A backlight source module

A backlight and module technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as unfavorable heat conduction, optical diaphragm warping, large axial temperature difference of CCFL, etc., to increase heat conduction space and improve structure Compact, eliminates the effect of heat concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

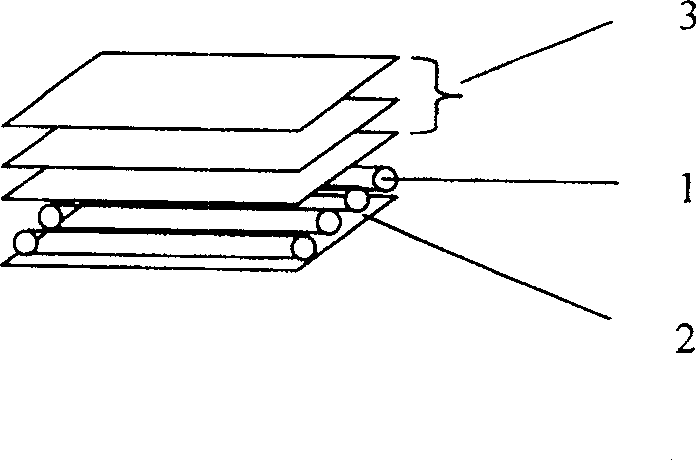

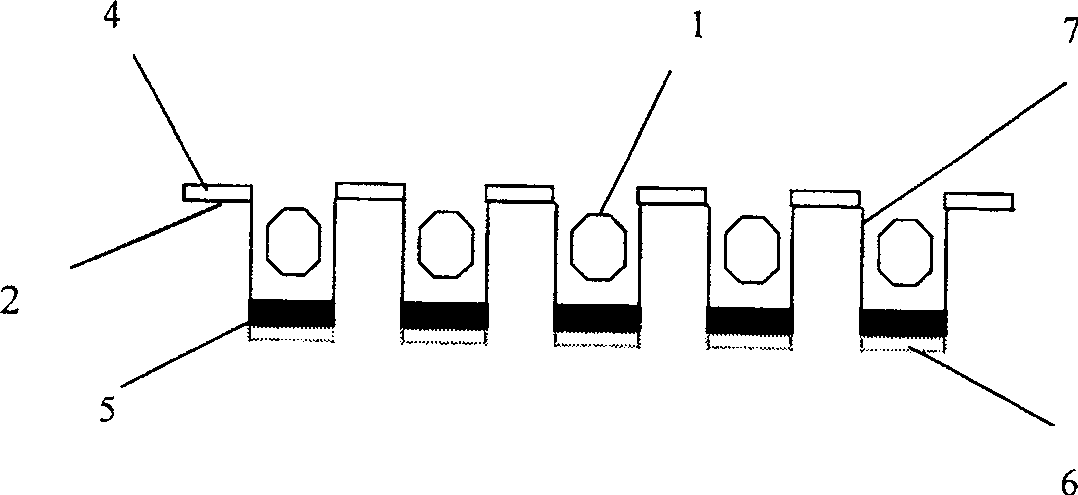

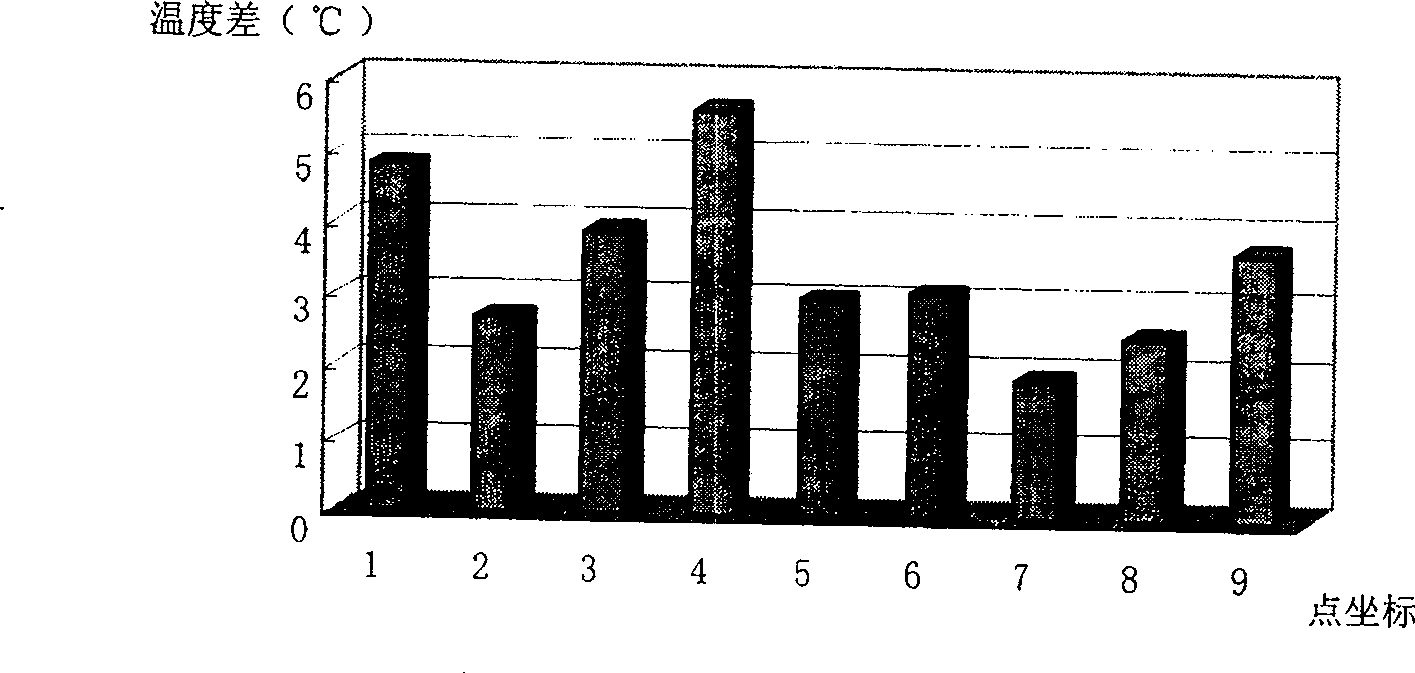

[0018] The structure of the backlight module of the present invention includes optical films such as a metal base plate, a bottom reflection film, a CCFL lamp group, a diffusion film, a prism sheet, and a protective film, and a rubber frame, and these parts are the same as those of the backlight module in the prior art. , the present invention is different from the prior art in that: as figure 2 As shown, a groove 7 is punched out on the metal base plate 2 at the position corresponding to CCFL 1. Generally, 8 U-shaped lamp tubes can be placed. The depth of the groove is about 3-5 mm larger than the radius r of CCFL. Coated on the inner surface of the metal base plate 2 (including the groove 7); CCFL 1 is respectively placed in the groove 7 of the metal base plate 2, and the plane where the axis is located is located below the reference plane where the bottom reflection film 4 is located or the inner surface of the metal base plate 2; The bottom of the groove 7 below the CCFL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com