Liquid hydrocarbon evaporation inhibitor

A liquid hydrocarbon and spreading agent technology, applied in the field of liquid hydrocarbon vapor suppressor and its preparation, can solve the problems of limited use and high density, and achieve the effect of suppressing evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

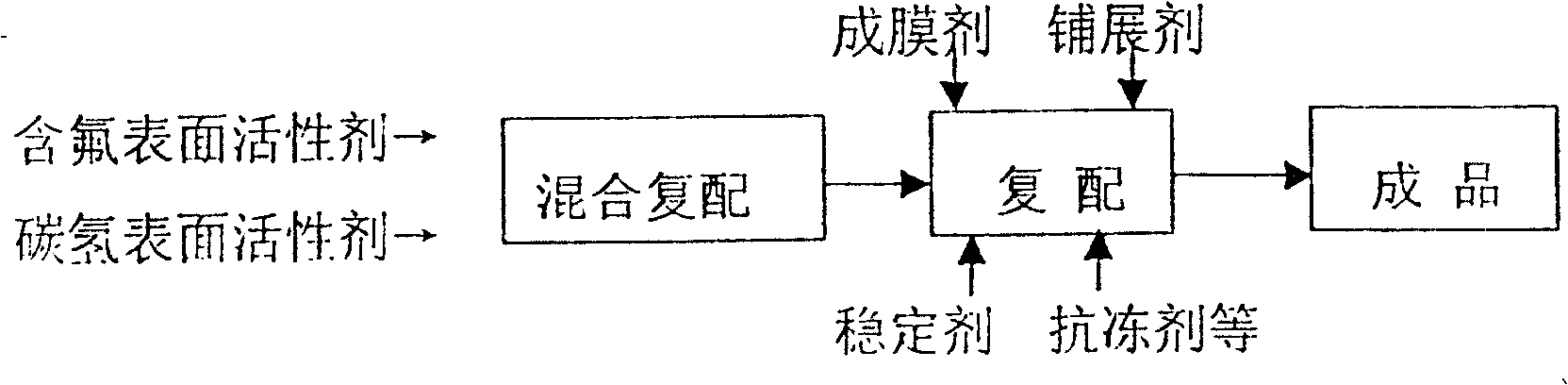

Method used

Image

Examples

Embodiment 1

[0035] Formula: 10kg of alkylammonium bromide, 10kg of FC-80, 10kg of hexanol, 1kg of cetyl alcohol, 0.08kg of polysaccharide, 20kg of urea, 2kg of salt, and 46.92kg of water.

[0036] First, add alkylammonium bromide and FC-80 to mix with water, then add hexanol, cetyl alcohol, polysaccharide, urea, and salt to mix, and mix well to get the finished product.

Embodiment 2

[0038] Formula: 5kg of alkylammonium bromide, 3kg of DF-134, 1kg of hexanol, 1.5kg of cetyl alcohol, 10kg of isopropanol, 0.4kg of polysaccharide, 20kg of urea, 1kg of table salt, and 46.92kg of water.

[0039] First, add alkylammonium bromide and DF-134 to mix with water, then add hexanol, cetyl alcohol, isopropanol, polysaccharide, urea, and salt to mix, and mix well to get the finished product.

Embodiment 3

[0041] Formula: Amphoteric fluorosurfactant 2kg, DF-134 3kg, silicone surfactant 1.8kg, K 12 2kg, diethylene glycol butyl ether 10kg, isopropanol 6kg, gasoline 75.2kg.

[0042] First mix amphoteric fluorosurfactant, DF-134, silicone surfactant and gasoline, then add K 12 , diethylene glycol butyl ether, and isopropanol are mixed, and the finished product is obtained after stirring evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com