Straight-line organic electroluminescence mfg. device

A manufacturing device and luminescent technology, which is applied in the direction of electroluminescent light source, electric light source, lighting device, etc., can solve the problems of long substrate production time, position deviation, poor film quality, etc., and achieve high productivity and high-speed transportation Speed, the effect of suppressing the rise in temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

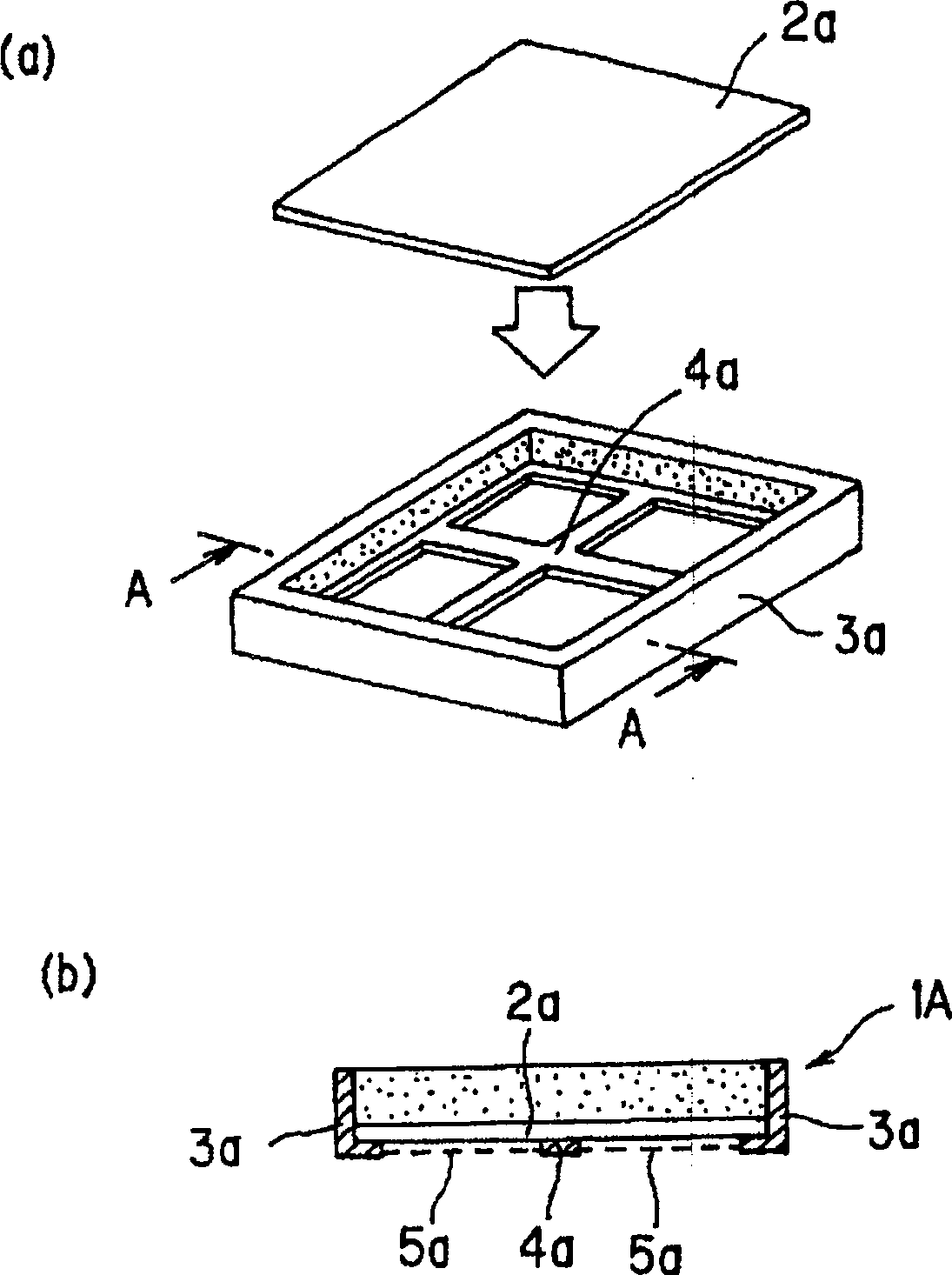

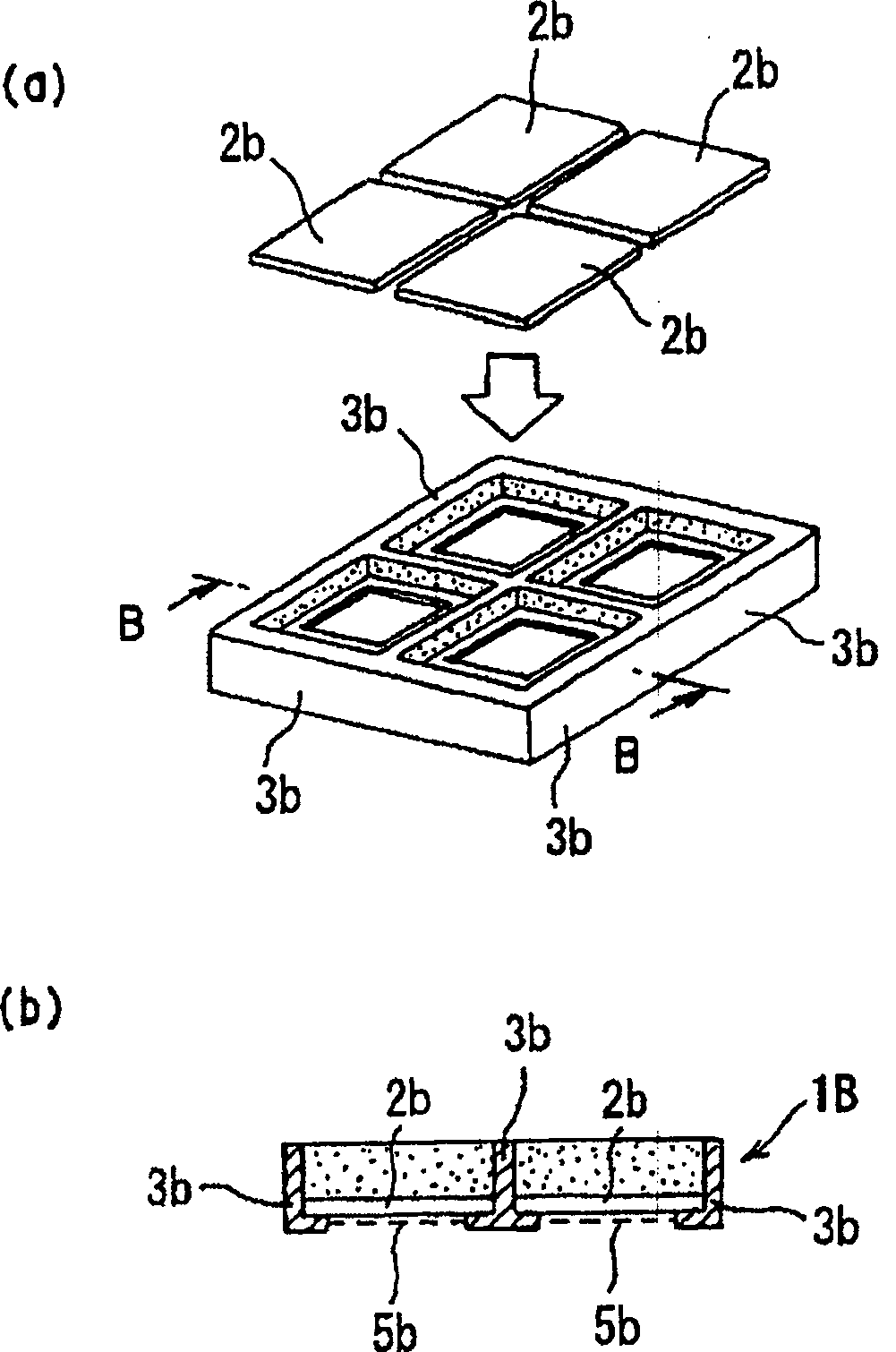

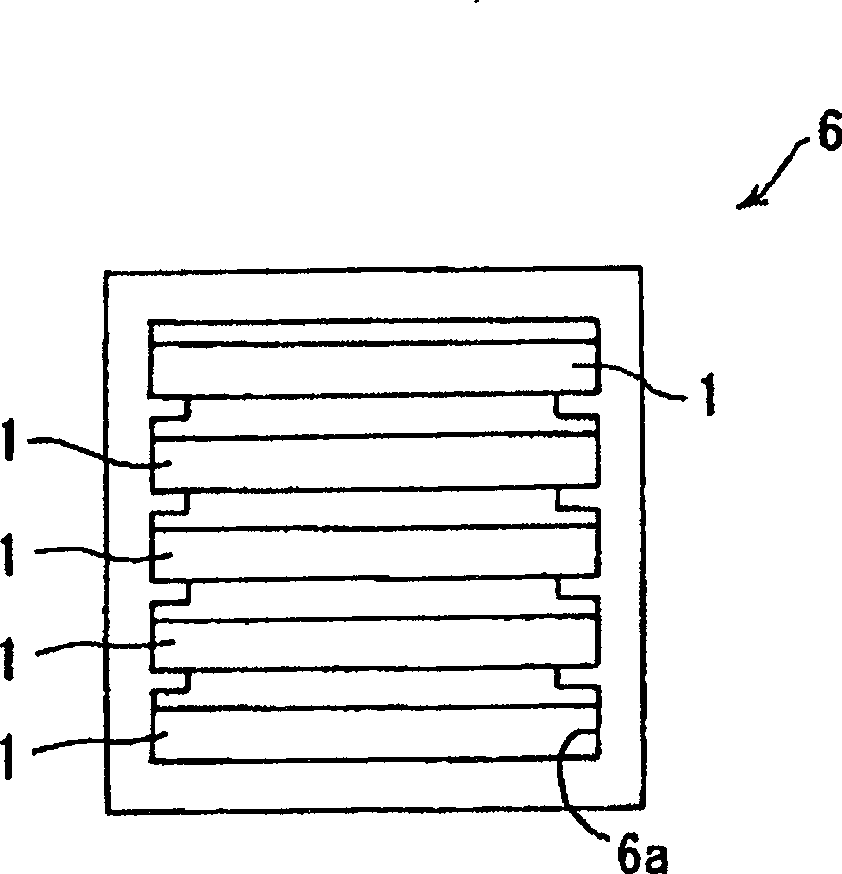

[0057] figure 1 , figure 2 An embodiment of the holder used in the in-line organic EL manufacturing apparatus of the present invention is shown.

[0058] in addition, figure 1 (a), figure 2 (a) is a perspective view of the substrate and support, figure 1 (b), figure 2 (b) represent respectively figure 1 (a) A-A line view sectional view, figure 2 (a) The sectional view taken along the line B—B.

[0059] Such as figure 1 As shown, the stand 1A (supporting device) has a frame 3a with an L-shaped cross-section supporting the peripheral portion of a rectangular substrate 2a from its lower side, and a cross-shaped central portion of the frame 3a that supports the rectangular substrate 2a from its lower side. The supporting member 4a is provided with a mask 5a for forming a film pattern to be formed in the opening portion formed by the frame 3a and the cross-shaped supporting member 4a. In addition, the support member 4a is not limited to a cross shape, For example, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com