Technology for making diamond composite sheet drill bit body by hot press method and drill bit body

A technology for a diamond composite sheet and a drill bit body is applied in the field of manufacturing the drill bit body, which can solve the problems of low drill life, low machining accuracy, long machining cycle, etc., and achieves the effects of reliable diameter keeping performance, high welding strength, and short machining period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

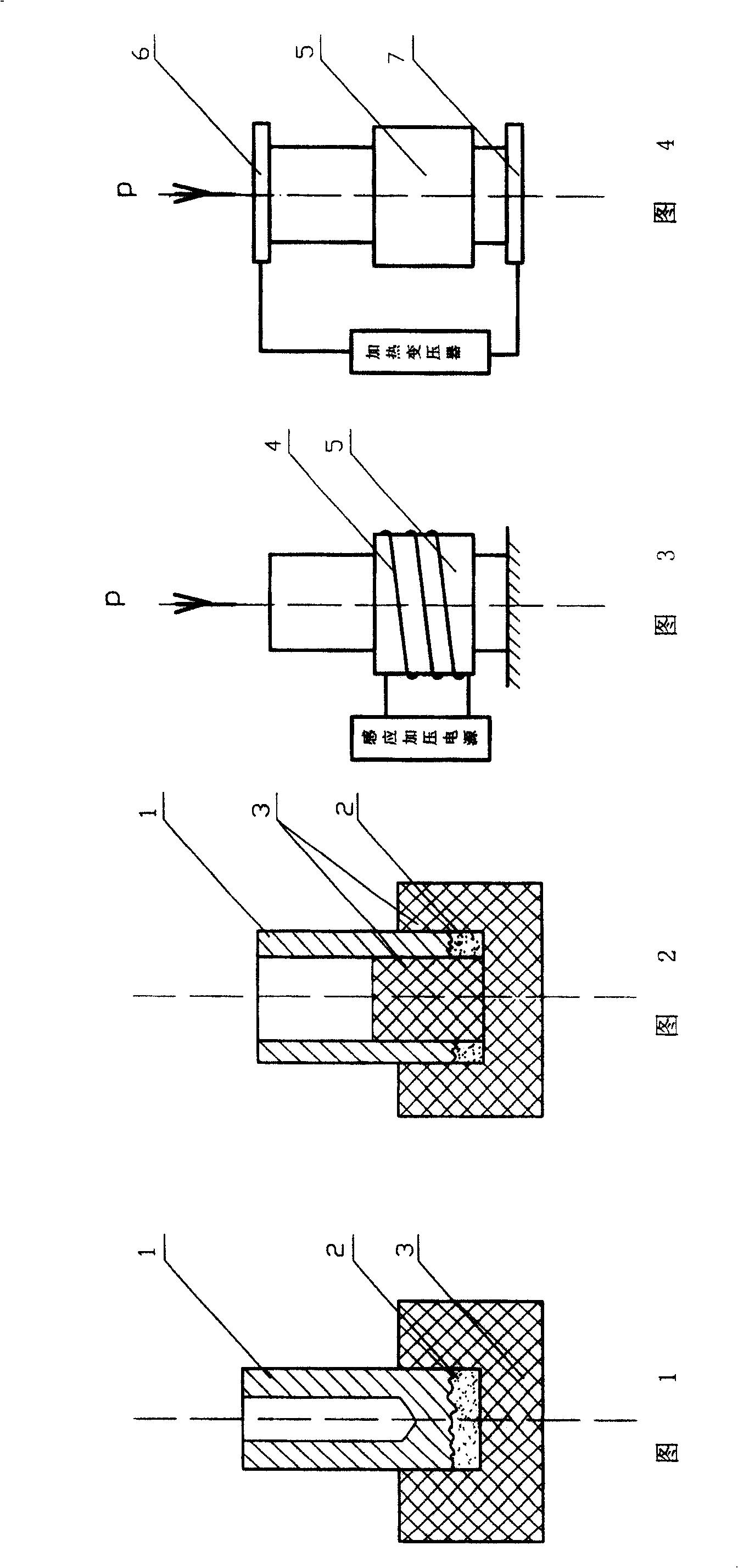

[0025] [Embodiment 1] of the present invention: φ94 mm hot-pressed centerless composite sheet drill body manufacturing process. See Figure 1, Figure 3, and Figure 4. In the figure: 1 is the steel matrix, 2 is the carcass material, 3 is the graphite mold, 4 is the induction coil, 5 is the mold assembly, 6 and 7 are the upper and lower electrode plates.

[0026] (1) Process the steel substrate and graphite mold according to the design drawings, and pass the inspection.

[0027] (2) Glue the gauge material (polycrystalline diamond or cemented carbide) on a specific position of the graphite mold, and place a graphite sheet on the reserved position of the composite sheet.

[0028] (3) According to the ratio of 25% tungsten carbide, 10% copper, 2% iron, 5% manganese, 3% nickel, 25% tin, 10% lead, 10% chromium and 10% cobalt, mix the carcass material and fully stir mix.

[0029] (4) Put the weighed carcass material into the graphite mold, and assemble the steel substrate in the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com