Memory device and method for fabricating the same

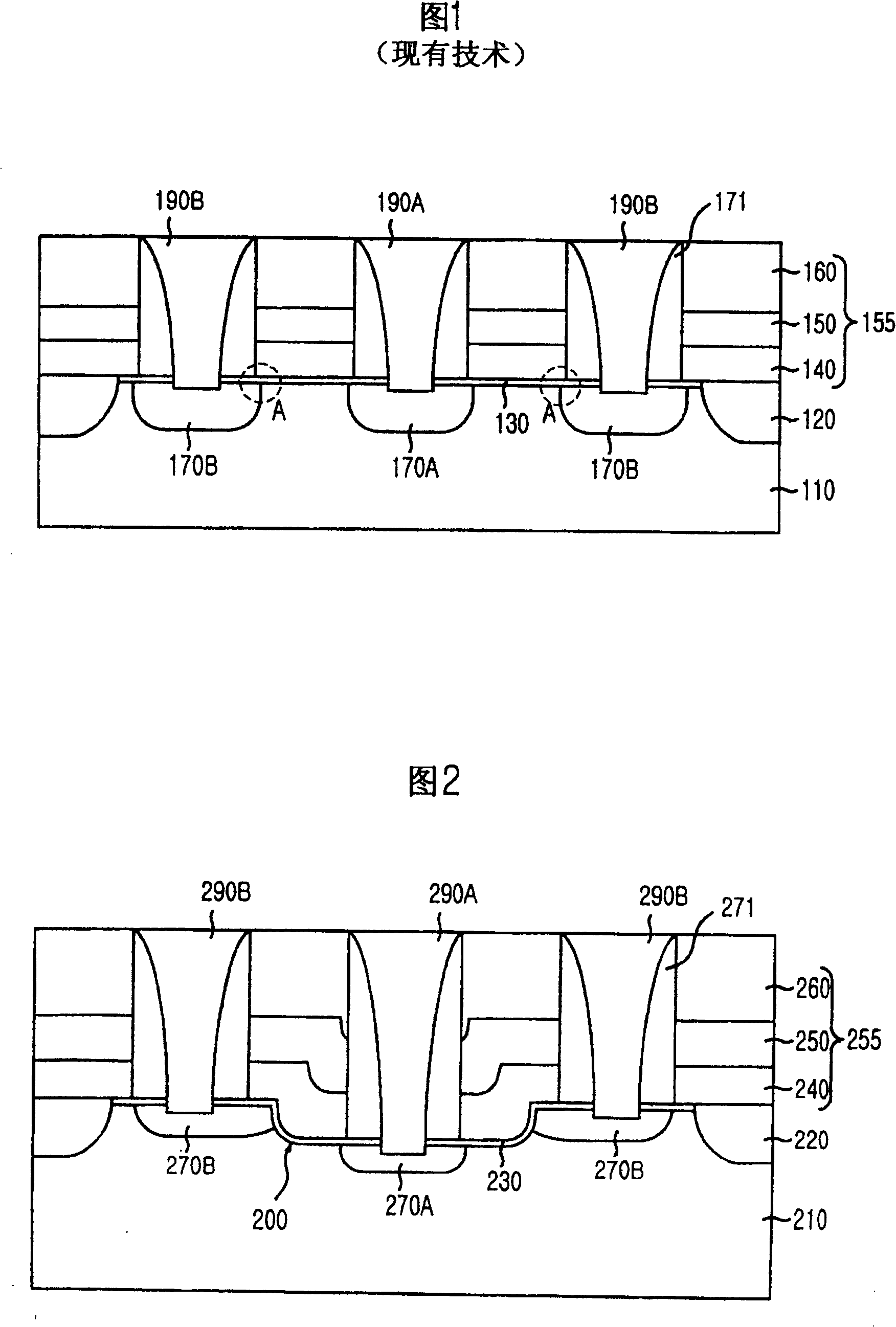

A technology for storage devices and storage nodes, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve problems such as increased junction leakage current, reduced data retention time, and degradation of recovery characteristics of storage devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

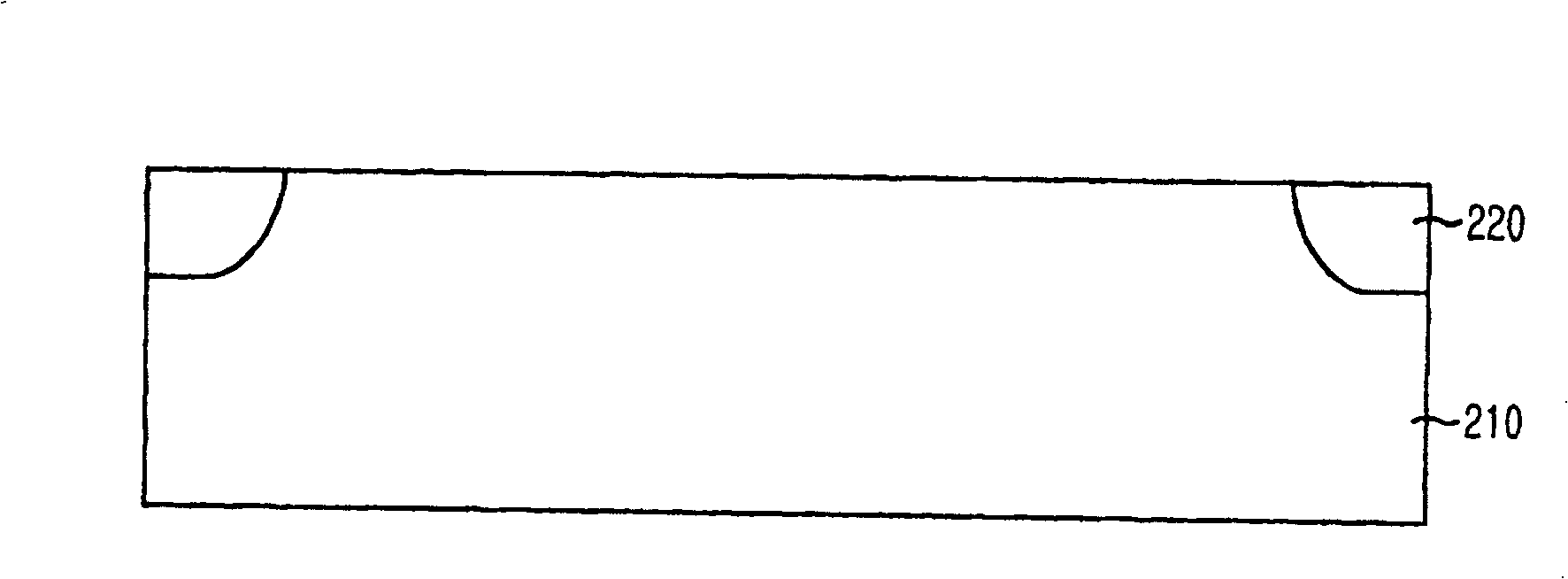

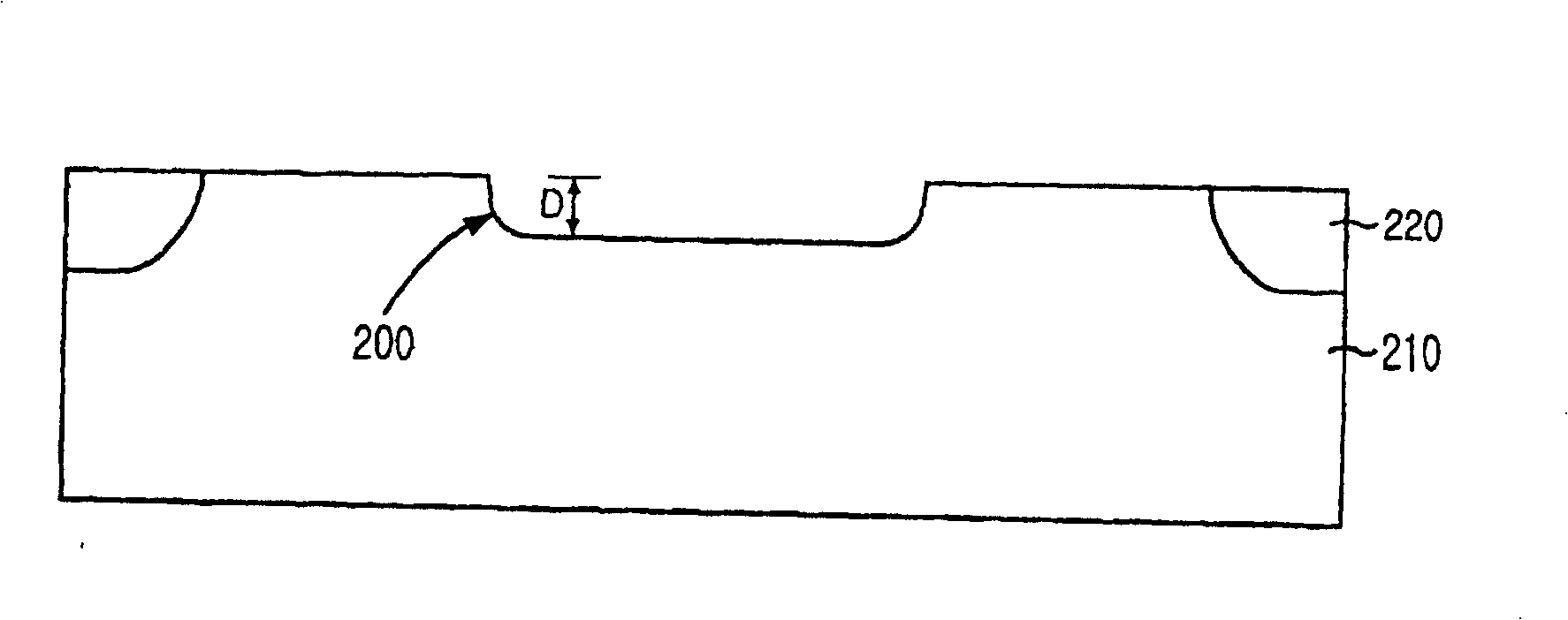

[0037] According to the first embodiment of the present invention, the first contact junction 270A connected to the bit line is formed in the substrate in the trench 200, so the sidewall of the trench 200 constitutes the channel region of the transistor in the cell region.

[0038] Figure 4 A cross-sectional view illustrating a structure of a memory device according to a second embodiment of the present invention.

[0039] Here, the memory device according to the second embodiment includes the same configuration elements described in FIG. 2, and therefore, detailed descriptions about such configuration elements will be omitted. The memory device manufactured according to the second embodiment differs from the memory device manufactured according to the first embodiment in that the side wall B of the trench 300 is formed perpendicular to the surface of the recessed portion of the substrate 310 , and the plurality of gate structures 355, the first contact junction 370A and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com