Hydrazine hydrate byproduct 5% salt water processing and reclamation method

A technology of hydrazine hydrate and brine, applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of waste of water resources, increase of treatment costs, environmental impact, etc., to reduce salt consumption, The effect of reducing waste and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

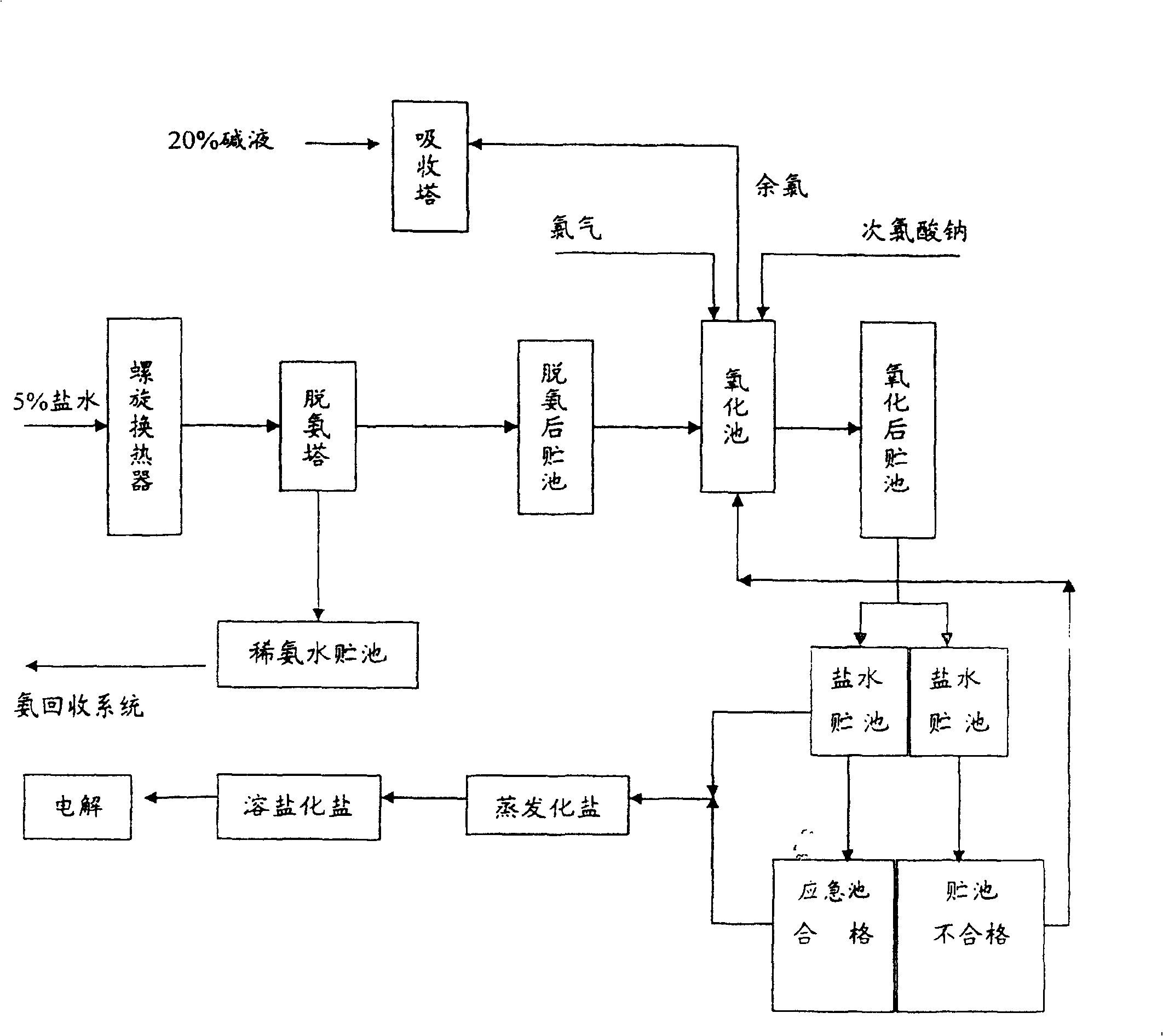

[0023] The hydrazine hydrate by-product 5% salt water treatment and reuse method is to process the hydrazine hydrate by-product 5% salt water according to the following steps:

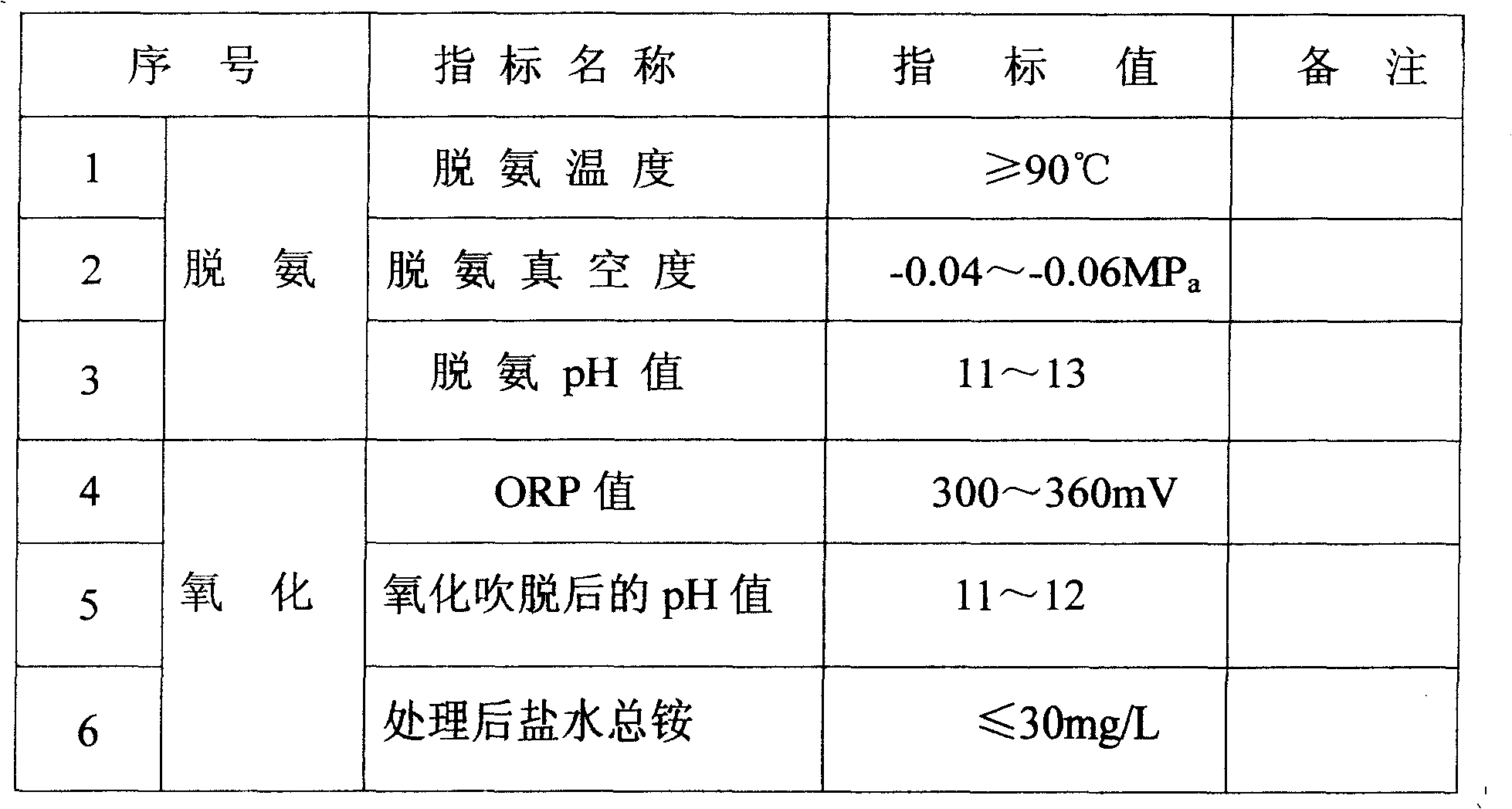

[0024] 1. Deamination

[0025] In a vacuum state, the ammonia in brine is removed from the waste brine and condensed into dilute ammonia water as the temperature rises, the solubility decreases, and the temperature is controlled at 90-95°C, the pH value is 11-13, and the vacuum degree is -0.04 ~-0.06MP a . Send 5% brine to the spiral heat exchanger to heat up to 90-95°C, and then send it to the deammonization tower. If the temperature is less than 90°C, steam should be turned on, and the temperature of the brine will reach 90-95°C through the steam-water mixer, and then pass through the rotor The flow meter enters the deamination tower, and the removed ammonia gas is condensed into dilute ammonia water through the ammonia condenser, pumped into the dilute ammonia water pool by 2# ammonia water pump, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com