Yarn Sensor

A sensor and yarn technology, applied in the field of yarn sensors, can solve the problems of drift of electrical components, distortion of measurement results, temperature rise of shell, etc., and achieve the effect of eliminating temperature rise, improving quality and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The application and arrangement of yarn sensors on textile machines, such as spinning machines or winding machines, are already known, for example, from the above-mentioned documents and will therefore not be described in detail here.

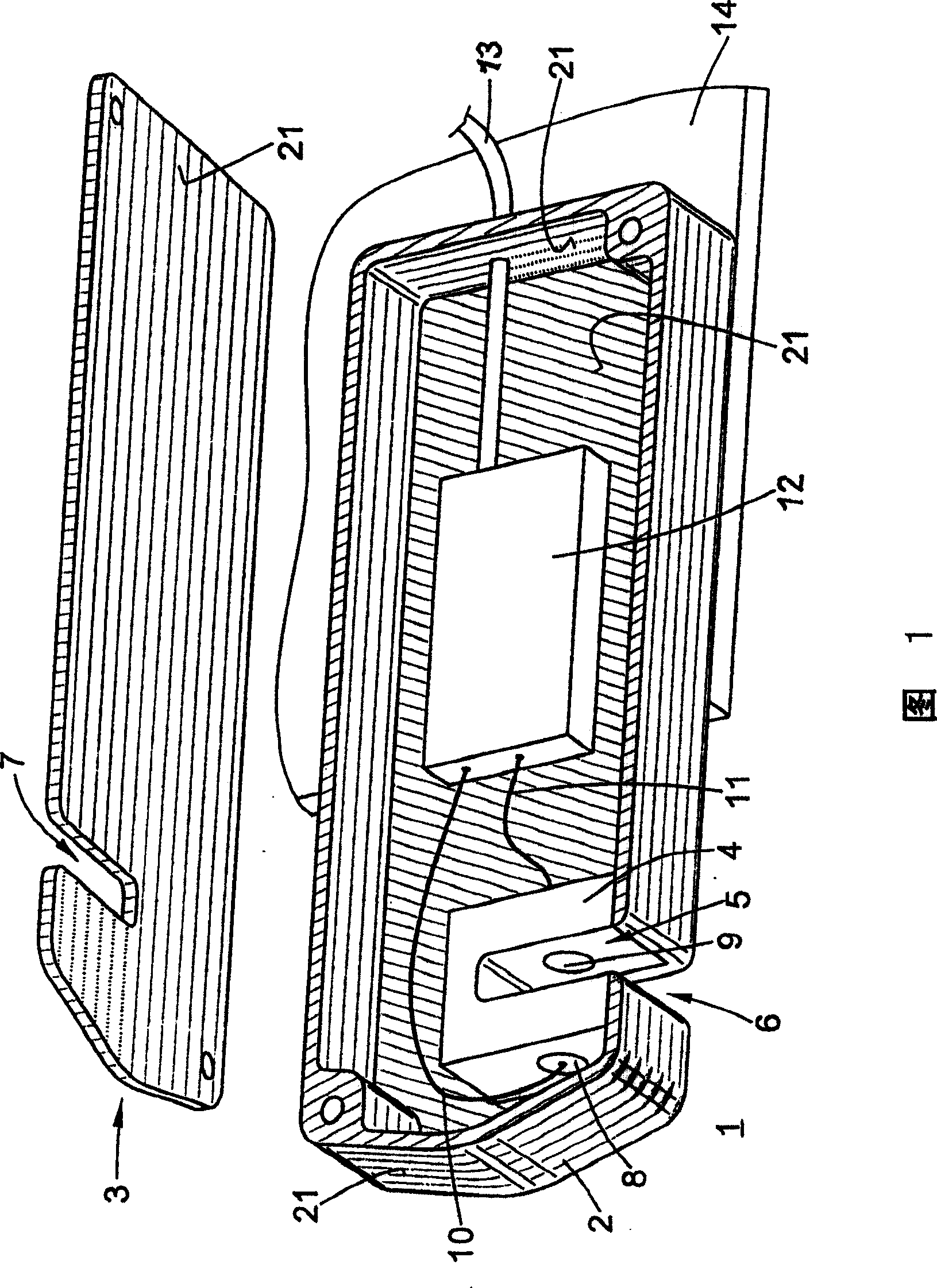

[0026] The thread sensor 1 shown in FIG. 1 has a housing comprising a box-shaped base body 2 with a removable cover 3 . The measuring device 4 is arranged in the base body 2 with a measuring gap 5 through which the yarn passes in the longitudinal direction during the measuring process. In the embodiment of FIG. 1 , the surface of the measuring gap 5 has no metal coating. The base body 2 and the cover 3 each have a recess 6 , 7 which is positioned in correspondence with the measuring gap 5 .

[0027] Measuring device 4 operates with a light sensor 9 of a light source 8 , which are each connected via lines 10 and 11 to a processor 12 . The processor 12 is attached to the bottom of the base body 2 and is designed as a so-called ASIC (Appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com