Welding technology for broken and waste core rod

A welding process and mandrel technology, which is applied in the field of reuse of waste mandrels, and can solve problems such as unusable waste mandrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The welding process of the waste mandrel of the present invention will be described in conjunction with the accompanying drawings and embodiments.

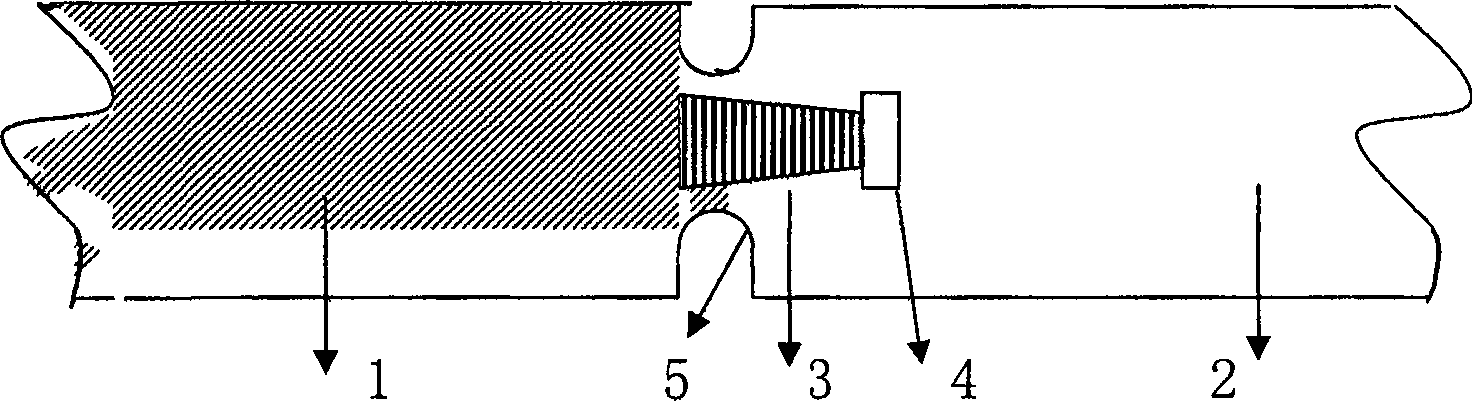

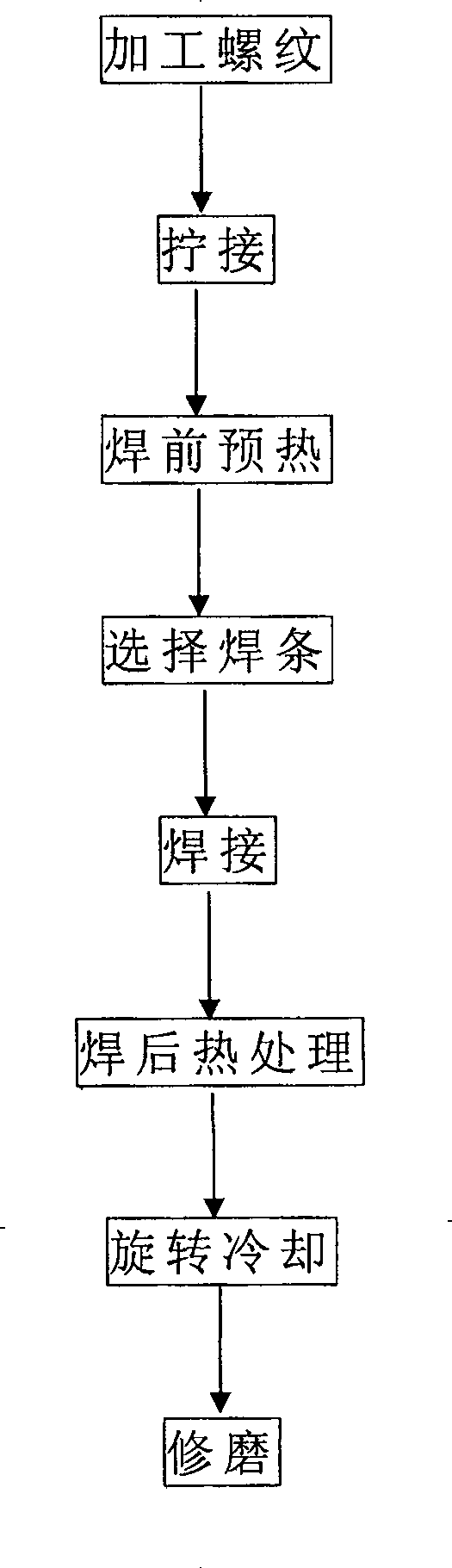

[0032] The structure of the broken mandrel after welding is as follows figure 1 As shown, in order to ensure that there will be no broken mandrel accidents in production, reduce welding workload, reduce repair costs, and ensure the straightness of the mandrel, firstly, the rear section of the broken mandrel 1 is machined into a threaded connection with a ladder buckle. Column 3, on the front broken mandrel 2, a threaded hole matching the threaded connection column 3 with a partial ladder buckle is processed, and an undercut 4 is left, between the rear broken mandrel 1 and the front broken mandrel 2 A U-shaped welding groove 5 is processed at the butt joint. The advantage of the U-shaped groove is that it can save welding materials and reduce the labor intensity of welders.

[0033] Then use the mandrel screwing machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com