Electronic pattern card

A patterned board and electronic technology, applied in the field of devices for controlling needle selection of jacquard machines, can solve the problems of electronic pattern board production, debugging, installation and maintenance difficulties, affecting the service life of electromagnets, increasing the current of working coils, etc. Competitiveness, cardboard savings, faster updates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An example:

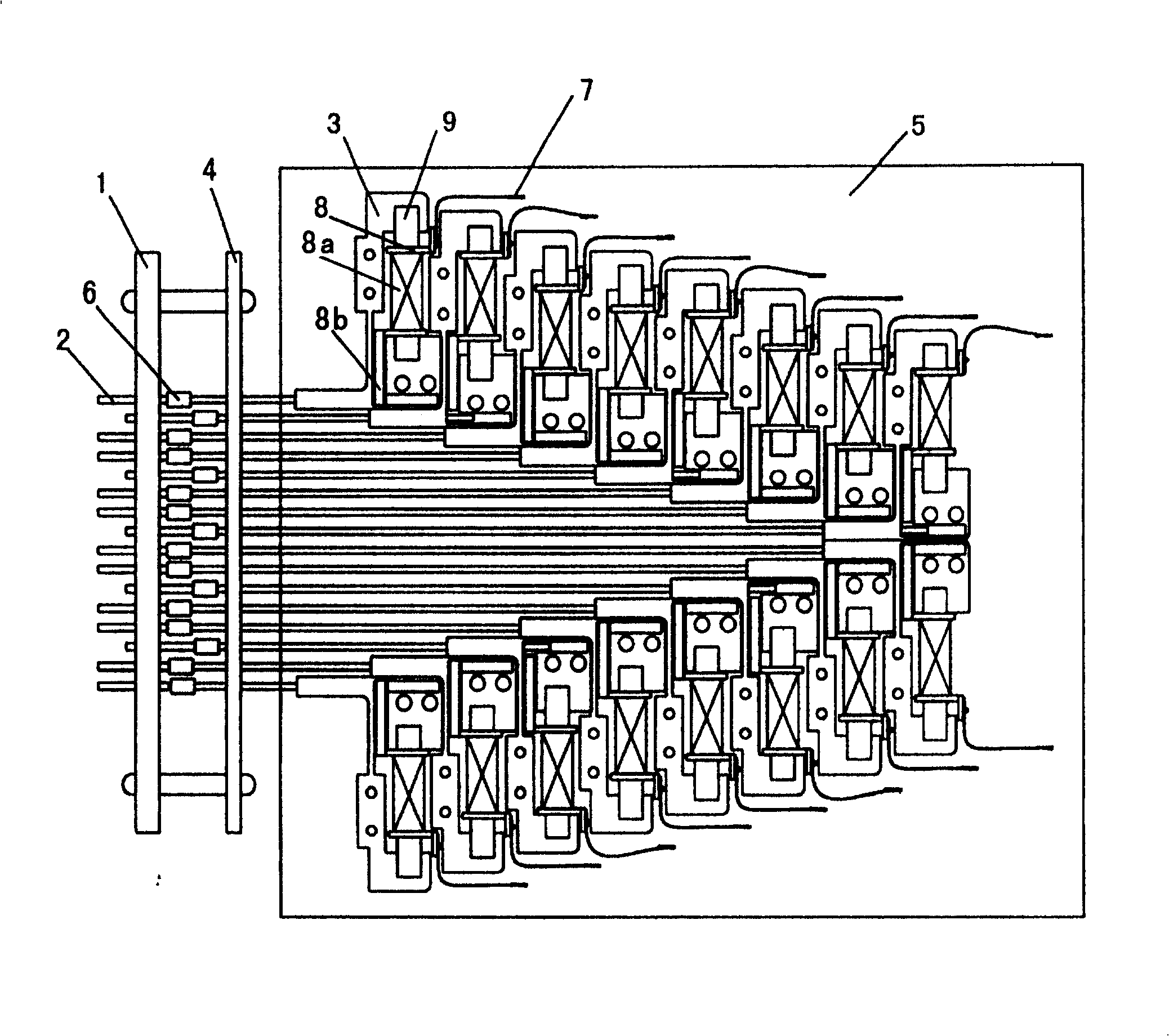

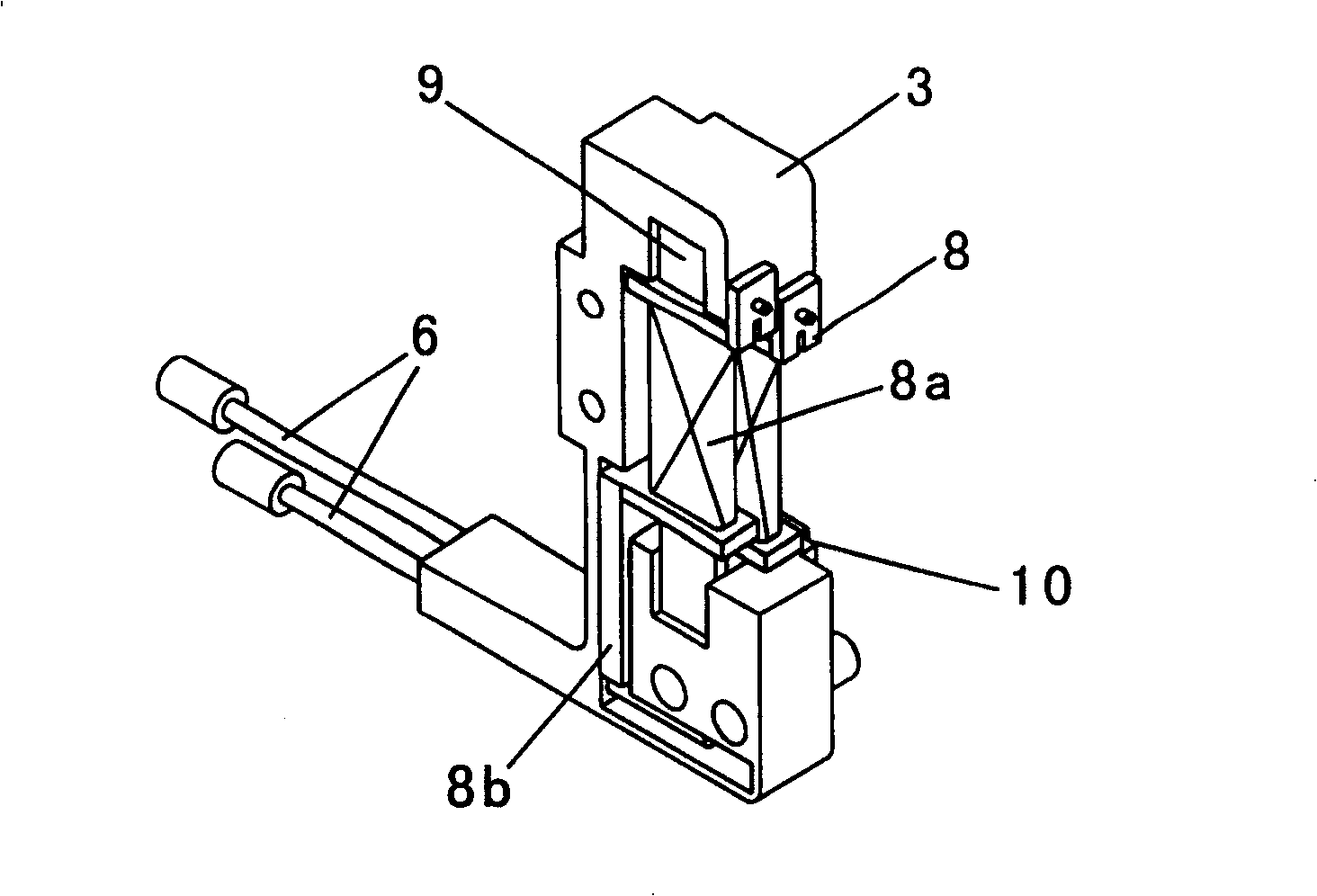

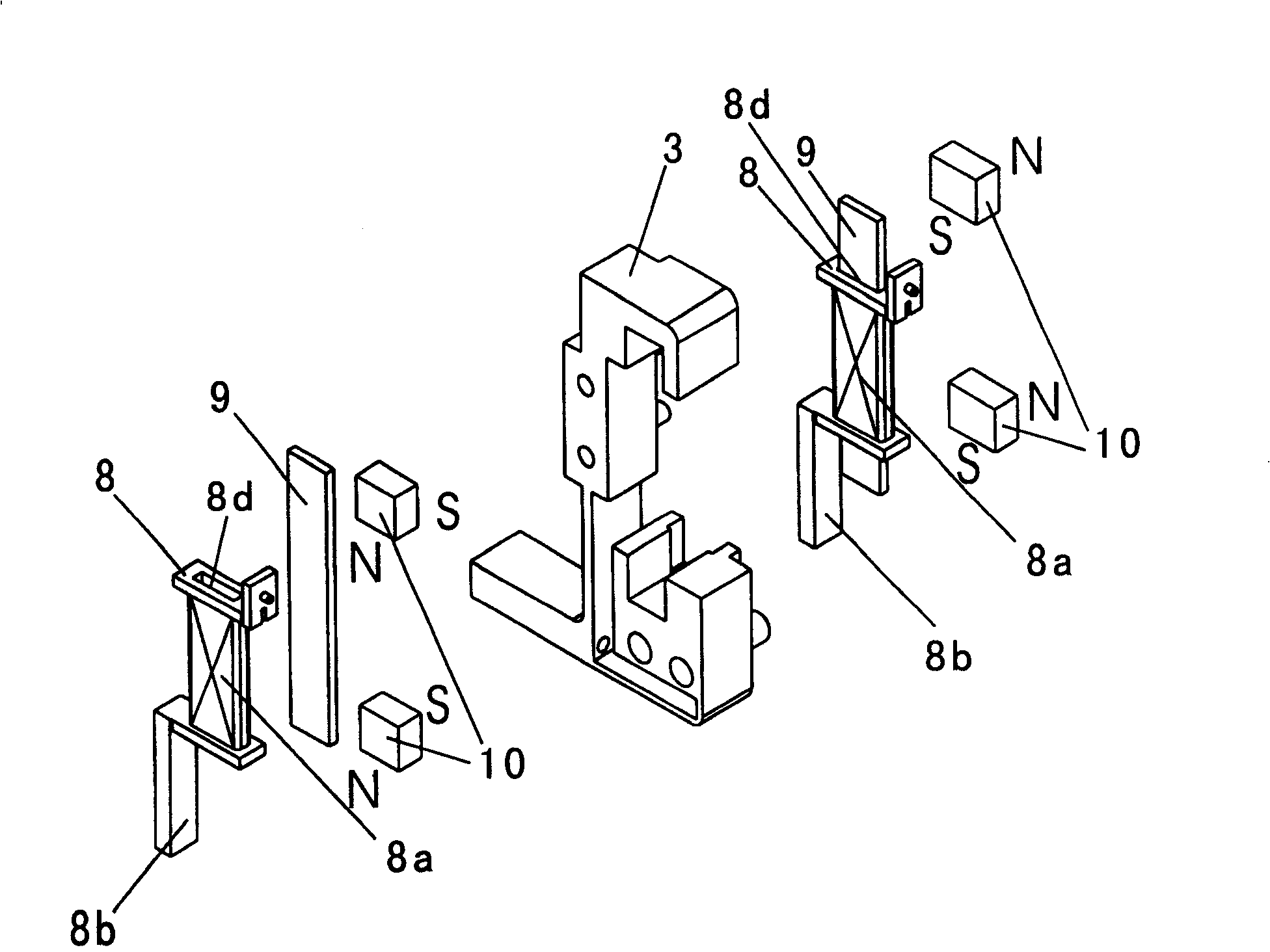

[0022] An electronic pattern board with a total of 1216 needles. It is composed of 38 solenoid valve plates. Each solenoid valve plate is distributed with 16 solenoid valves in a ladder shape. It adopts a composite excitation system. Each solenoid valve is equipped with two coils and two solenoid valves. Coil bobbin, two strip iron cores, four permanent magnets, two push pins, each solenoid valve plate corresponds to 32 horizontal pins, the distance between the needles is 4mm, the solenoid valve plates are stacked on top of each other, the solenoid valve substrate 5 It is a circuit board with a specification of 18X17cm, on which there is a flexible circuit 7 connected to the drive circuit of the computer and connected to the coil 8a. There are 16 flexible circuits on each electromagnetic valve board. One end of the flexible circuit 7 is fixed on the substrate, and the other end is fixed on the wire. On the terminal 8c on the coil bobbin; the solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com