Bionic furrow opener

A ditch opener and bionic technology, applied in the field of bionic ditch openers, can solve problems such as entanglement of grass, increased resistance, and clay in ditching parts, and achieve the effects of reducing soil resistance, reducing power consumption, and improving the quality of sowing and fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

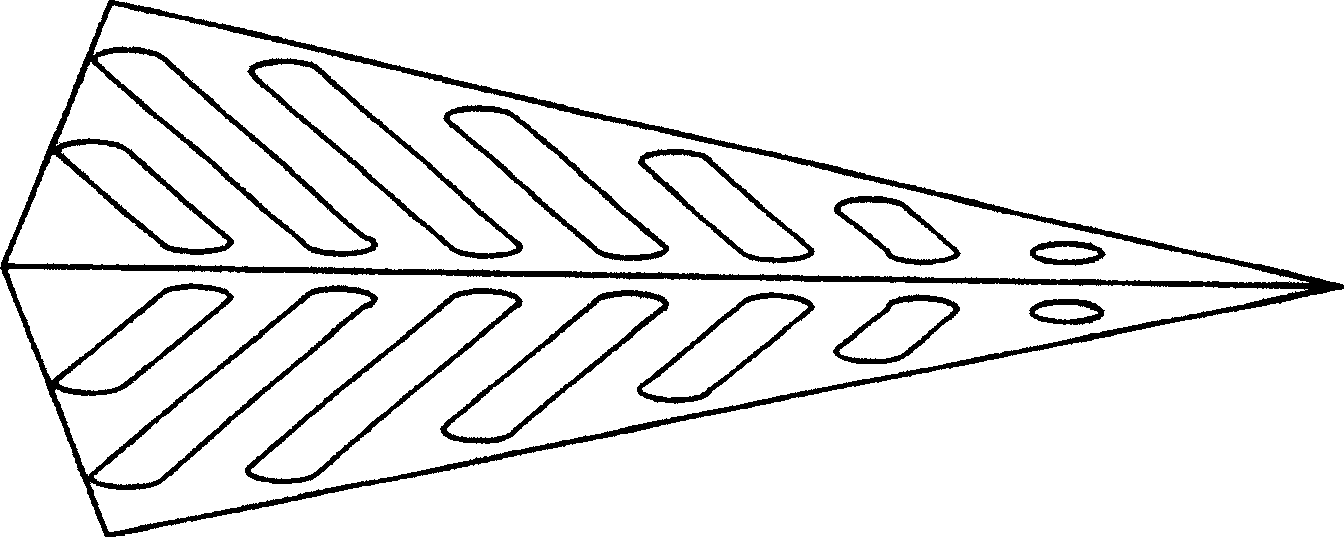

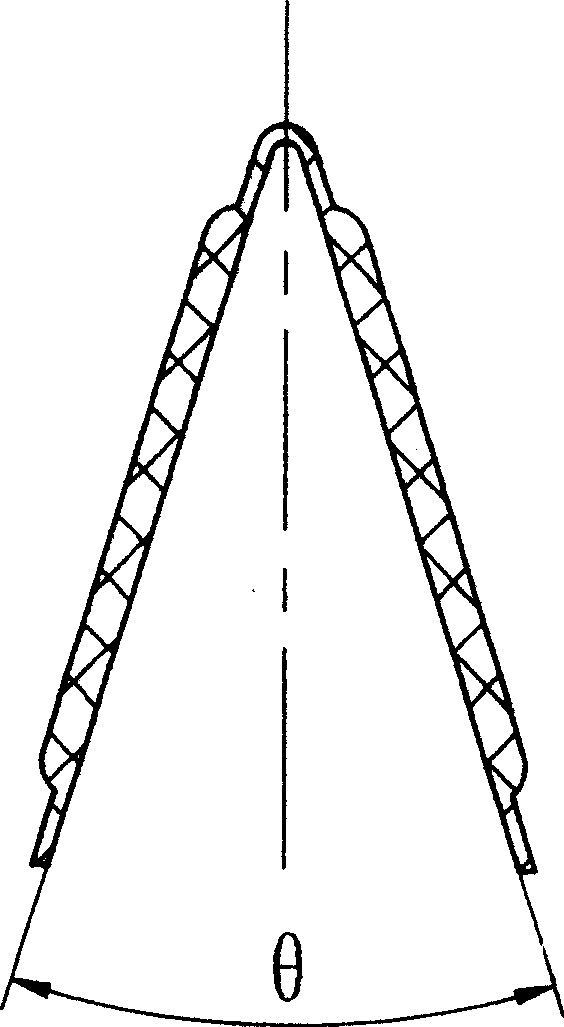

[0030] Example 1 see Figure 6 :

[0031] The vertical side length A of the opener is 108mm, the horizontal side length B is 170mm, the hypotenuse side length C is 253mm, the thickness H of the shovel body matrix is 2mm, and the material is ultra-high molecular weight polyethylene and its composite materials and other hydrophobic materials. It is integrated with the rib and bonded with the metal substrate. The height T of the geometric structure unit is 3mm, the width W is 10mm, the distance K between the edge end and the edge of the shovel body is 8mm, and the distance M between the convex ribs of the geometric structure is 20mm. The angle β between the convex rib and the soil cutting surface is 75°, and the angle θ between the two shovel blades is 25°.

example 2

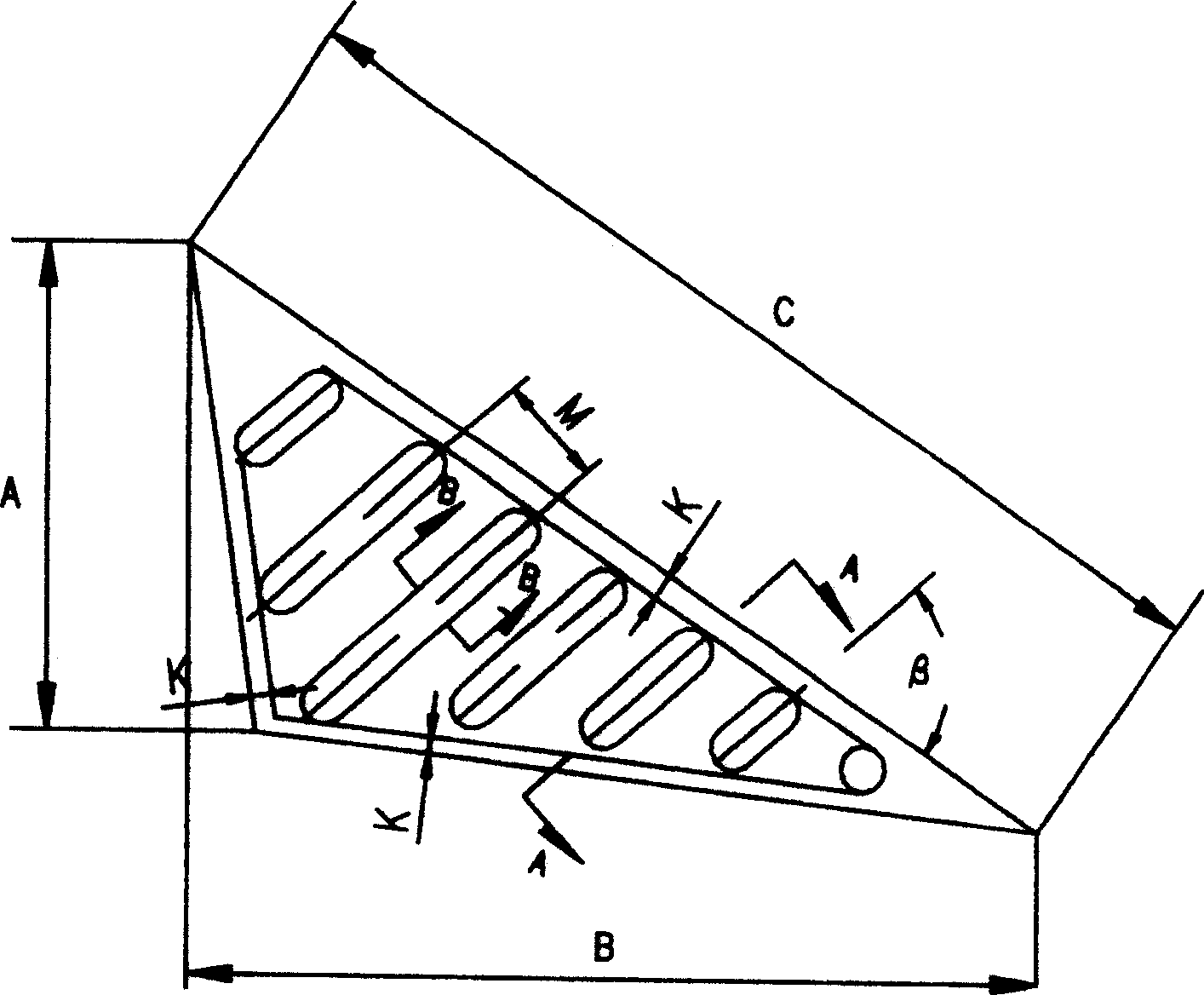

[0032] Example 2 see figure 1 :

[0033] The vertical side length A of the opener is 108mm, the horizontal side length B is 170mm, the hypotenuse side length C is 253mm, the thickness H of the shovel body matrix is 2mm, and the material is ultra-high molecular weight polyethylene and its composite materials and other hydrophobic materials. It is integrated with the convex rib and bonded with the metal substrate. The height T of the geometric structure unit is 4mm, the width W is 7mm, the distance K between the edge end and the edge of the shovel body is 10mm, and the distance M between the convex ribs of the geometric structure is 10mm. The angle β between the convex rib and the soil cutting surface is 90°, and the angle θ between the two shovel blades is 25°.

example 3

[0034] Example 3 see Figure 7 :

[0035] The vertical side length A of the opener is 108mm, the horizontal side length B is 170mm, the hypotenuse side length C is 253mm, the thickness H of the shovel body matrix is 2mm, and the material is ultra-high molecular weight polyethylene and its composite materials and other hydrophobic materials. It is integrated with the convex rib and bonded with the metal substrate. The height T of the geometric structure unit is 5mm, the width W is 8mm, the distance K between the edge end and the edge of the shovel body is 12mm, and the geometric structure convex rib spacing M is 18mm. The angle β between the convex rib and the soil cutting surface is 105°, and the angle θ between the two shovel blades is 25°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com