Mechanical corrector for T-shape steel member bending deformation

A bending deformation, T-shaped steel technology, applied in the field of steel structure processing equipment, can solve the problems of low correction efficiency and high correction cost of correction equipment, and achieve the effects of saving correction cost, improving correction efficiency and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

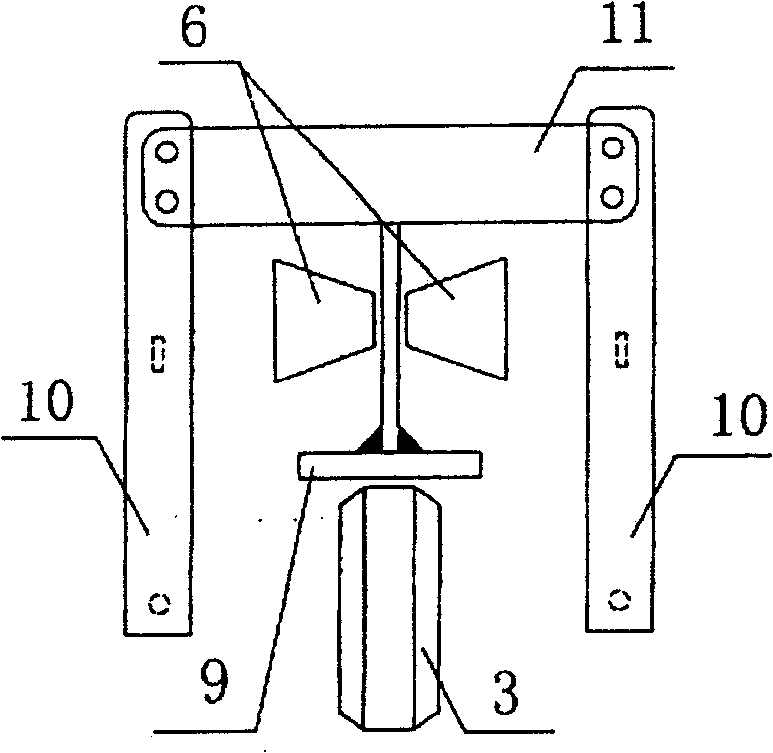

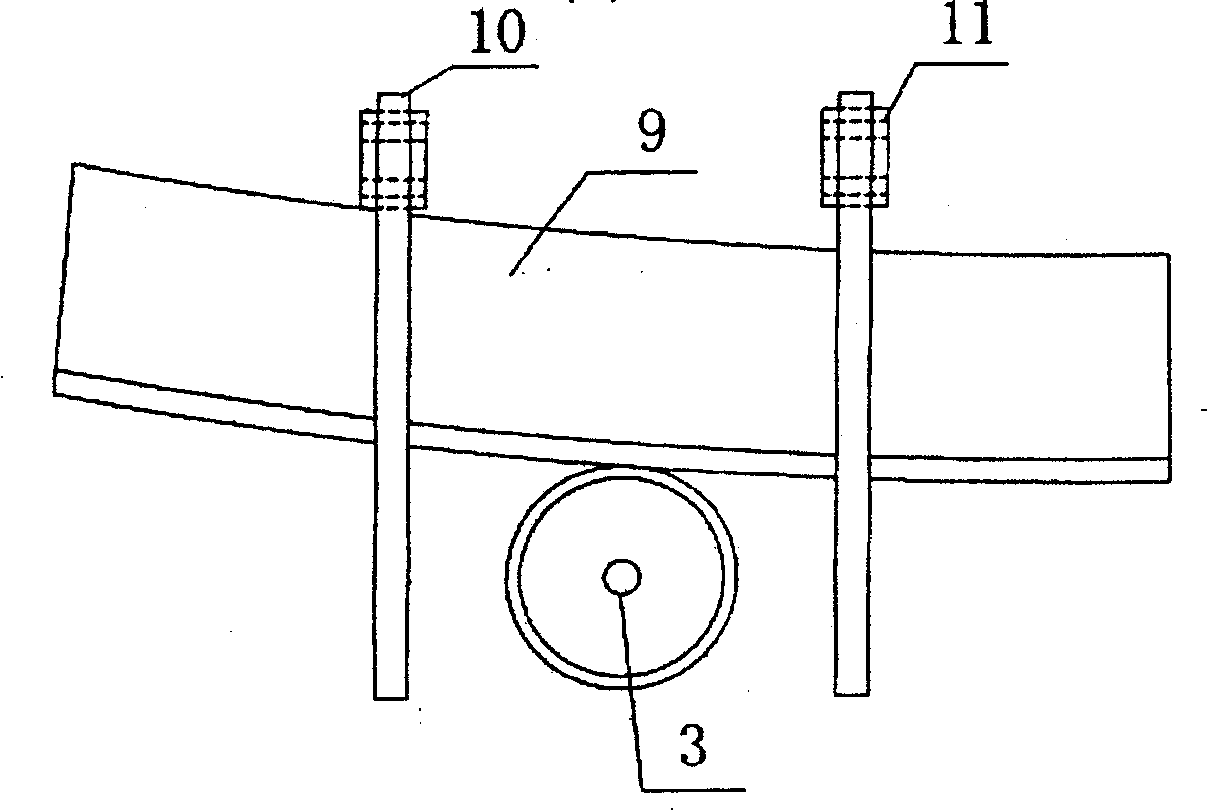

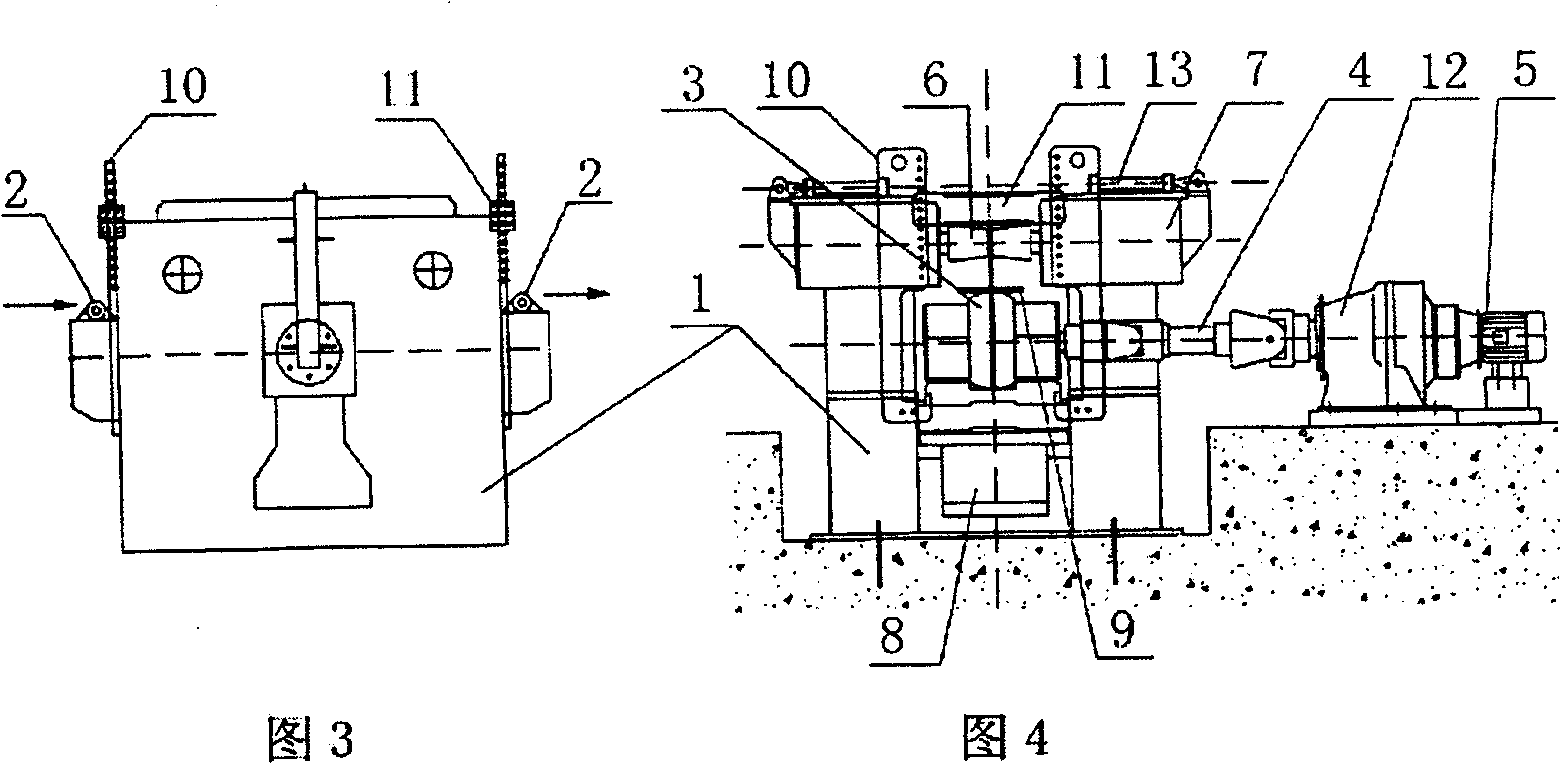

[0025] Examples see figure 1 -4. The present invention is a mechanical correction device for bending deformation of a T-shaped steel member, which includes an H-shaped frame 1, and a roller table 2 supporting a steel member 9 is installed from the input end to the output end of the frame, and in the middle of the frame , is provided with the driving wheel 3 that links to each other with the hydraulic device 8 at the flush position above the roller table, and the driving wheel shaft is also connected with the motor 5 through the universal coupling 4 and the speed reducer 12.

[0026] A pair of straightening wheels 6 are arranged on both sides above the driving wheel, and the two ends of the straightening wheel shaft are connected with the axle boxes 7 and hydraulic cylinders 13 on both sides.

[0027] A pair of vertical plates 10 are respectively fixedly connected to both sides of the input end and the output end of the frame, and a horizontal plate 11 is connected between each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com