Construction method for matching backwash in water purification building filter layer

A technology for backwashing and water purification buildings, which is applied in construction, water supply installations, drinking water installations, etc., can solve problems such as clogging, stabilize water production, improve water supply quality, and reduce engineering investment and water production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

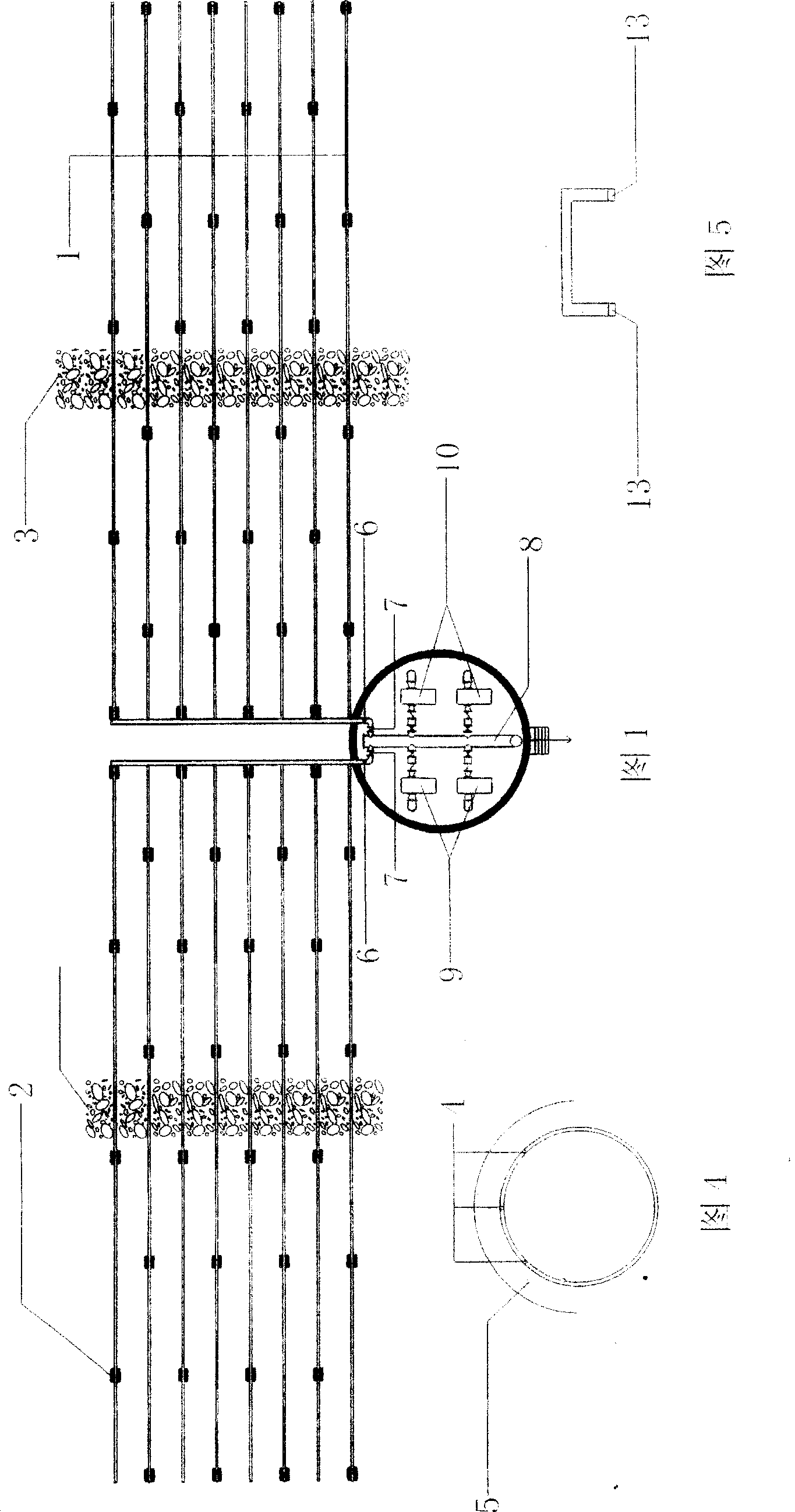

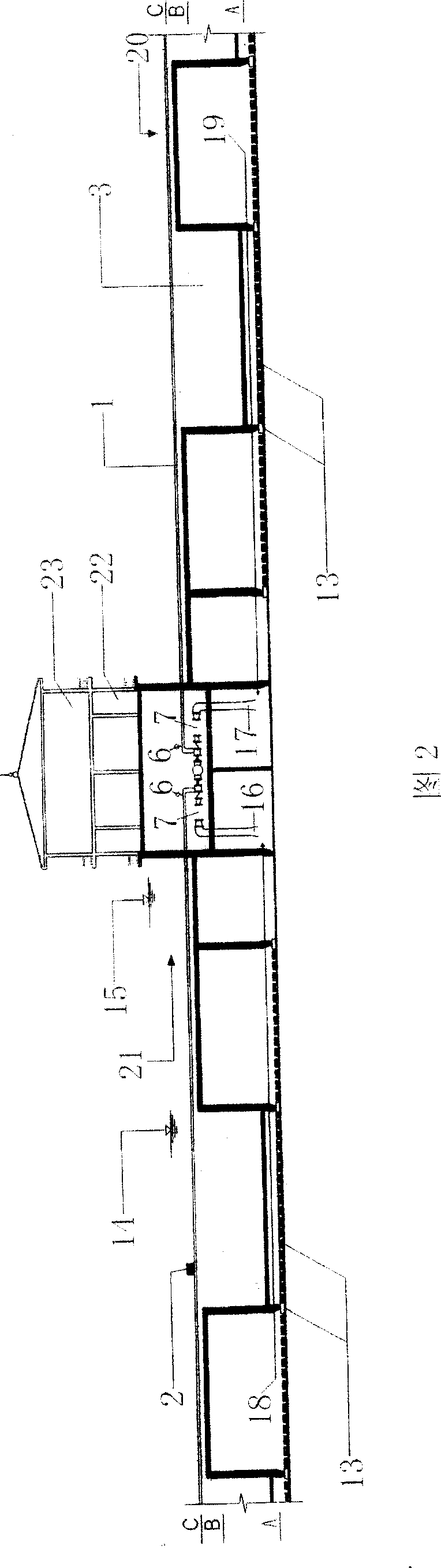

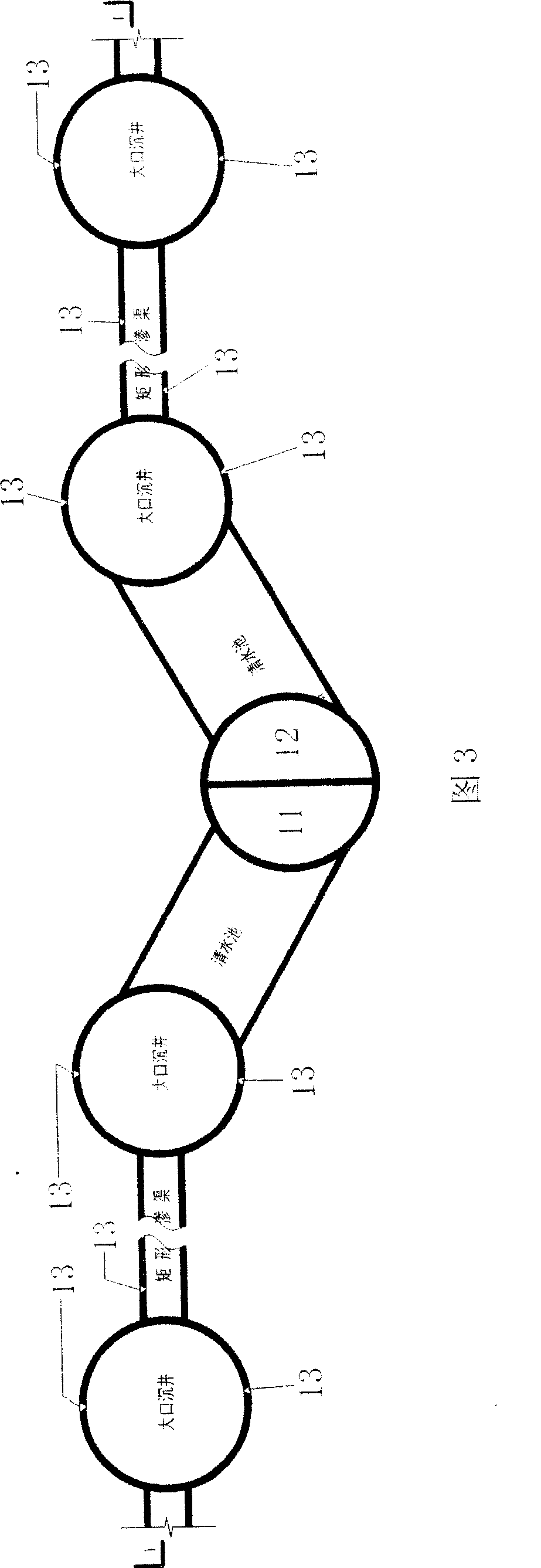

[0027] As shown in Figures 1 to 5, the construction method of using backwashing in the filter layer of the water purification building includes "a caisson construction method for stabilizing water volume" announced by the prior patent CN1067132C and "in the Groundwater intake project aquifer is equipped with the construction method of rectangular infiltration canal " carry out construction, comprise according to the upper and lower reaches of the river channel namely the flow direction of the river 21 divide described water purification building into the upper and lower half nets respectively connected with the upper and lower river channels Water building 11,12, the water inlet direction 18,19 of upper and lower half water purification building 11,12 as shown in Figure 2. The upper and lower half water purification buildings 11 and 12 are equipped with a backwash pipeline 1, one end of which is provided with a valve 7 and a pressure gauge 6 to control the water volume and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com