Gas filling machine capable of automatically sequencing to supply gas

An automatic sorting and filling machine technology, applied to the method of container discharge, the equipment discharged from the pressure vessel, mechanical equipment, etc., can solve the problems of inability to adapt and cannot be used in gas filling sub-stations, etc., to achieve simple operation, The effect of reducing operating costs and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

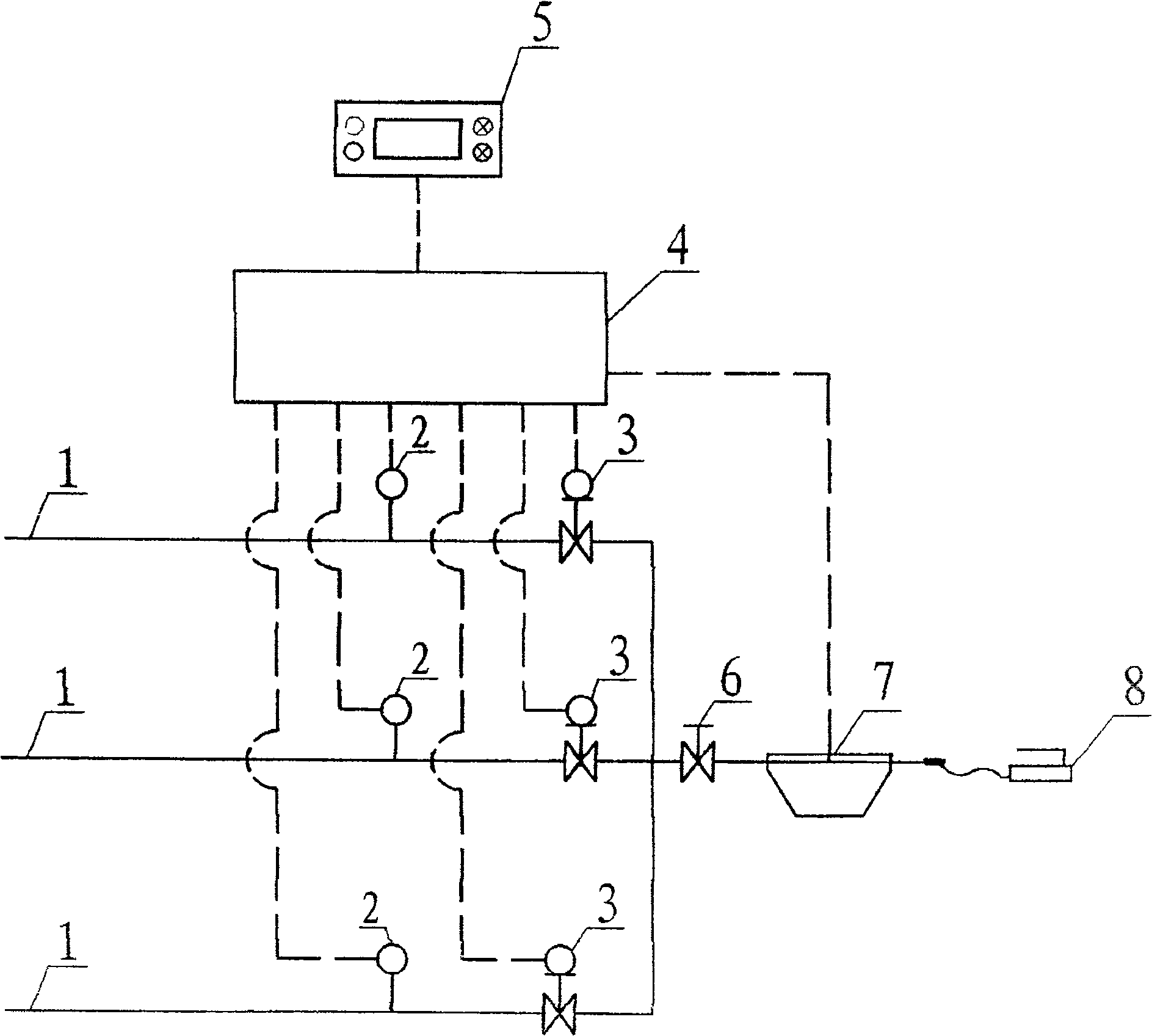

[0009] In the above drawings, the gas filling machine for automatically sorting and taking gas is formed by connecting the gas taking control system, the gas flow meter 7 and the gas filling gun 8 . The air intake control system is composed of three intake pipelines 1 equipped with pressure transmitters 2 and solenoid valves 3 in sequence, and an electronic control panel 4 with a display screen 5 . The electronic control panel 4 is equipped with a microcomputer information processing system, a management system and an acousto-optic prompting system, which can automatically open each solenoid valve 3 in the order of low, medium and high pressure according to the signals of the pressure transmitter 2 on the three intake pipelines 1. Gas, pressure switching time can be adjusted, can set the pressure is too low to remind the replacement of the data of the gas cabinet, then the audible and visual reminder will be given. The medium of the gas flowmeter 7 is natural gas, the maximum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com