Narrow profile furrow opener capable of operating at high speed

A technology of openers and furrows, applied in the field of openers, can solve problems such as increased cost and maintenance, cannot be completely solved, and blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

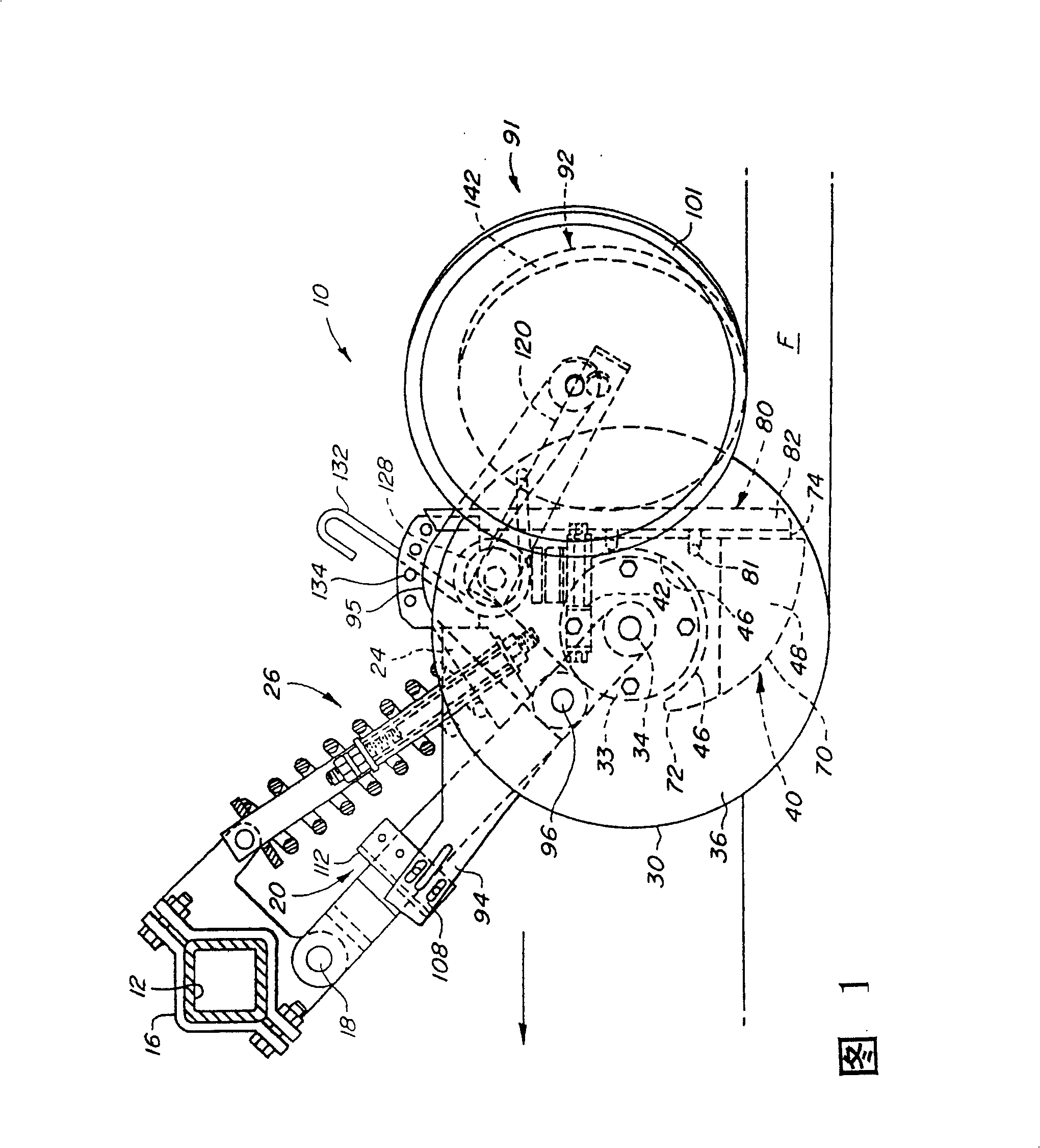

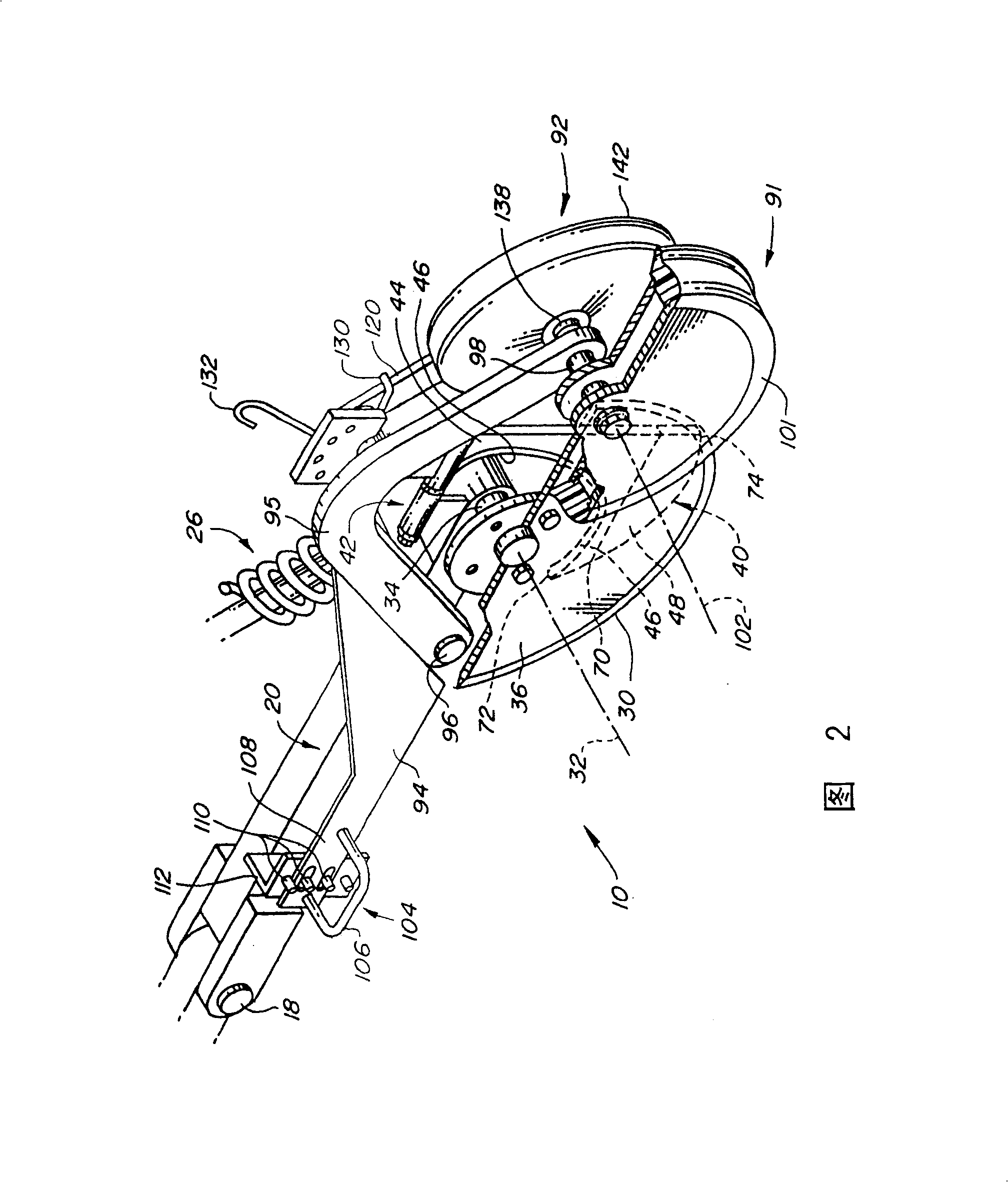

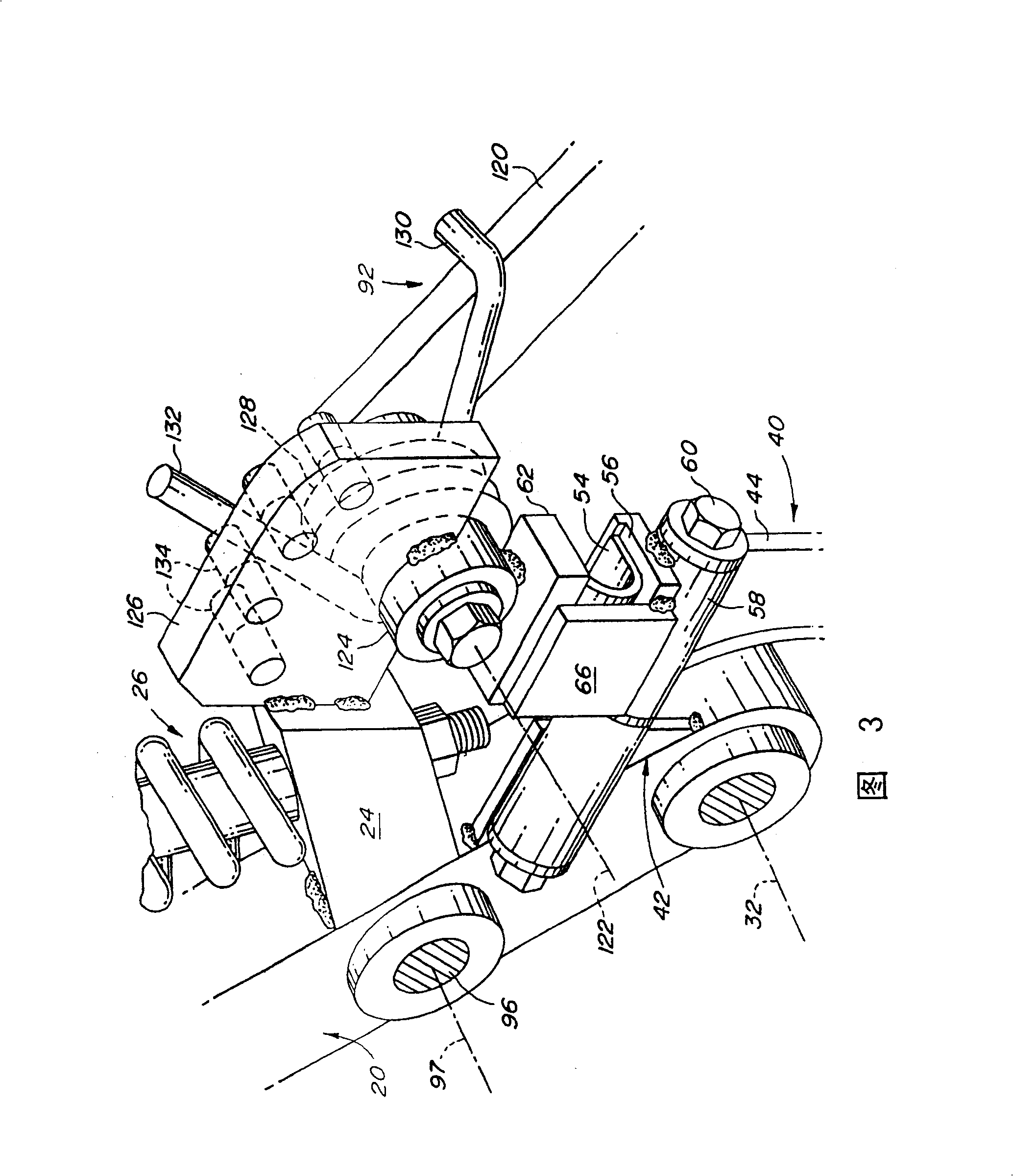

[0036] Referring now to FIG. 1 , there is shown an opener assembly 10 which is attached to a laterally extending frame tube or universal frame 12 of an implement, such as a grain drill, for forward movement over the ground (arrow direction). ) movement to place material such as seed and / or fertilizer into a furrow F formed by the device 10. A bracket 16 is connected to the universal frame 12 and includes a lower pivot 18 supporting the upper front end of the tie rod 20 . A spring support 24 is attached near the lower rear end of the tie rod 20, and a compression spring and tension link assembly 26 is biased downwardly at the rear end and when the universal frame 12 is moved from the field working position shown in FIG. When swinging to a transport position, the downward movement of the pull rod 20 about the pivot 18 is limited.

[0037] A disc 30 is supported for rotation about an axis 32 by a hub 33 and a support 34 at the lower rear end of the tie rod 20 . Axis 32 is sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com