Method for improving light intensity detector measuring accuracy

A technology of light intensity detector and measurement accuracy, which is used in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of complex calibration test, rough adjustment of workpiece table, etc. The effect of improving the accuracy of position measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

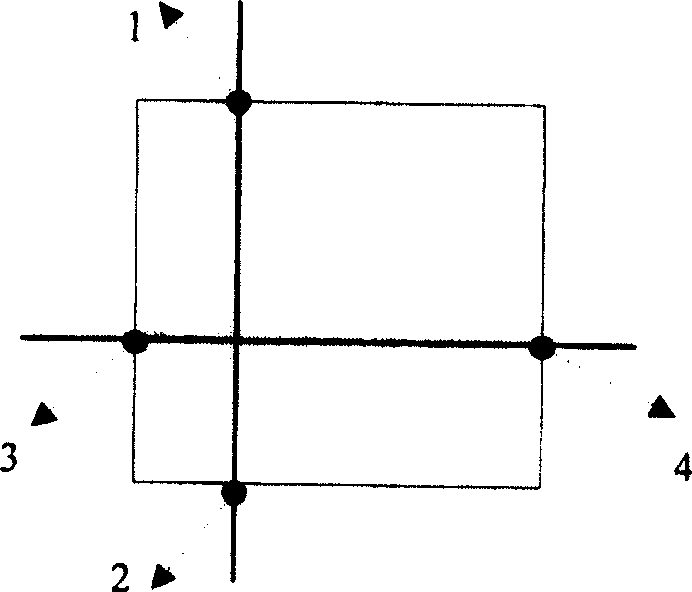

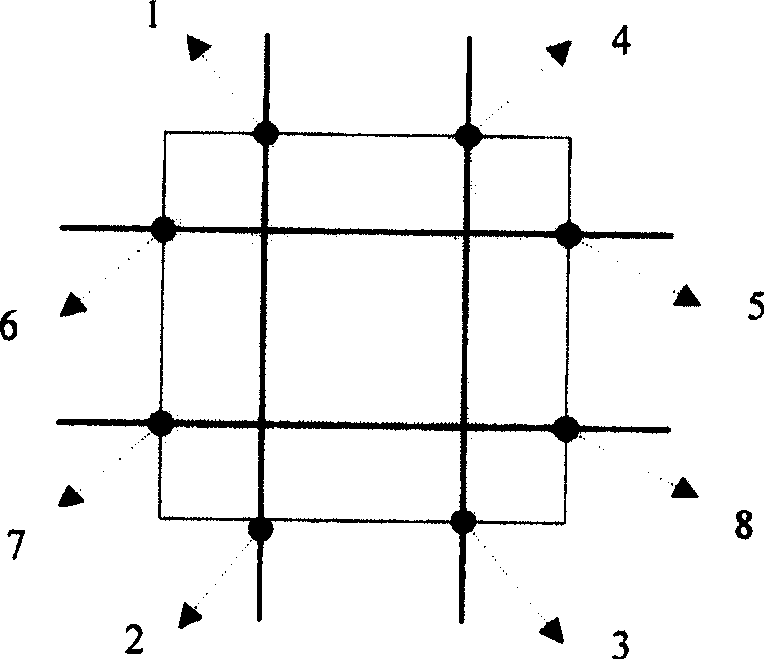

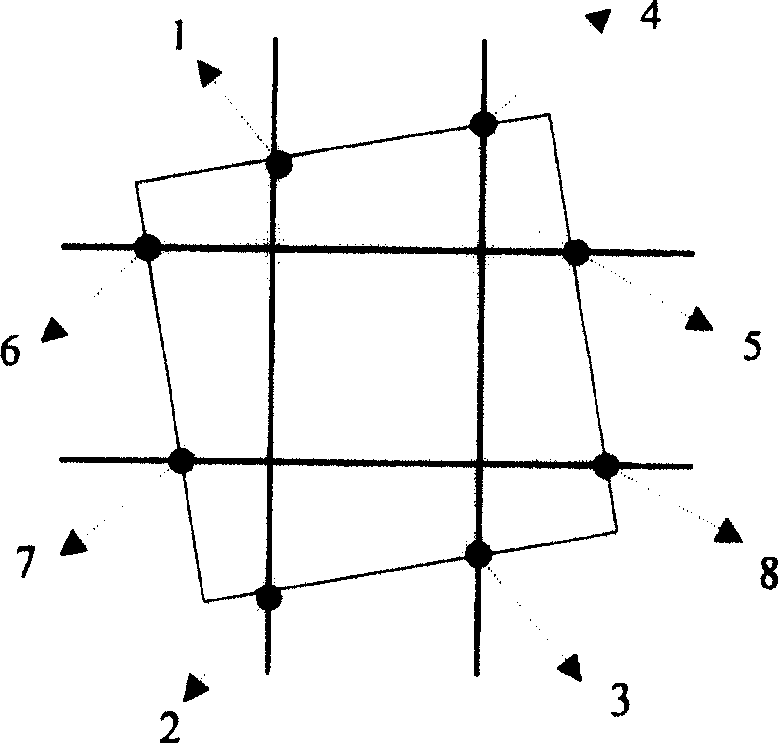

[0040] The main idea of a method for improving the measurement accuracy of the light intensity detector in the present invention is to omit the pre-alignment of the test precondition mask and increase the number of sampling points for scanning 50% light intensity.

[0041] figure 2 In the test schematic diagram of the test, the light intensity detector adopts the distribution layout of eight points for the scanning sampling of the projected light area of the light hole on the mask on the workpiece table, and the pre-alignment of the mask, which is the precondition of the test, is omitted. Set at least 8 light intensity sampling points for scanning in the two mutually perpendicular directions of X and Y, and the value range of light intensity is set between >0% and <100% of the reference light intensity.

[0042] The specific operation method is:

[0043] (1) Scan in the two vertical directions of X and Y respectively, and find at least 8 sampling points with 50% light in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com