Small radio communication module and manufacturing method thereof

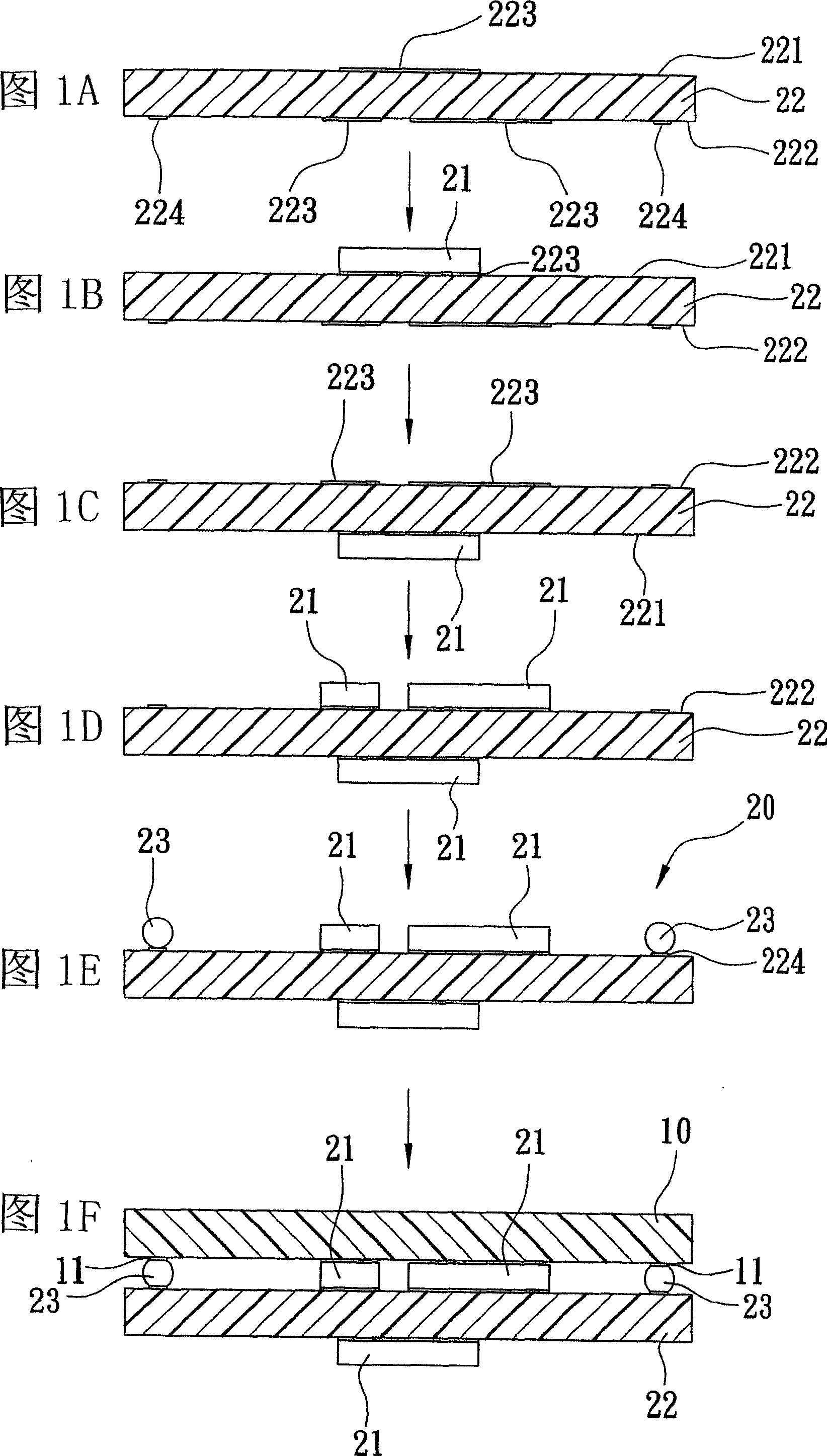

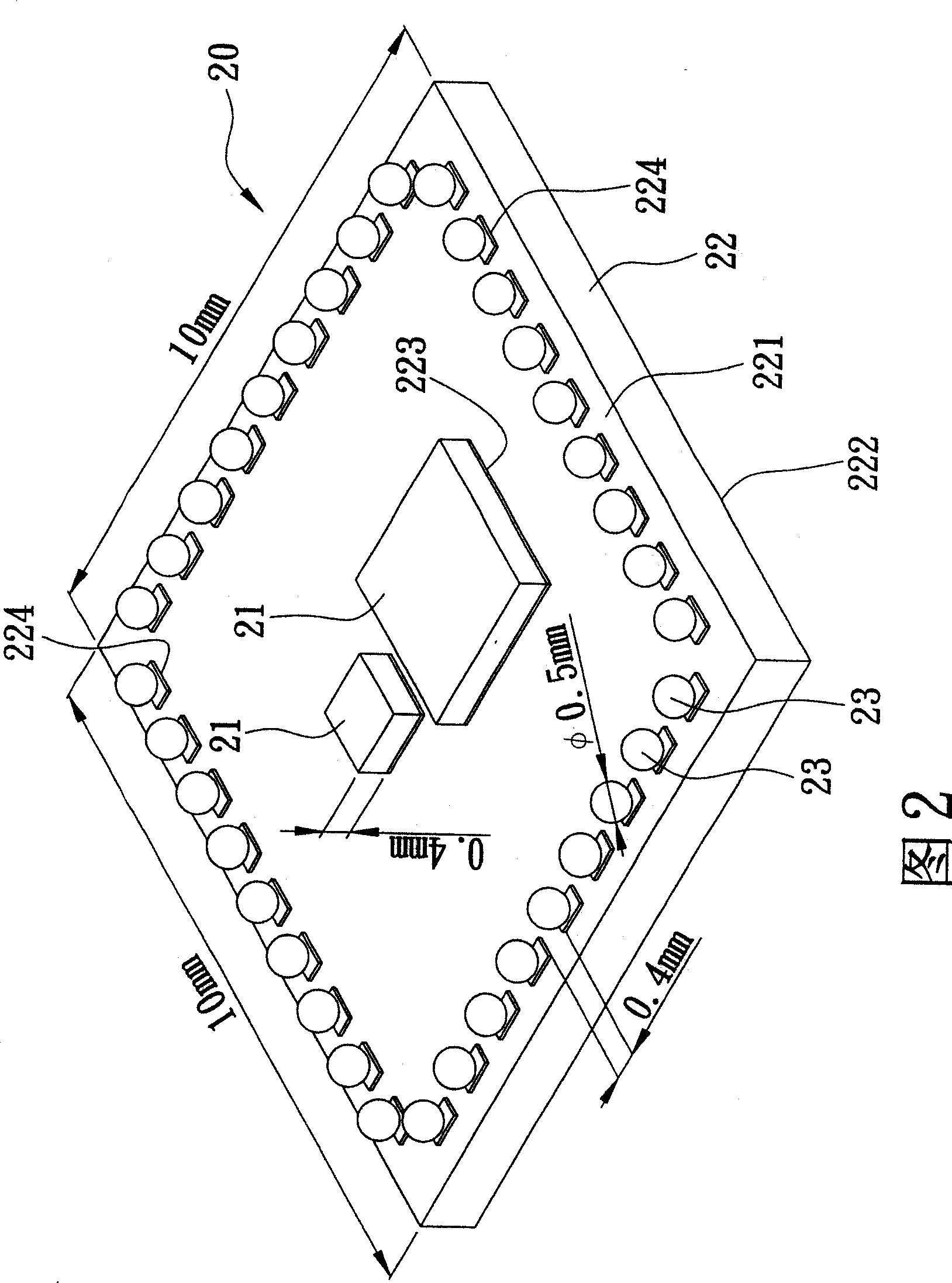

A wireless communication module and wireless communication technology, applied in the field of communication modules, can solve the problems of short circuit, enlargement, and difficulty in controlling the overall height of the solder ball 23, and achieve the effect of accurate overall height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

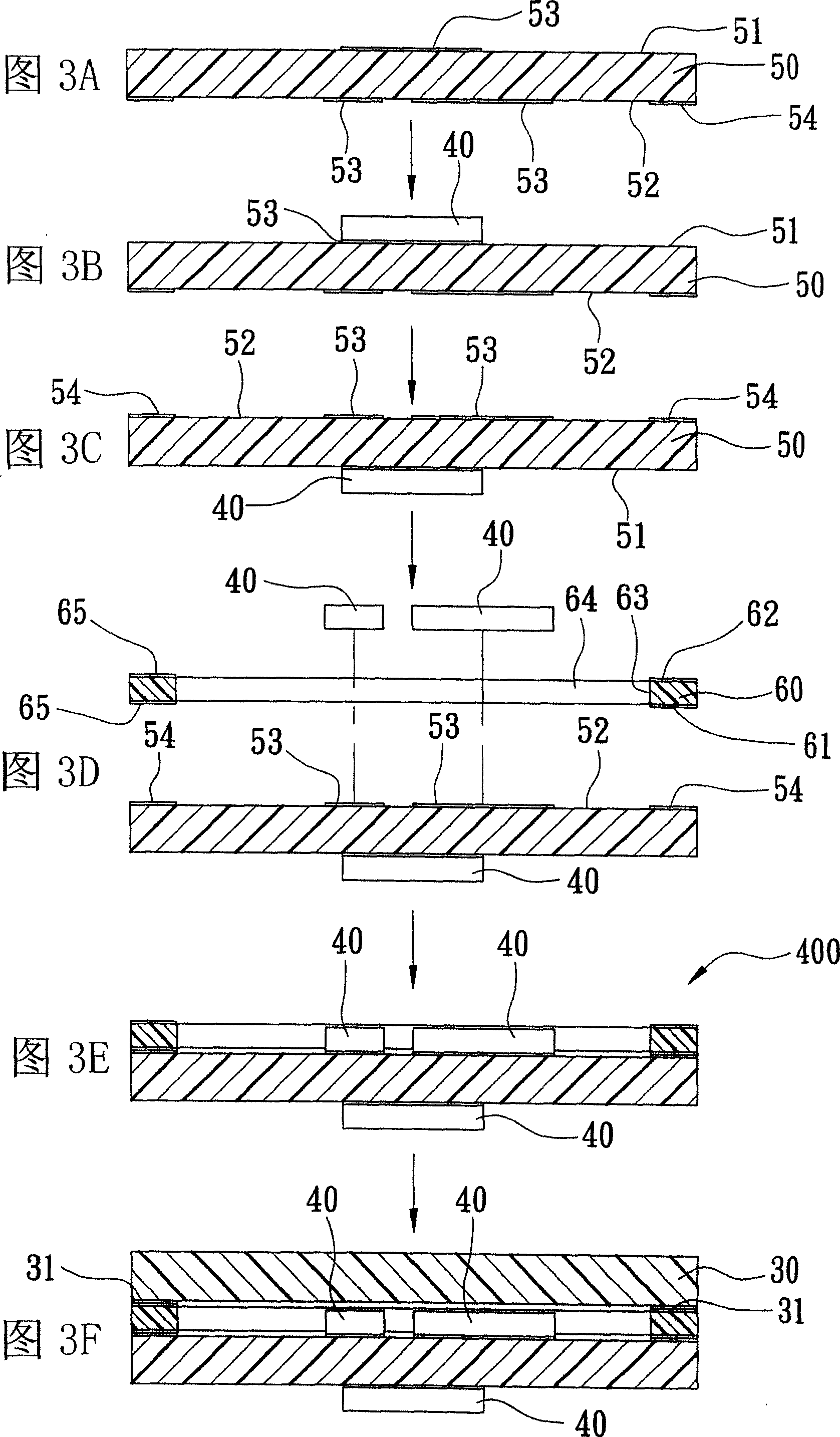

[0034] As shown in Figures 3A-3F and 4, the first preferred embodiment of the miniaturized wireless communication module of the present invention is used to be arranged in a device with a wireless communication function, and the device includes a host with a plurality of welding pads 31 board 30 , the miniaturized wireless communication module 400 includes three chips 40 , a module substrate 50 , and a carrier substrate 60 .

[0035] One of the chips 40 is a chip for a communication circuit.

[0036] The module substrate 50 includes a top surface 51, a bottom surface 52, a plurality of first welding pads 53 arranged on the top surface 51 and the bottom surface 52, and a plurality of second welding pads 54 arranged on the bottom surface 52. The pad 53 is located in the middle, the second pad 54 is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com