Chip fixing device for finding chip defect by luminous microscope

A fixed device, a technology under the microscope, applied in the direction of optical testing flaws/defects, measuring leads/probes, etc., can solve the problems of waste of cost, poor versatility, difficult to control, etc., to achieve good applicability, stable center of gravity, and avoid clutter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below through specific examples.

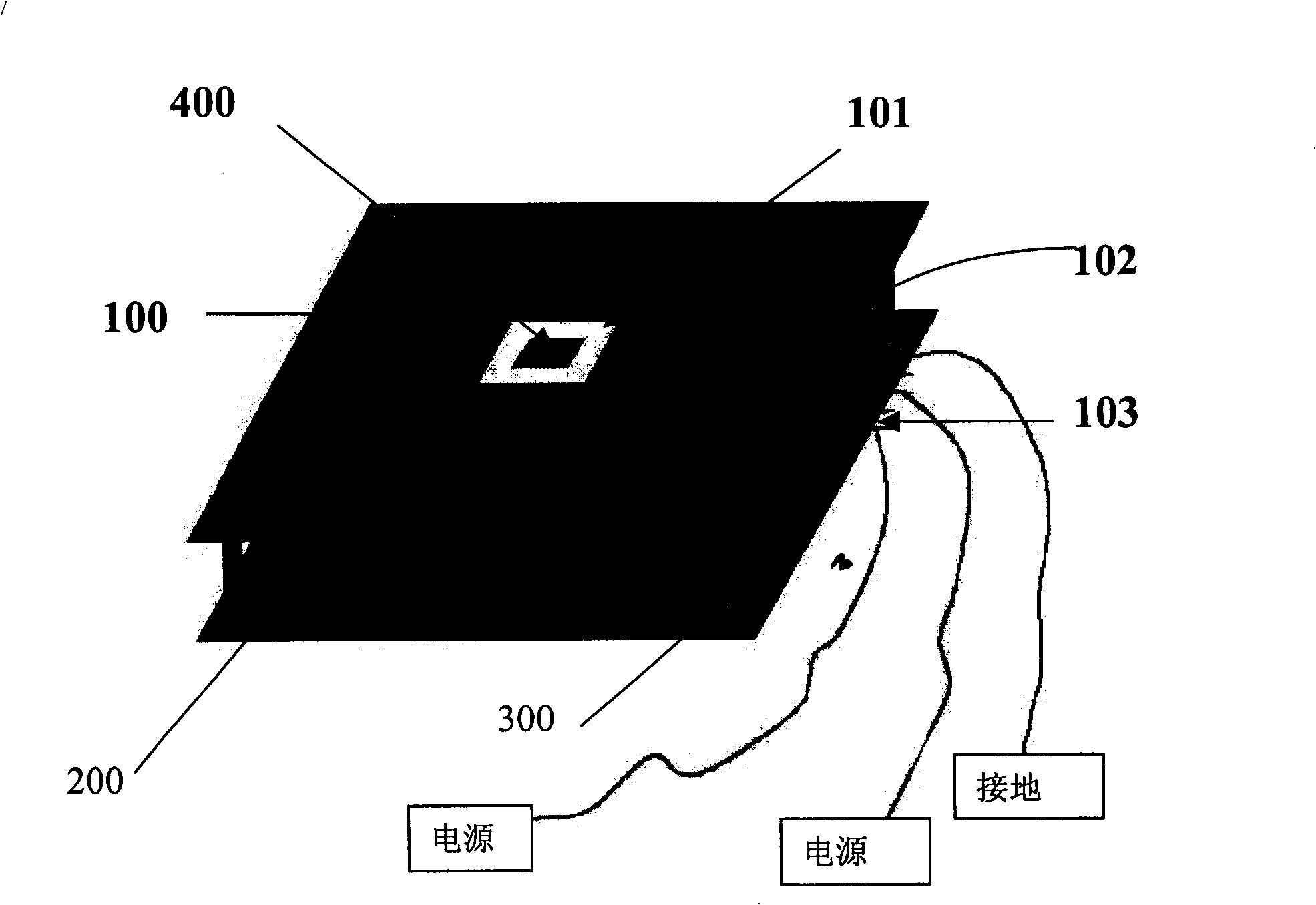

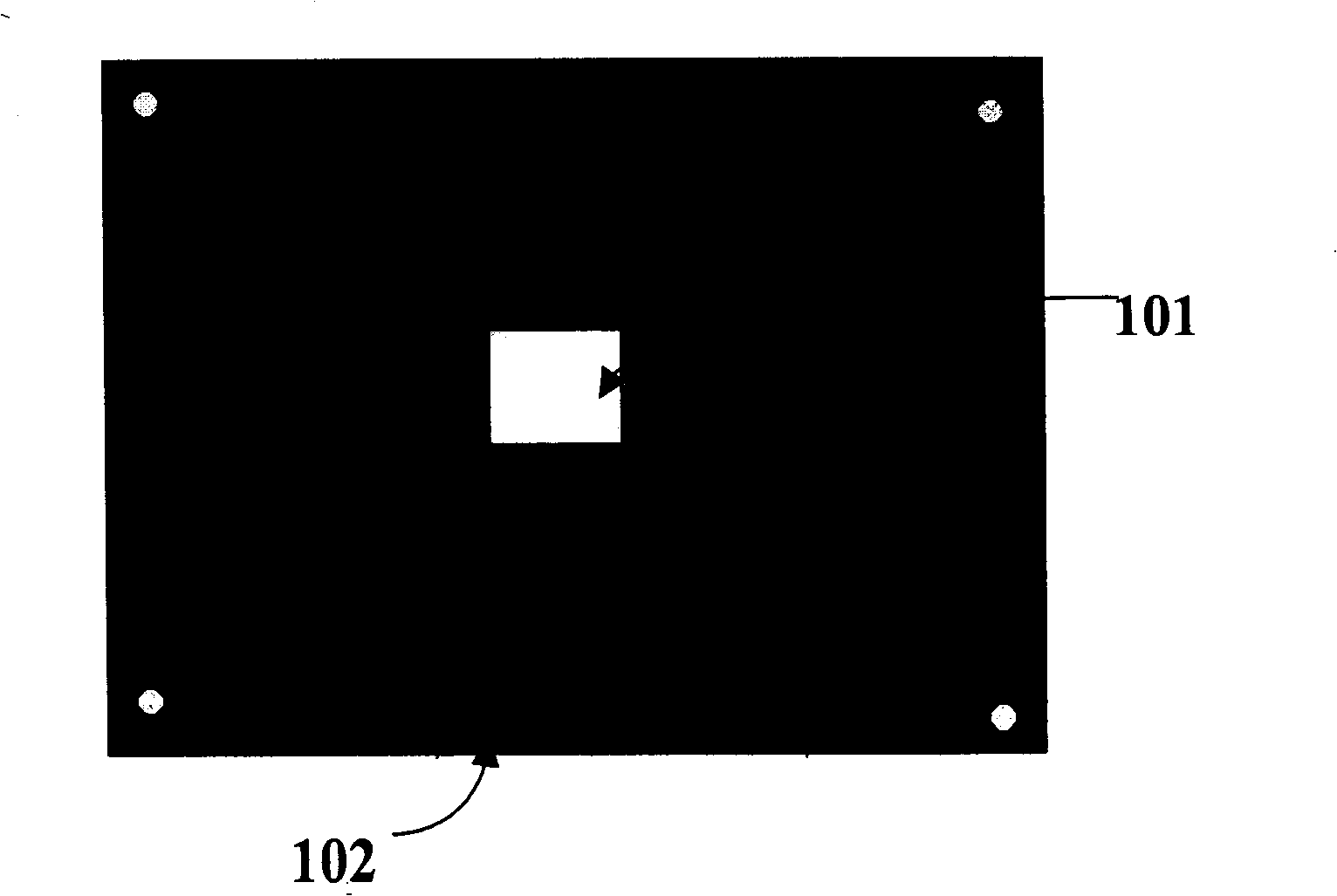

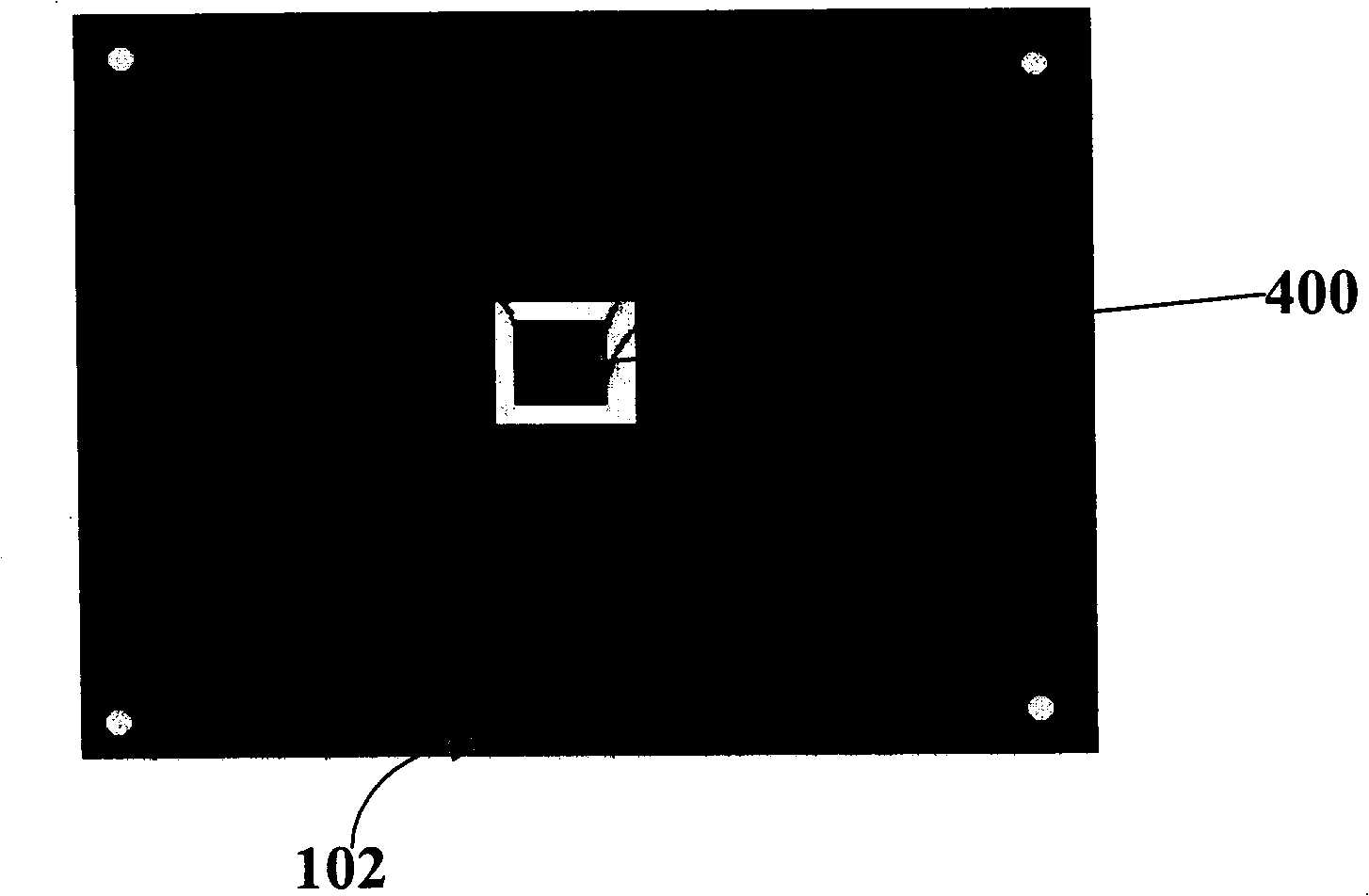

[0012] please see figure 1 As shown, it is a schematic diagram of the fixing device of the present invention. In this embodiment, the fixing device is a structure comprising upper and lower layers, the upper layer is a printed circuit board (PCB board) 100; the lower layer is a fixing plate 200 for fixing , made of heavier materials such as stainless steel, etc., so that the center of gravity of the fixing device remains relatively stable, and the chip can be stably presented under the lens of the light-emitting microscope during operation; and this two-layer structure makes it easy to The upper printed circuit board avoids the trouble of being entangled by electrical wires; the printed circuit board 100 and the fixing plate 200 are thus figure 1 The rectangle, also can be other shapes, is provided with support element 300 between the two, figure 1 The middle support element 300 is fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap