Method for preparing aluminium-carbon-dichromium block material

A block material, aluminum carbon dichromium technology, applied in the field of preparation of aluminum carbon dichromium bulk materials, can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

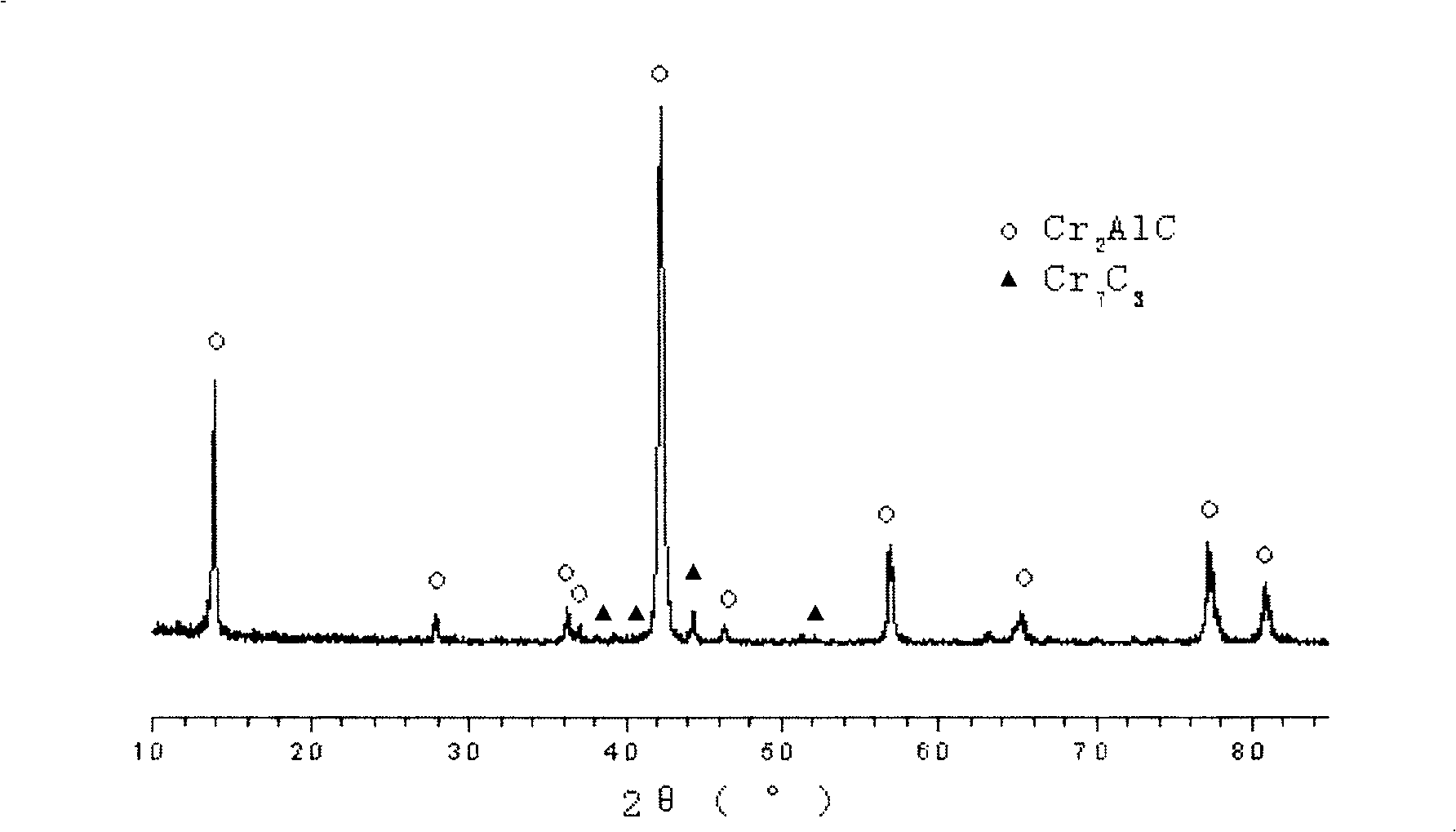

[0022] The raw materials are chromium powder (30μm, 99.95%), aluminum powder (100μm, 99.95%) and carbon powder (1.5μm, 99%). Weigh according to the molar ratio of Cr:Al:C=2:1.1:1, and ball mill for 24 hours, and the obtained slurry is dried to obtain uniformly mixed powder. The powder was pressed into a disc, placed in a graphite mold coated with BN, first vacuumed, and then flowed with Ar protection gas, and hot-pressed at 1400 ° C for 2 hours at a pressure of 25 MPa. After the sample is cooled and taken out, it is processed by a grinding machine and a polishing machine to obtain Cr 2 AlC blocks. The XRD of the material is shown in Figure (1), and the Cr2AlC phase content is 94wt%. The bulk density is 5.20g / cm 3 .

Embodiment 2

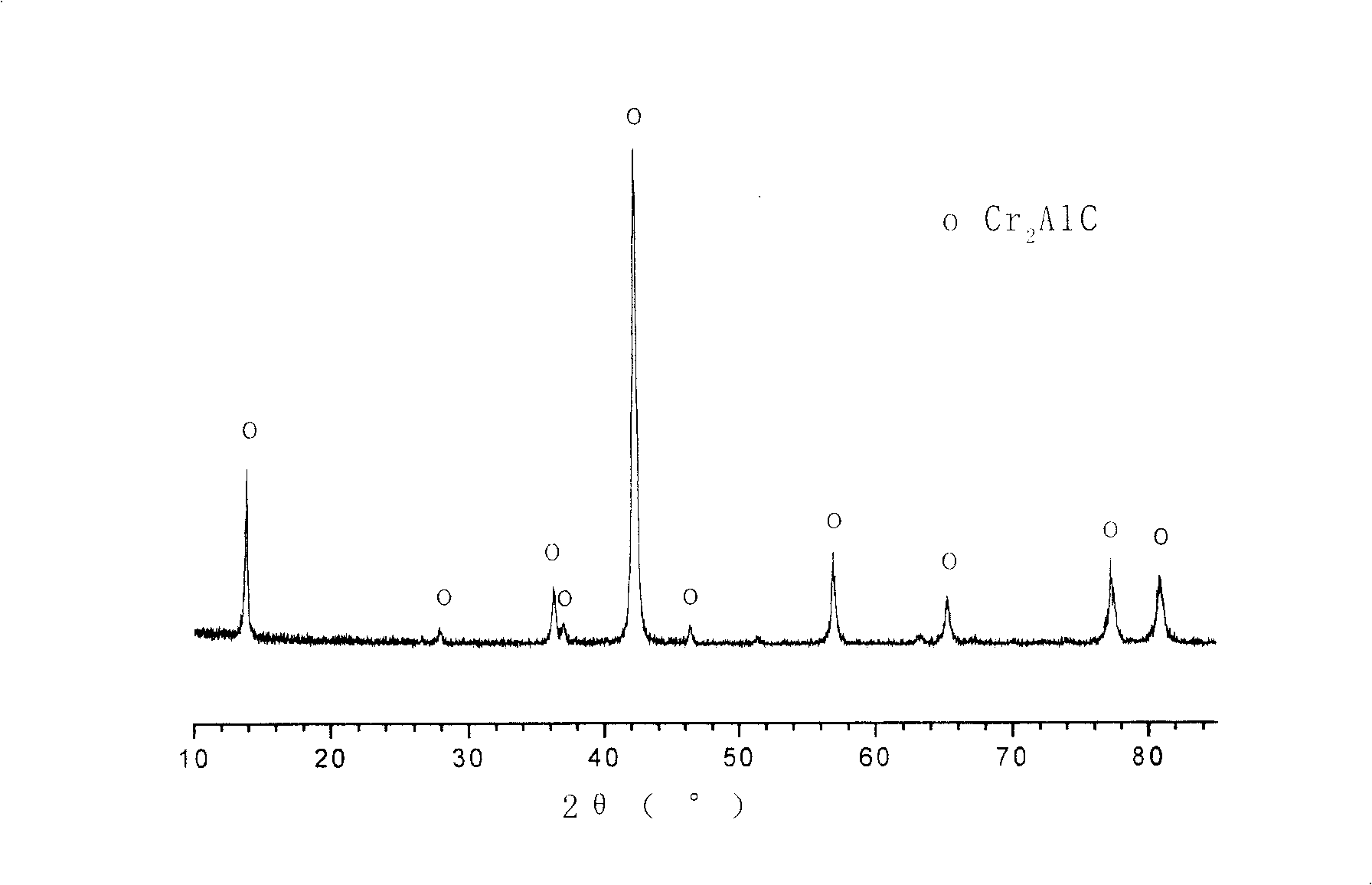

[0024] The raw materials are chromium powder (30μm, 99.95%), aluminum powder (100μm, 99.95%) and carbon powder (1.5μm, 99%). Weigh according to the molar ratio of Cr:Al:C=2:1.2:1, and ball mill for 24 hours. After the obtained slurry is dried, a uniformly mixed powder is obtained. The powder is pressed into a disc and placed on the surface to coat BN In the graphite mould, vacuumize first, then flow Ar protective gas, and press at 1450°C for 1 hour at a pressure of 20MPa. After the sample is cooled and taken out, it is processed by a grinding machine and a polishing machine to obtain Cr 2 AlC blocks. The XRD of the material is shown in Figure (2), Cr 2 The AlC phase content is 99wt%. The bulk density is 5.12g / cm 3 .

Embodiment 3

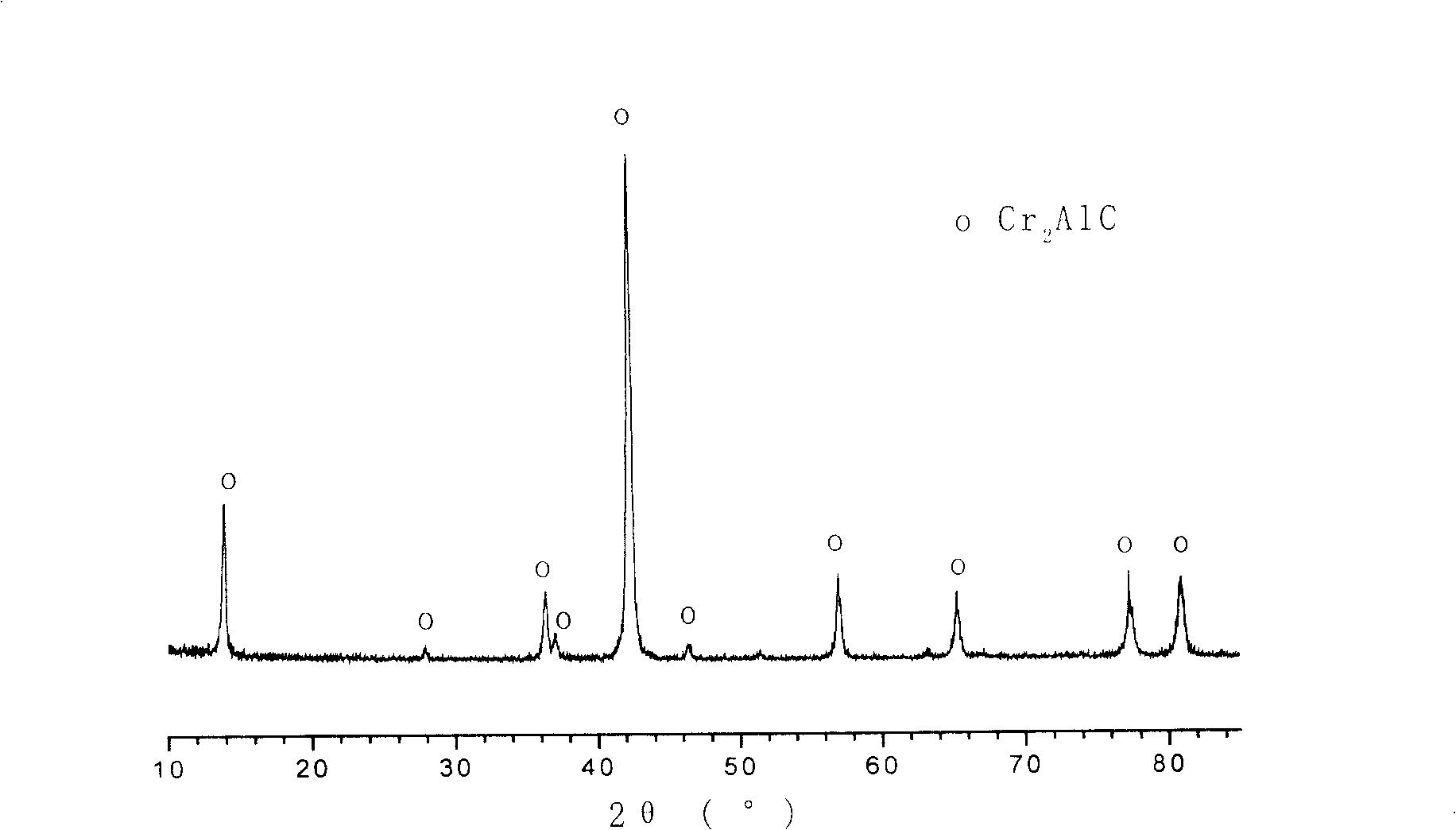

[0026]The raw materials are chromium powder (30μm, 99.95%), aluminum powder (100μm, 99.95%) and carbon powder (1.5μm, 99%). Weigh according to the molar ratio of Cr:Al:C=2:1.4:1, and ball mill for 24 hours, and the obtained slurry is dried to obtain uniformly mixed powder. Press the powder into a disc, place it in a graphite mold coated with BN, first evacuate it, then pass it into a flowing Ar protective gas, and heat press at 1350 °C with a pressure of 20 MPa for 1 hour. After the sample is cooled and taken out, it is processed by a grinding machine and a polishing machine to obtain Cr 2 AlC blocks. The XRD of the material is shown in Figure (3), Cr 2 The AlC phase content is 99wt%. The bulk density is 5.09g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com