Low NOx oil gun device heated by backheating

A regenerative heating and oil gun technology, which is used in lighting and heating equipment, solid fuel combustion, combustion and ignition, etc. , easy maintenance and maintenance, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

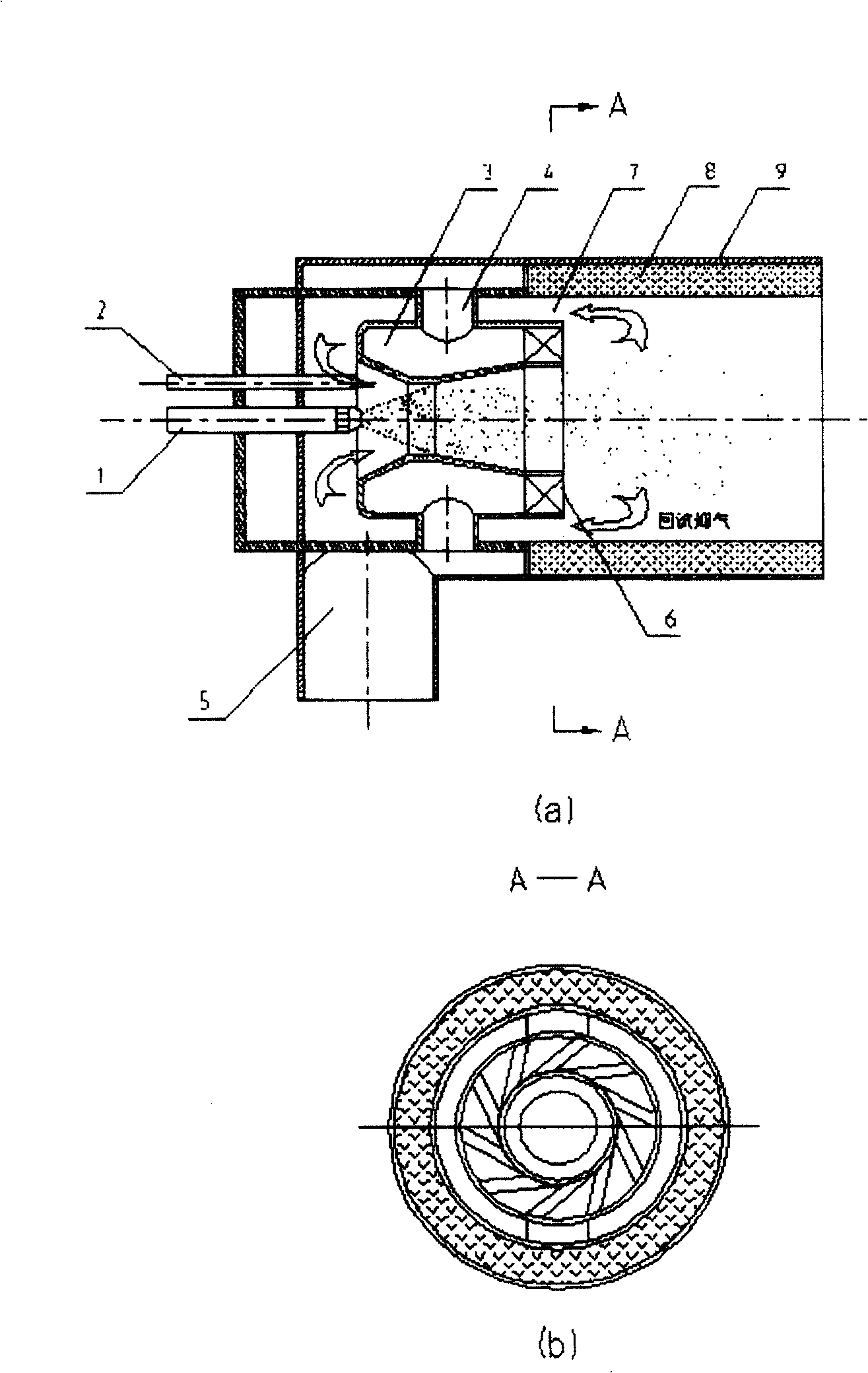

[0018] Such as figure 1 As shown, the low NOx oil gun device utilizing regenerative heating includes a micro-oil oil gun 1, a high-energy ignition gun 2, a Venturi air duct 3, a Venturi air inlet pipe 4, a total air inlet pipe 5, a cyclone 6, a return Hot channel 7, ceramic combustion chamber 8 and shell 9, ceramic combustion chamber 8, swirler 6 are arranged inside the shell 9, swirler 6 is connected with venturi air duct 3, and venturi air duct 3 is provided with venturi The air inlet pipe 4 is connected with the main air inlet pipe 5 on the shell 9, and the inlet end of the Venturi air duct 3 is provided with a micro-oil gun 1 and a high-energy ignition gun 2.

[0019] The return flow of hot flue gas produced by fuel combustion in the oil combustion chamber at the rear end of the swirler 6 is 2%-10% of the total flue gas volume. After the reflux hot flue gas and oil mist are mixed, the mixing temperature reaches 200°C-350°C. The ratio of the throat area of the Venturi a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com