High strength copper coated aluminum wire

A technology of copper-clad aluminum wire and copper layer, applied in the field of copper-clad aluminum wire, can solve the problems of high production cost, low tensile strength and high tensile strength, and achieve the effect of reducing product cost and solving easy fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

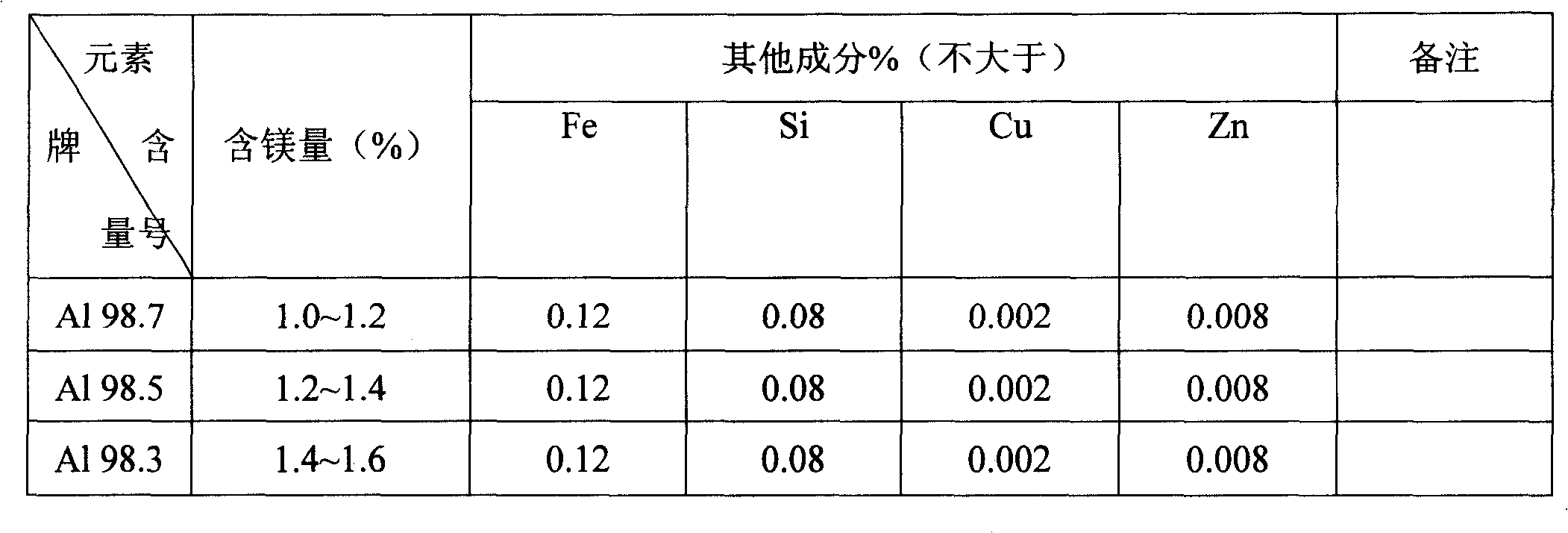

[0008] Example 1: This copper-clad aluminum wire is concentrically coated with a copper layer on the surface of the aluminum-magnesium alloy core, and the copper layer and the aluminum-magnesium alloy core are metallurgically bonded, wherein the magnesium content in the aluminum-magnesium alloy core is 1.0% to 1.2%, The content of Fe is less than 0.12%, the content of Si is less than 0.08%, the content of Cu is less than 0.002%, the content of Zn is less than 0.008%, and the rest is the aluminum content. The above is the weight ratio; the copper layer accounts for the core of the aluminum-magnesium alloy. 10-15% by volume.

Embodiment 2

[0009] Example 2: This copper-clad aluminum wire is concentrically coated with a copper layer on the surface of the aluminum-magnesium alloy core, and the copper layer and the aluminum-magnesium alloy core are metallurgically bonded, wherein the magnesium content in the aluminum-magnesium alloy core is 1.2% to 1.4%, The content of Fe is less than 0.12%, the content of Si is less than 0.08%, the content of Cu is less than 0.002%, the content of Zn is less than 0.008%, and the rest is the content of aluminum.

Embodiment 3

[0010] Example 3: This copper-clad aluminum wire is concentrically coated with a copper layer on the surface of the aluminum-magnesium alloy core, and the copper layer and the aluminum-magnesium alloy core are metallurgically bonded, wherein the magnesium content in the aluminum-magnesium alloy core is 1.4% to 1.6%, The content of Fe is less than 0.12%, the content of Si is less than 0.08%, the content of Cu is less than 0.002%, the content of Zn is less than 0.008%, and the rest is the content of aluminum.

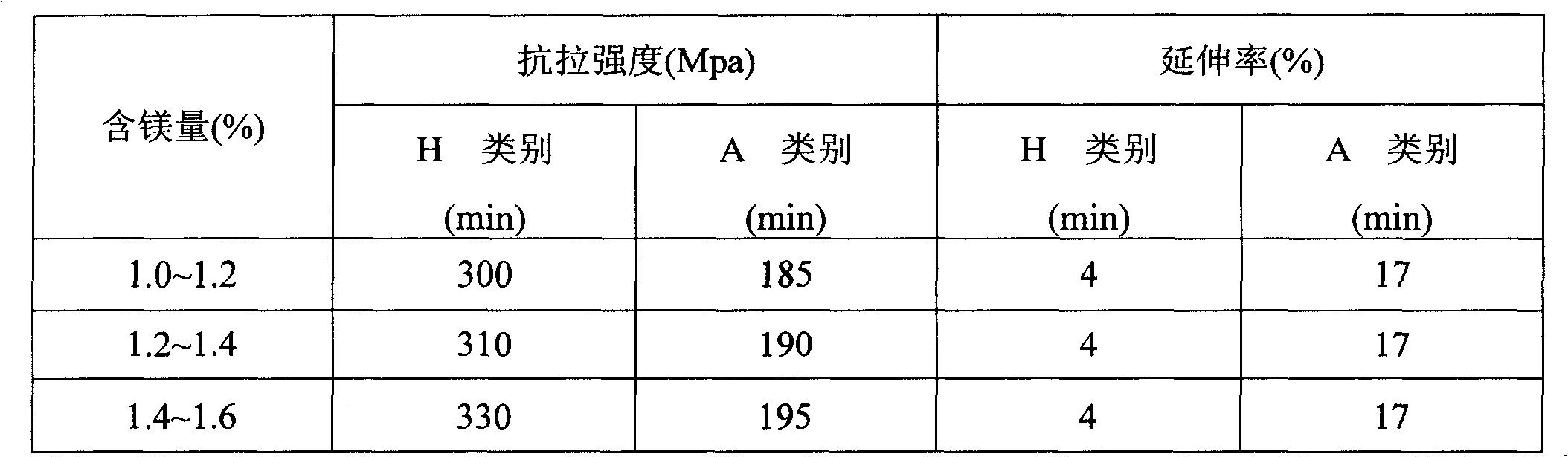

[0011] The formula of the aluminum-magnesium alloy rod of the present invention and the indicators of the produced high-strength copper-clad aluminum wire: (see the following tables).

[0012] Mechanical properties table of aluminum rod (Table 1)

[0013] grade

Magnesium content (%)

Tensile Strength(Mpa)

Elongation (%)

Resistivity

Remark(%)

A198.7

1.0~1.2

155

15

≤0.04544

Contains 1.2

A198.5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com