A combined cleaning sift

A sieve box and flat sieve technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of reducing the process effect of the equipment, affecting the processing capacity, uneven feeding, etc., to avoid dust overflow and ensure clean production. , good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

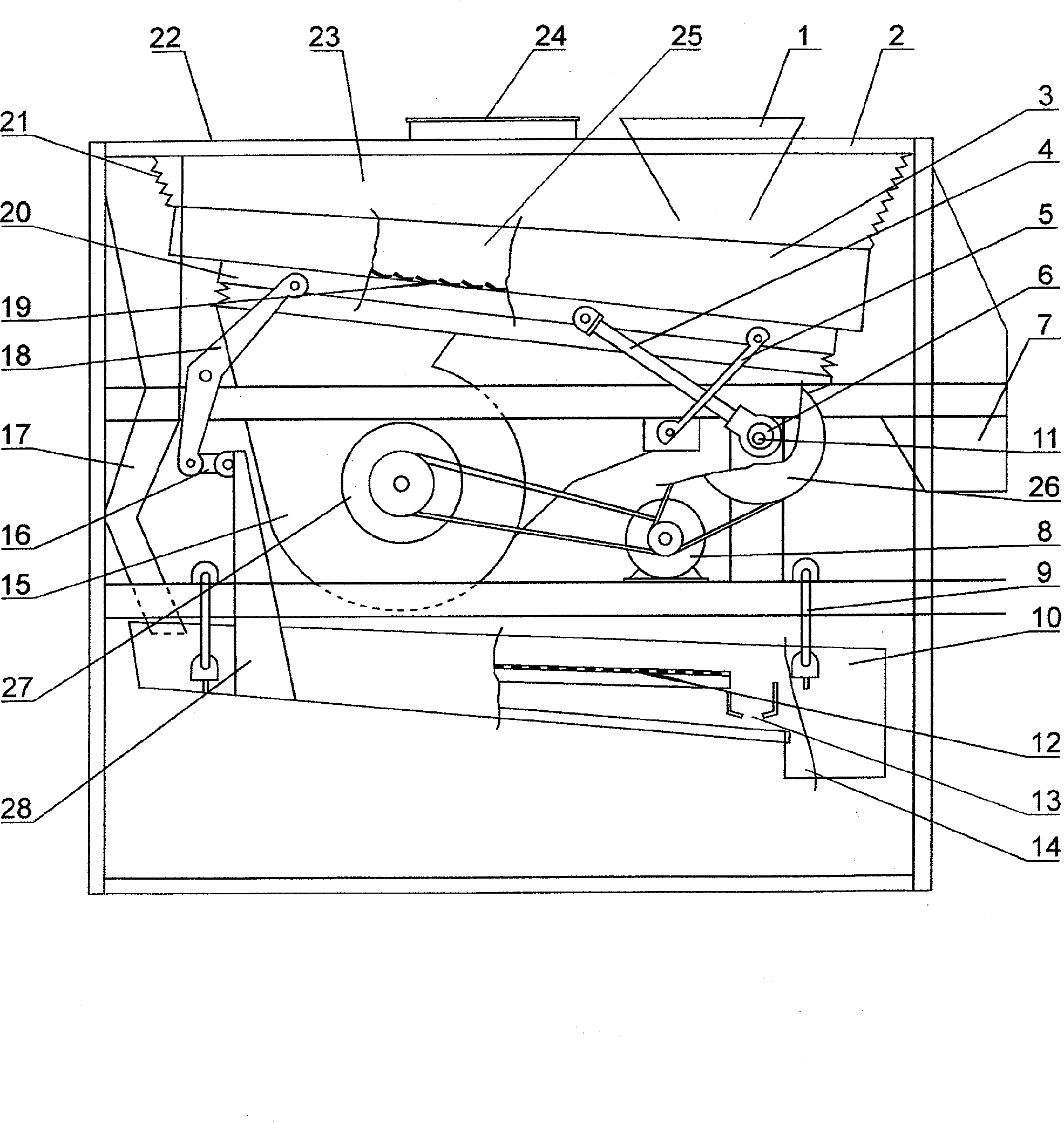

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0022] Present embodiment is provided with frame 2, and frame 2 includes upper sorting box 23, lower screen box 10, blower fan 15 and motor 8, upper and lower setting of upper sorting box 23 and lower screen box 10, and two boxes The flow guide 17 communicates between them. A gravity sorting platform 3 is arranged in the upper sorting box 23 , and a flat screen 12 is arranged in the lower screening box 10 .

[0023] The blower fan 15 is arranged on the lower side of the upper sorting box 23, and the lower side of the gravity sorting table 3 communicates with the air outlet of the blower fan 15. Between the casing of fan 15 and the gravity sorting table 3 and between the gravity sorting table 3 and the upper cover plate of the frame 2, needle-punched breathable cloth 21 is used as soft connection, so that the material is in the upper sorting box 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com