A hydraulic natural gas vehicle refueling substation

A technology of hydraulic natural gas and gas filling sub-stations, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, pipeline systems, etc. Problems such as malfunction of operation and high residual pressure of equipment can achieve the effect of small footprint, high safety and high air intake rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

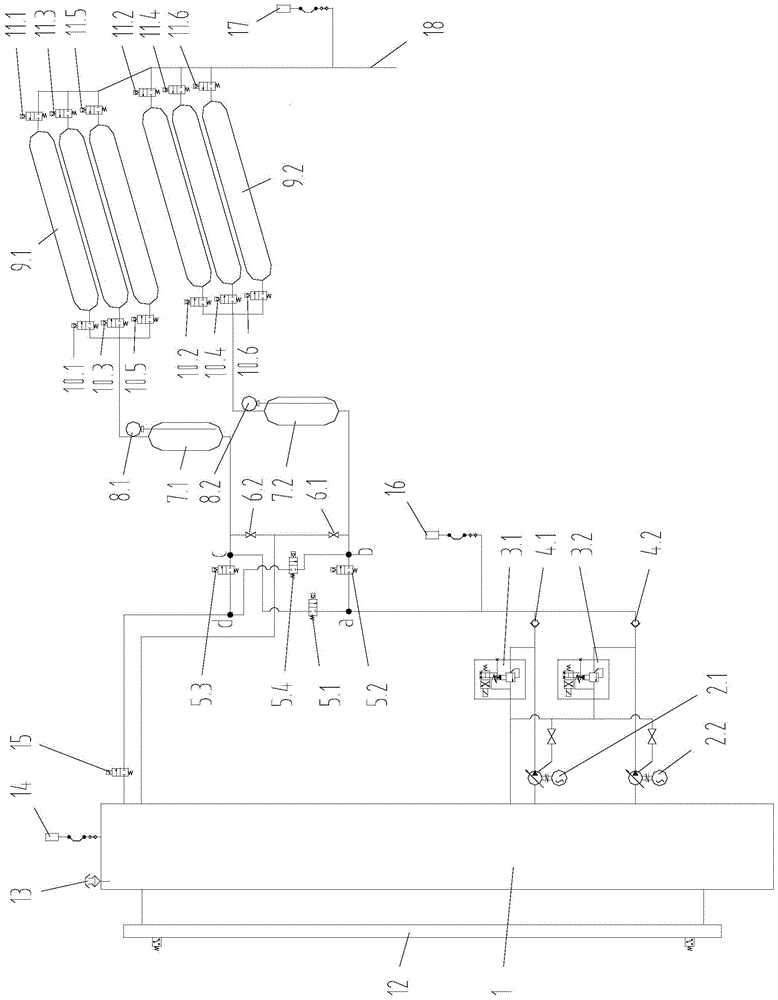

[0008] Such as figure 1 As shown, fuel tank 1, first and second high-pressure oil pumps 2.1 and 2.2, first and second pilot solenoid valves 3.1 and 3.2, first and second one-way valves 4.1 and 4.2, first and fourth pneumatic ball valves 5.1 , 5.2, 5.3, 5.4, the first and second manual ball valves 6.1 and 6.2, the first and second buffer accumulators 7.1 and 7.2, the first and second liquid level transmitters 8.1 and 8.2, the first and second The second gas cylinder group 9.1, 9.2, the first - the sixth oil circuit pneumatic ball valve 10.1, 10.2, 10.3, 10.4, 10.5, 10.6, the first - the sixth gas circuit pneumatic ball valve 11.1, 11.2, 11.3, 11.4, 11.5, 11.6, fuel tank magnetic float flap liquid level gauge 12, fire arresting release cap 13, oil return detection pressure transmitter 14, electromagnetic stop valve 15, oil pressure transmitter 16, air pressure transmitter 17, gas sales interface 18.

[0009] On the fuel tank 1, a fuel tank magnetic float flap liquid level gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com