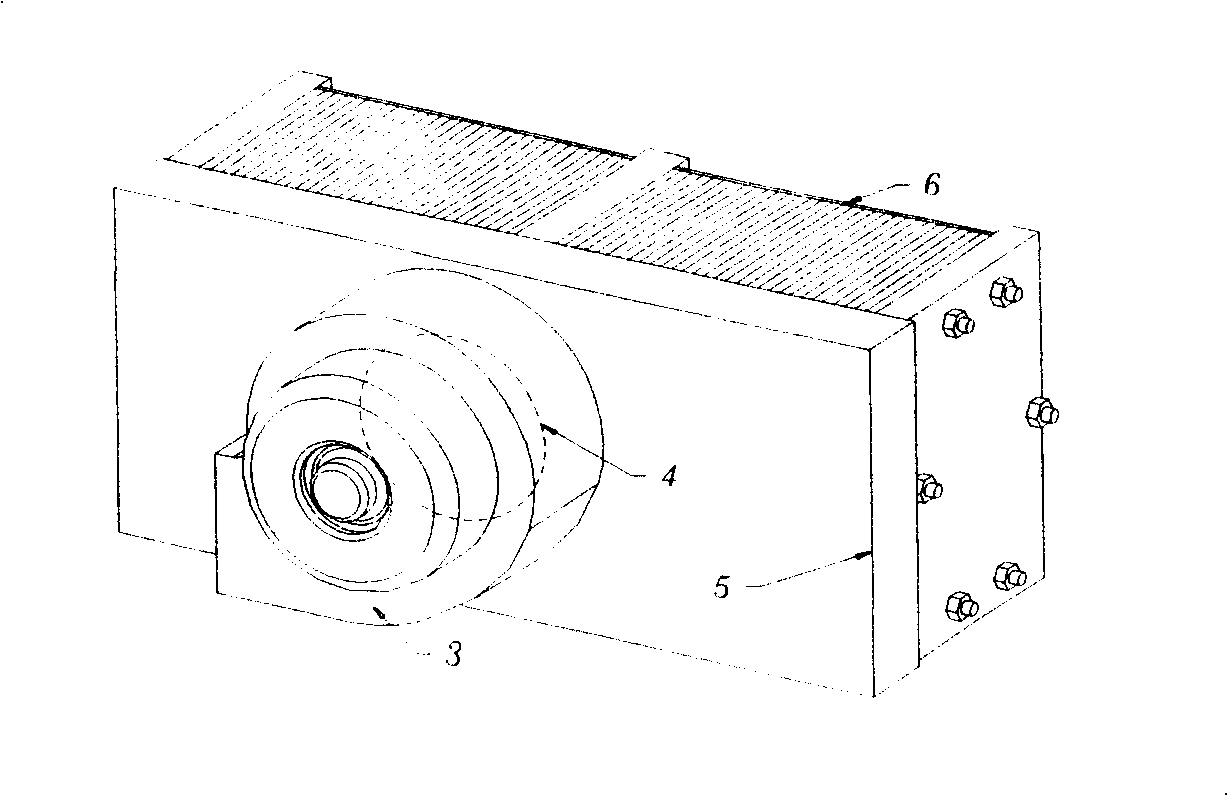

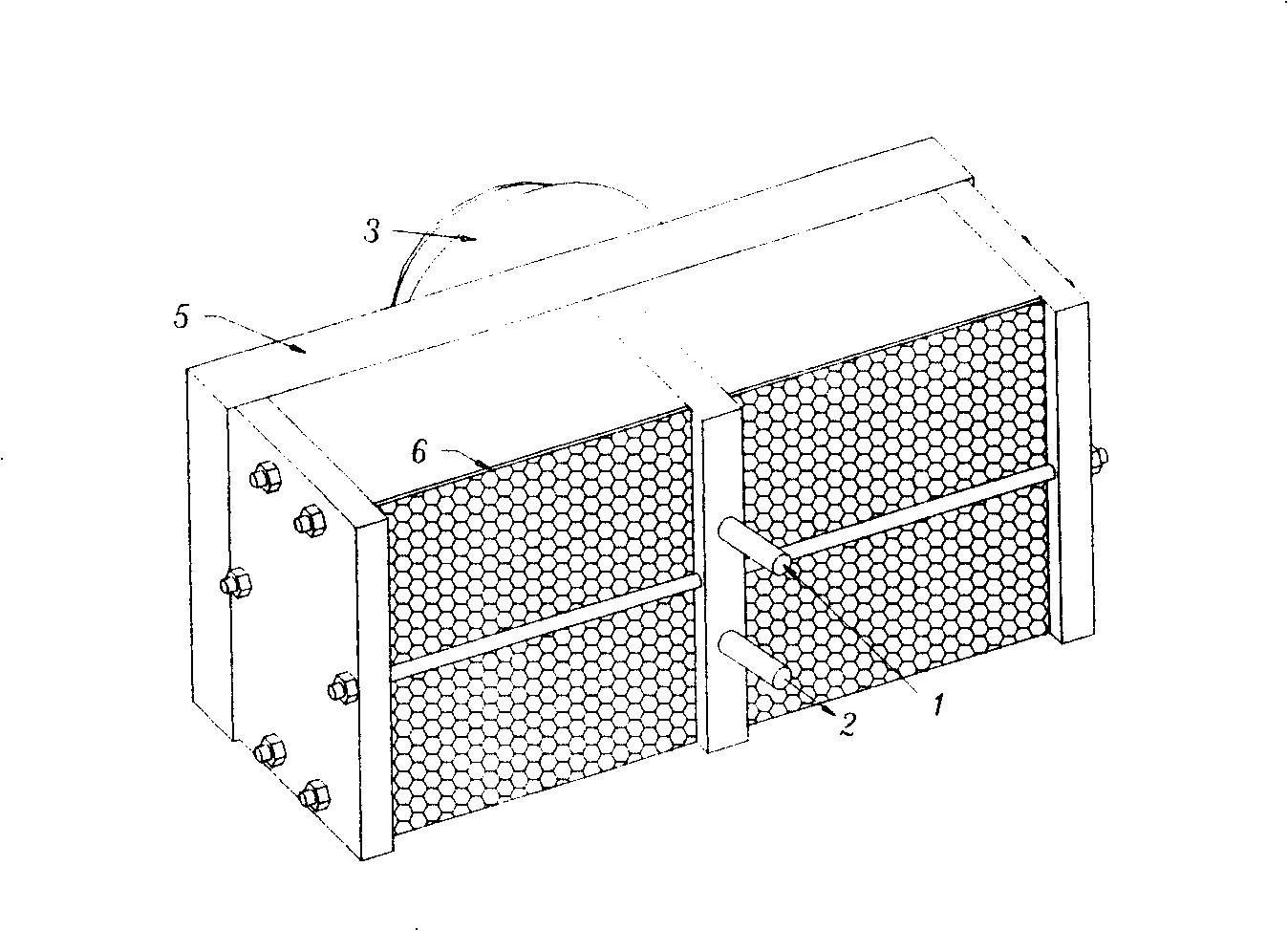

[0030] Such as figure 2 , image 3 As shown, an energy-saving fuel cell stack with an air supply device has a length, width, and height of 275mm×83mm×132mm. The fuel cell stack includes membrane electrodes, guide plates, current collector plates, front and rear end plates, Fasten the tie rods, and also include an air supply device, the air supply device includes a fan 3, and an air collecting cover 5, and the air collecting cover 5 covers the end surface formed by all the air guide grooves on one side of the fuel cell stack, There is a hole 4 in the middle of the air collecting cover, and the opening 4 is connected to the suction port of the fan 3; when the fan is working, a negative pressure is generated due to the action of the air collecting cover 5, so that all the air on the other side of the battery stack Air is sucked in at the end faces where the guide grooves are assembled. A layer of air filter 6 is laid on the end face of all the air guide slots on the other side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com