Method for preparing fibrous light cakium carbonate and reactor

A light calcium carbonate, reactor technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of wide distribution of length and diameter, small size, short residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adding Ca(OH) with a weight concentration of 10% in a jacketed reactor of 15 cubic meters 2 3 tons of water slurry, then add 7 tons of water to dilute to Ca(OH) with a weight concentration of 3.0% 2 Slurry, add 900kgMgCl again wherein 2 ·6H 2 O, stir to make it completely dissolve, pass steam into the jacket of the reactor, heat the slurry to 82°C, and two 15 cubic meter reactors alternately feed continuously to the reactor.

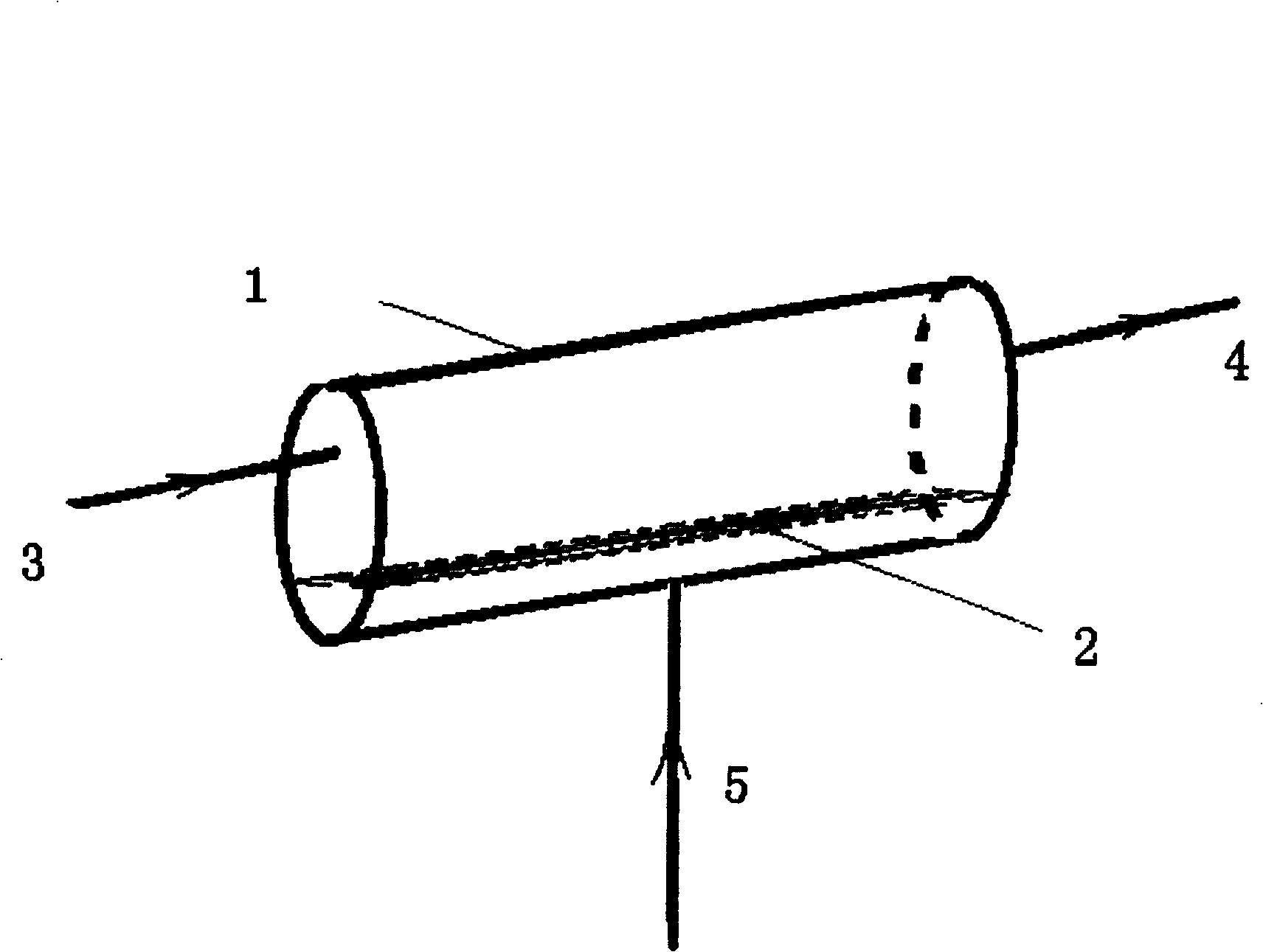

[0032] The heated slurry is pumped into a tube reactor with a length of 50 meters and a diameter of 40 cm. The liquid level in the tube reactor is 26 cm, and Ca(OH) 2 The feeding flow rate of the slurry is 100 liters / minute, the area of the wire mesh at the bottom of the reactor is 5 square meters, and the wire mesh is a 200-mesh stainless steel wire mesh.

[0033] CO 2 The mixed gas flow rate is 250 l / min, CO 2 The mixed gas contains 25% CO 2 , the pH of the reactor outlet slurry is 6.9, and the slurry that goes out of the reactor is sent...

Embodiment 2

[0039] Adding Ca(OH) with a weight concentration of 10% in a jacketed reactor of 15 cubic meters 2 3 tons of slurry, then add 7 tons of water to dilute to Ca(OH) with a weight concentration of 3.0% 2 Slurry, add 1200kgMgCl again wherein 2 ·6H 2 O, stir to dissolve completely, pass steam into the reactor jacket, and heat the slurry to 90°C. Two 15 cubic meter reactors take turns to continuously feed the reactor.

[0040] The heated slurry is pumped into a tank reactor with a length of 80 meters and a section of 50×50 cm. The liquid level in the tubular reactor is 40 cm, and Ca(OH) 2 The feeding flow rate of the slurry is 150 liters / minute, the area of the wire mesh at the bottom of the reactor is 8 square meters, and the wire mesh is a 325-mesh stainless steel wire mesh. CO 2 The mixed gas flow rate is 320 l / min, CO 2 The mixed gas contains 22% CO 2 , the reactor outlet slurry pH is 7.0, the slurry out of the reactor is sent to the vacuum drum filter for filtration and...

Embodiment 3

[0046] Adding Ca(OH) with a weight concentration of 10% in a jacketed reactor of 15 cubic meters 2 1 ton of slurry, then add 10 tons of water to dilute to 1.0% Ca(OH) by weight 2 Slurry, add 300kgMgCl again wherein 2 ·6H 2 O, stir to make it dissolve completely, pass steam into the reactor jacket, and heat the slurry to 95°C. Two 15 cubic meter reactors take turns to continuously feed the reactor.

[0047] The heated slurry is pumped into a long 100 meter oval reactor, the major axis of the ellipse is 80cm and the minor axis is 40cm, the liquid level in the oval reactor is 55cm, Ca(OH) 2 The feeding flow rate of the slurry is 210 liters / minute, the area of the wire mesh at the bottom of the reactor is 7.5 square meters, and the wire mesh is 800 mesh stainless steel wire mesh. CO 2 The mixed gas flow rate is 500 l / min, CO 2 The mixed gas contains 24% CO 2 , the reactor outlet slurry pH is 7.0, the slurry out of the reactor is sent to the vacuum drum filter for filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com