A kind of preparation method of continuous basalt fiber

A technology of basalt fiber and basalt, which is applied in the field of continuous basalt fiber preparation, can solve the problems of basalt fiber toughness reduction, large internal stress, waste of energy, etc., reduce heating and melting time, improve toughness and tensile strength, and reduce energy consumption The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

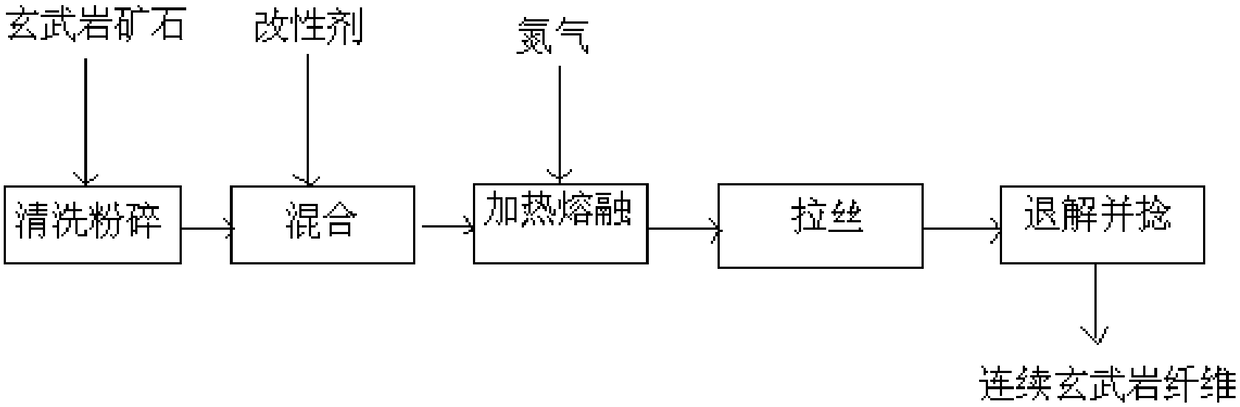

Method used

Image

Examples

Embodiment 1

[0032] 1) Immerse 100kg of basalt ore in a pool, wash it, remove impurities that may be attached to the surface, then take it out to dry, and crush the dried basalt ore with a pulverizer to a fineness of 2mm to obtain basalt ore powder;

[0033] 2) Ball mill and mix the basalt ore powder obtained in step 1) with 0.001 kg of graphene for 1 hour, and discharge after mixing evenly to obtain the mixed powder;

[0034] 3) Add the mixed powder obtained in step 2) into the kiln, and feed nitrogen into the kiln, raise the temperature to 1300°C, and stir at the same time, so that the basalt powder is completely melted, and the modifier is uniformly dispersed and suspended in the basalt A spinning melt is formed in the melt;

[0035] 4) Drawing the spinning melt obtained in step 3) with a platinum-rhodium alloy drawing bushing with 200 holes and a temperature of 1200°C at a speed of 1500m / min to obtain basalt fiber precursors;

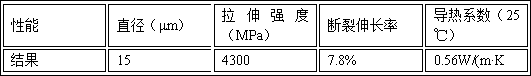

[0036] 5) The raw silk obtained in step 4) is unwound and...

Embodiment 2

[0040]1) Immerse 100kg of basalt ore in a pool, wash it, remove impurities that may be attached to the surface, then take it out to dry, and crush the dried basalt ore with a pulverizer to a fineness of 1mm to obtain basalt ore powder;

[0041] 2) Mix the basalt ore powder obtained in step 1) with 0.1 kg of graphene oxide by ball milling for 2 hours, and discharge after mixing evenly to obtain the mixed powder;

[0042] 3) Add the mixed powder obtained in step 2) into the kiln, heat up to 1500°C, and stir at the same time to completely melt the basalt powder, and the modifier is evenly dispersed and suspended in the basalt melt to form a spinning melt;

[0043] 4) Drawing the spinning melt obtained in step 3) with a platinum-rhodium alloy drawing bushing with 800 holes and a temperature of 1300°C at a speed of 3000m / min to obtain basalt fiber precursors;

[0044] 5) The raw silk obtained in step 4) is unwound and twisted to form a complete continuous basalt fiber.

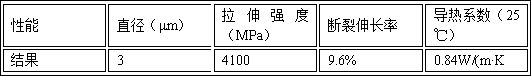

[0045] Af...

Embodiment 3

[0048] 1) Immerse 100kg of basalt ore in a water pool, rinse to remove impurities that may be attached to the surface, then take it out to dry, and crush the dried basalt ore with a pulverizer to a fineness of 0.5mm to obtain basalt ore powder ;

[0049] 2) Ball mill and mix the basalt ore powder obtained in step 1) with 0.01 kg of graphene for 1 hour, and discharge after mixing evenly to obtain the mixed powder;

[0050] 3) Add the mixed powder obtained in step 2) into the kiln, and feed nitrogen into the kiln, raise the temperature to 1400°C, and stir at the same time, so that the basalt powder is completely melted, and the modifier is evenly dispersed and suspended in the basalt A spinning melt is formed in the melt;

[0051] 4) Drawing the spinning melt obtained in step 3) with a platinum-rhodium alloy drawing bushing with 400 holes and a temperature of 1250°C at a speed of 2500m / min to obtain basalt fiber precursors;

[0052] 5) The raw silk obtained in step 4) is unwou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com