Overall plastic solar heat collector

A technology of solar thermal collector and heat exchange container, applied in the field of solar thermal collector, can solve the problems of high cost of solar thermal collector, need frequent maintenance, complicated welding process, etc. And the effect of low construction and installation cost and low maintenance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

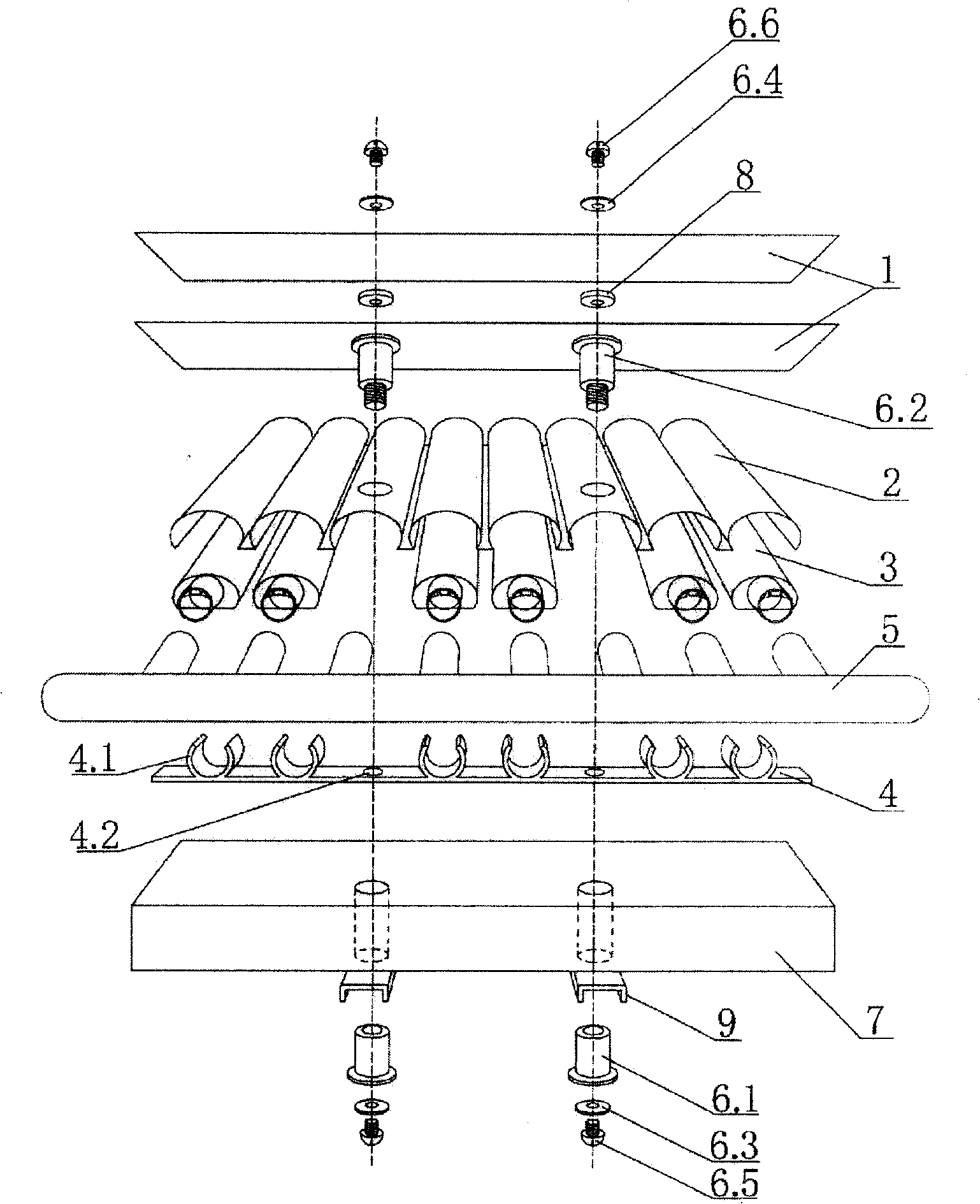

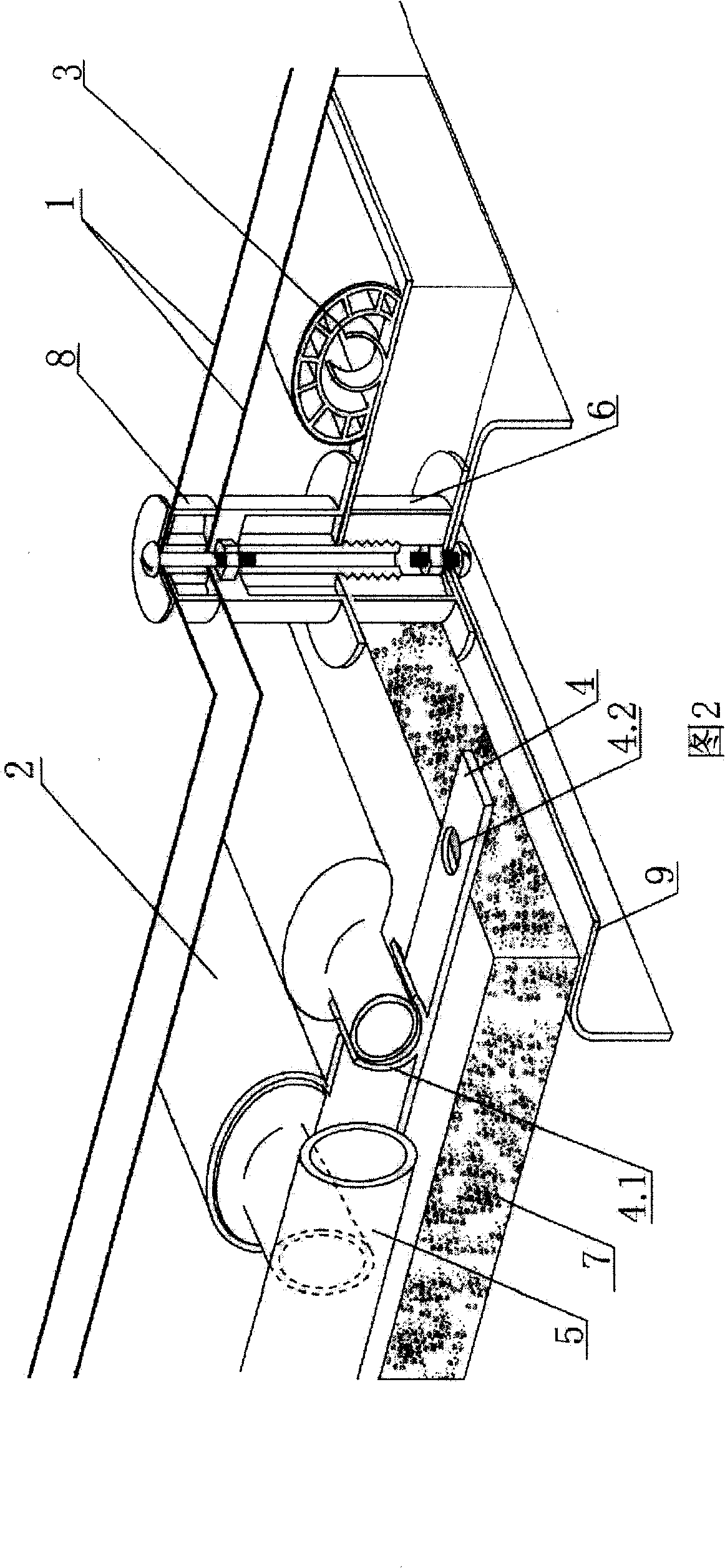

[0039] Examples see figure 1 , As shown in 2, this all-plastic solar collector is assembled by a shell, a heat-absorbing member, a heat exchange container, an insulation layer and a support body, wherein the shell, the heat absorption member, the heat exchange container and the insulation layer are rearward from the light-receiving surface Arranged in order. This all-plastic solar collector mainly includes a transparent cover plate, an ultra-thin heat-absorbing sheet, an ultra-thin heat exchange container, a plastic bracket, an insulation layer and a plastic composite pillar. The components are arranged in sequence from the light-receiving surface, and the plastic composite pillars connect the components in the arrangement direction as a whole, and are fixed on the structure to be placed.

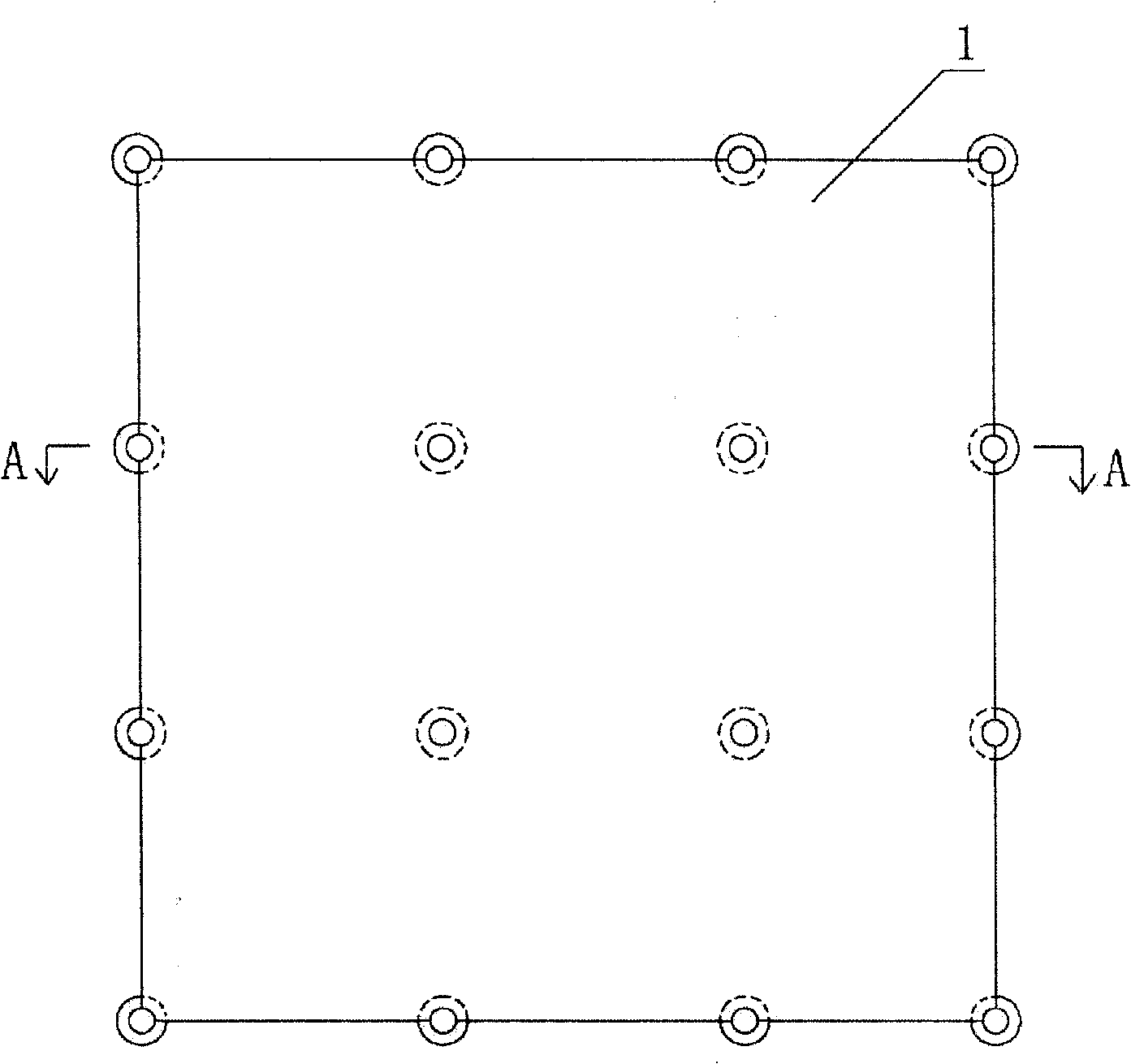

[0040] See Figure 1-4 , The housing 1 is a transparent cover plate supported by a gasket 8 and formed between double-layer ultra-thin plastic sheets, which has a certain rigidity and strength....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com