Welded area structure of printed circuit board for washing machine controller

A technology for printed circuit boards and soldering areas, which is applied in the field of soldering area structures, can solve problems such as weak bonding and semiconductor element 200 falling off, and achieve the effects of improving bonding force, improving installation reliability, improving productivity and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

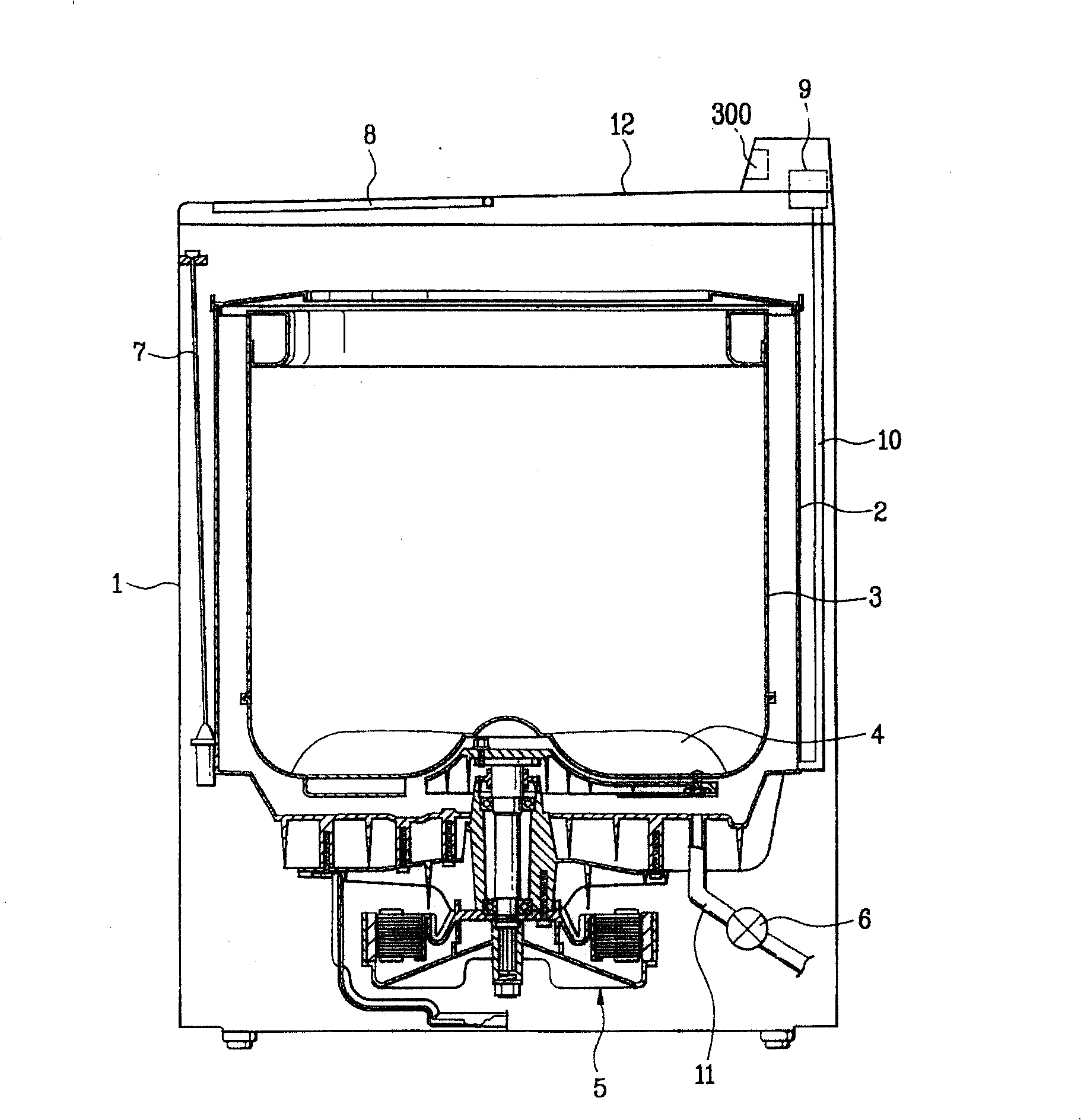

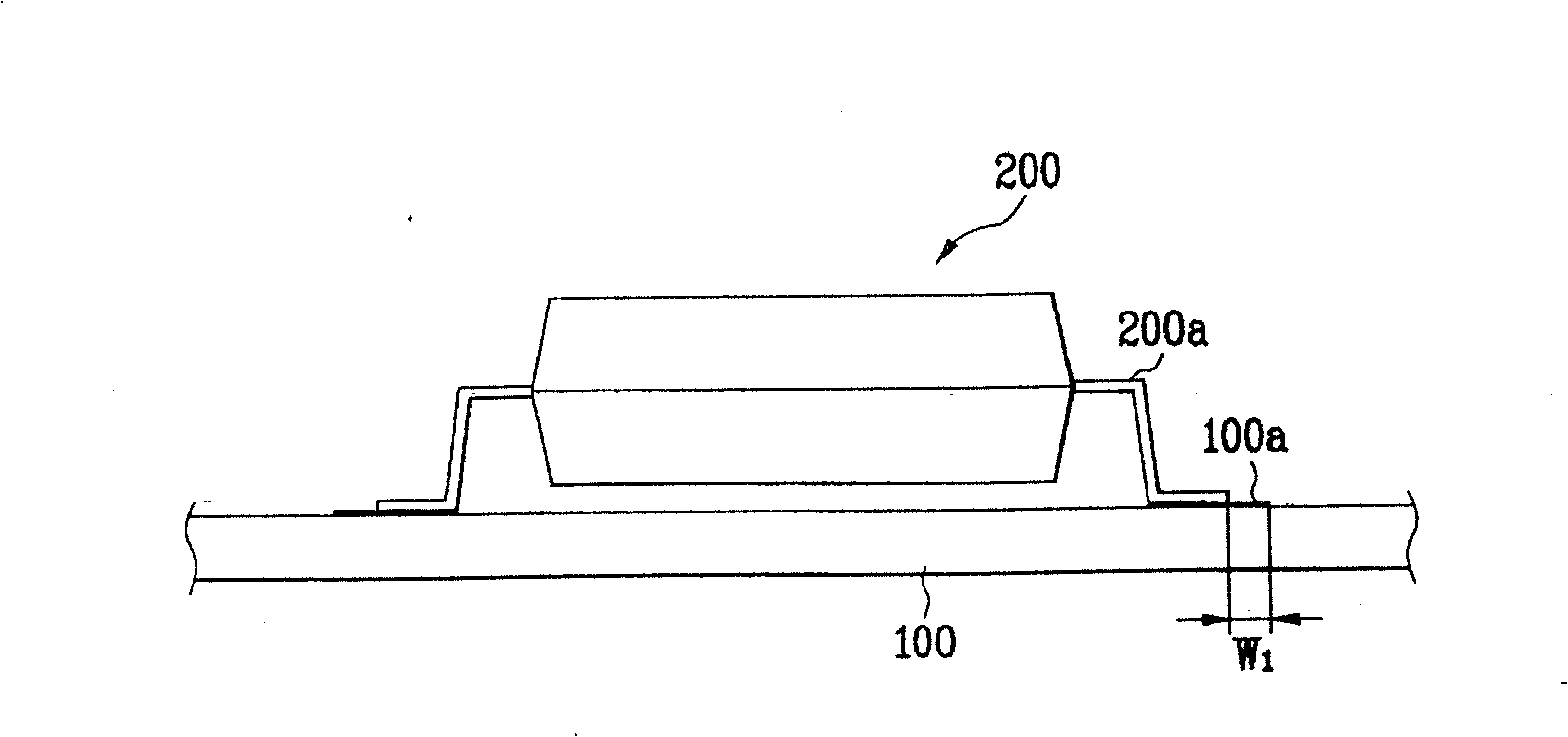

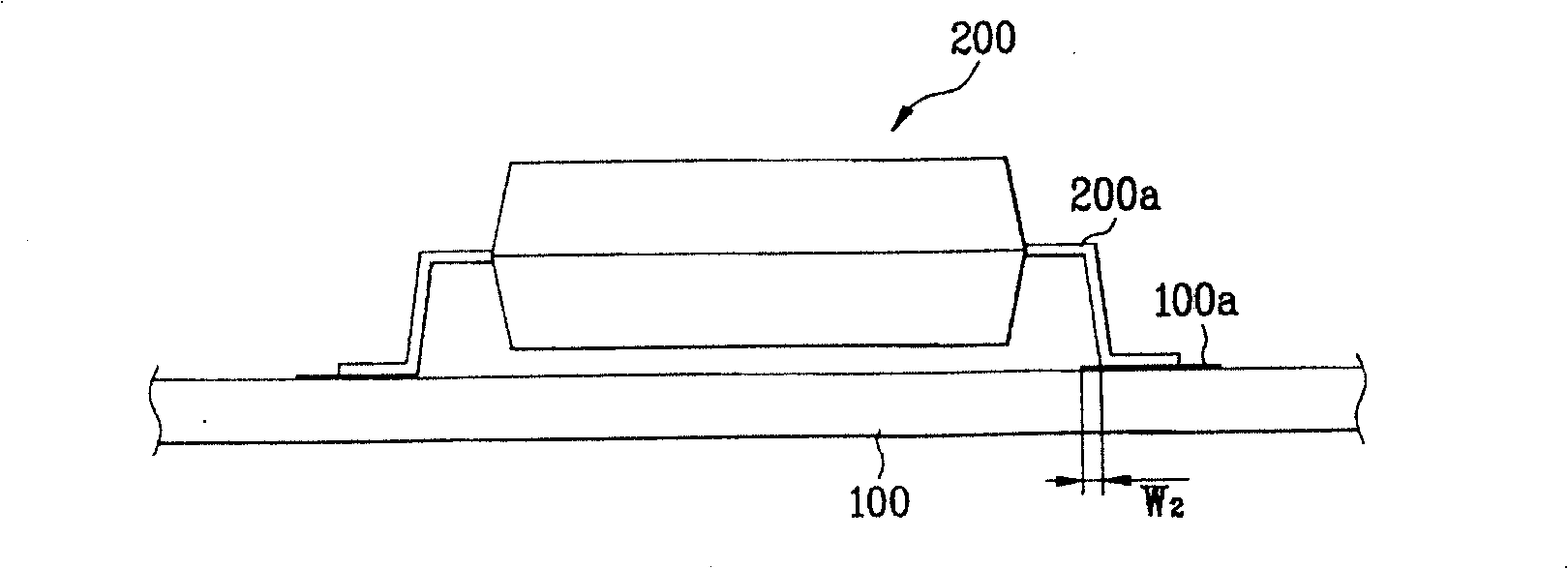

[0034] Refer to the attached image 3 , the embodiment of the welding structure of the printed circuit board of the washing machine controller of the present invention will be described in detail.

[0035] image 3 A longitudinal sectional view showing the main part of the present invention.

[0036] like image 3 As shown, the printed circuit board of the washing machine controller includes the following structures: a printed circuit board body 100 , a semiconductor element 200 and a urethane coating layer. A circuit pattern (pattern) is formed on the above-mentioned printed circuit board body 100; a plurality of the above-mentioned semiconductor elements 200 are installed on the above-mentioned printed circuit board body 100; And semiconductor element 200 invades; To the printed circuit board of above-mentioned controller, the printed circuit board structure of the controller that the present invention provides has following feature: the bottom surface (bottom surface) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com