Device for measuring liner thickness of trunnion dirction for rotary furnace and measuring method thereof

A converter and trunnion technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of high price, high failure rate, and many restrictive links in the measurement, and achieve the effect of simple production, flexible operation, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

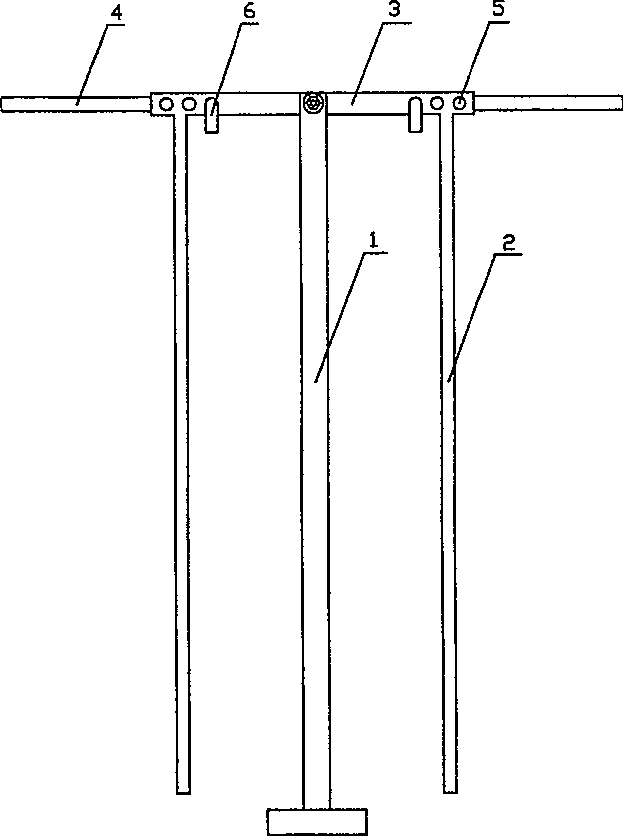

[0015] A device for measuring the thickness of the furnace lining in the direction of the trunnion of the converter, such as figure 1 As shown, it includes a measuring rod 1, two pull rods 2, a rotatable measuring rod 3, and two variable measuring rods 4. The measuring rod 1 is flexibly connected with the rotatable measuring rod 3, and the two pull rods 2 are respectively fixed on The two ends of the rotatable measuring rod 3, the rotatable measuring rod 3 is a hollow tube, the two ends are provided with a plurality of positioning holes 5, the outer diameter of the variable measuring rod 4 is smaller than the inner diameter of the rotatable measuring rod 3, and one end A plurality of positioning holes 5 are provided, which are fixed in the tube of the rotatable measuring pole 3 by fixing pins 6 .

[0016] figure 1 The device shown is used to measure the thickness of the furnace lining in the trunnion direction of the converter. The measurement method is to turn the converter ...

specific Embodiment approach 2

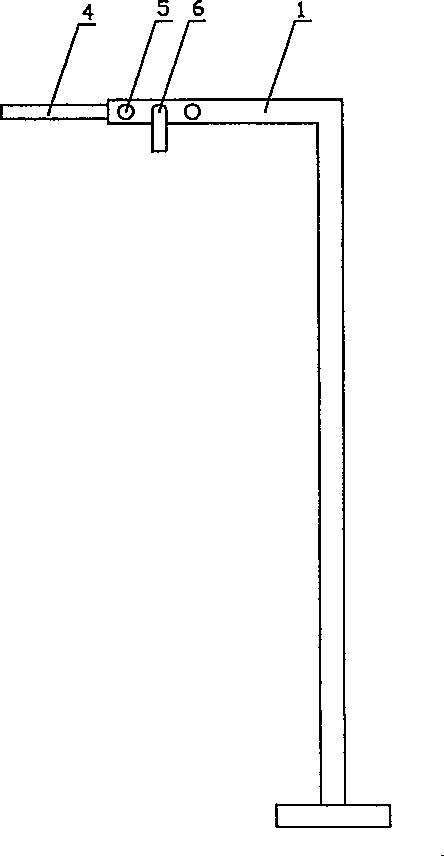

[0017] A converter furnace body measuring instrument, such as figure 2 As shown, including measuring pole 1, variable measuring pole 4, positioning hole 5, fixed pin 6, measuring pole 1 is a hollow tube, the outer diameter of variable measuring pole 4 is smaller than the inner diameter of measuring pole 1, and one end is set There are a plurality of positioning holes 5, which are fixed in the tube of the measuring pole 1 by fixing pins 6.

[0018] figure 2 The converter furnace body measuring device shown is used to measure the thickness of the large-surface lining of the converter. The measurement method is to turn the converter to 90 degrees, place the measuring rod 1 on the center line of the converter, and after the variable measuring rod 4 is in full contact with the furnace lining, Fix the position of the variable measuring rod 4 in the pipe of the support rod 1 with the fixed pin 5, measure the vertical length from the end point of the support rod 1 to the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com